Absolute Rotary Encoder

Programmable Parameters

2017-04

55

9.5.46 Object 3040h: Life Cycle Counter

Diagnostic value to monitor, if the position value is updated compared to last transmission. This

feature is interesting for safety applications to detect for example, if the value in the CAN

controller is frozen. The value starts at power up with 0 and is continuously incremented. When

overflow is reached, then it starts again with 0. It is not expected, that the transmitted value is

incremented, because the life cycle counter is handled in the function when the position value

is measured and this process is asynchronous to the CAN communication.

9.5.47 Object 3050h: Time Stamp Position Value

This time stamp is generated when the position value is measured. Like the life cycle counter

this value can be used for safety purposes to detect stuck at effects. Another feature is to

calculate the velocity on PLC side with accurate time stamp values to achieve high accuracy for

individual requirements. It offers more flexibility than the encoder internal pre-defined velocity

measurement.

Time resolution is 1 µs.

9.5.48 Object 4000h: Bootloader Control

This object controls the Bootloader functionality (see Bootloader chapter). Writing the security

code to this object causes erasing the EEPROM and application information in the flash

memory and resets the device. After a power-up, the Bootloader checks the user application

and detects no more information. The Bootloader starts up with a pre-defined CANopen node

ID of 1 (0x1) and a fixed CAN baud rate of 125 kbits.

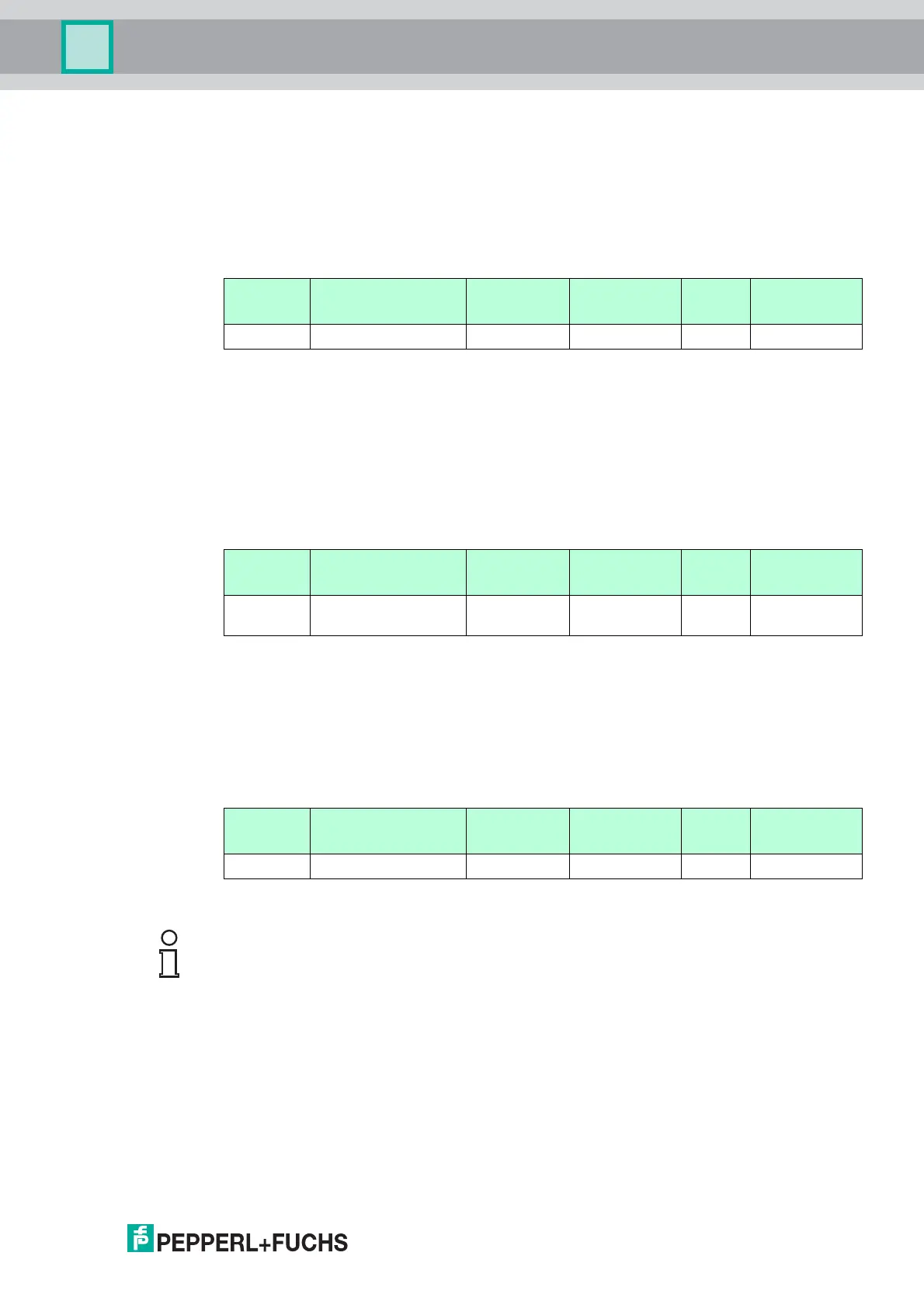

Subindex Description Data Type Default Value Access

Restore after

Boot up

0h Life Cycle Counter Unsigned 32 romap o

Ta b l e 9 . 6 1

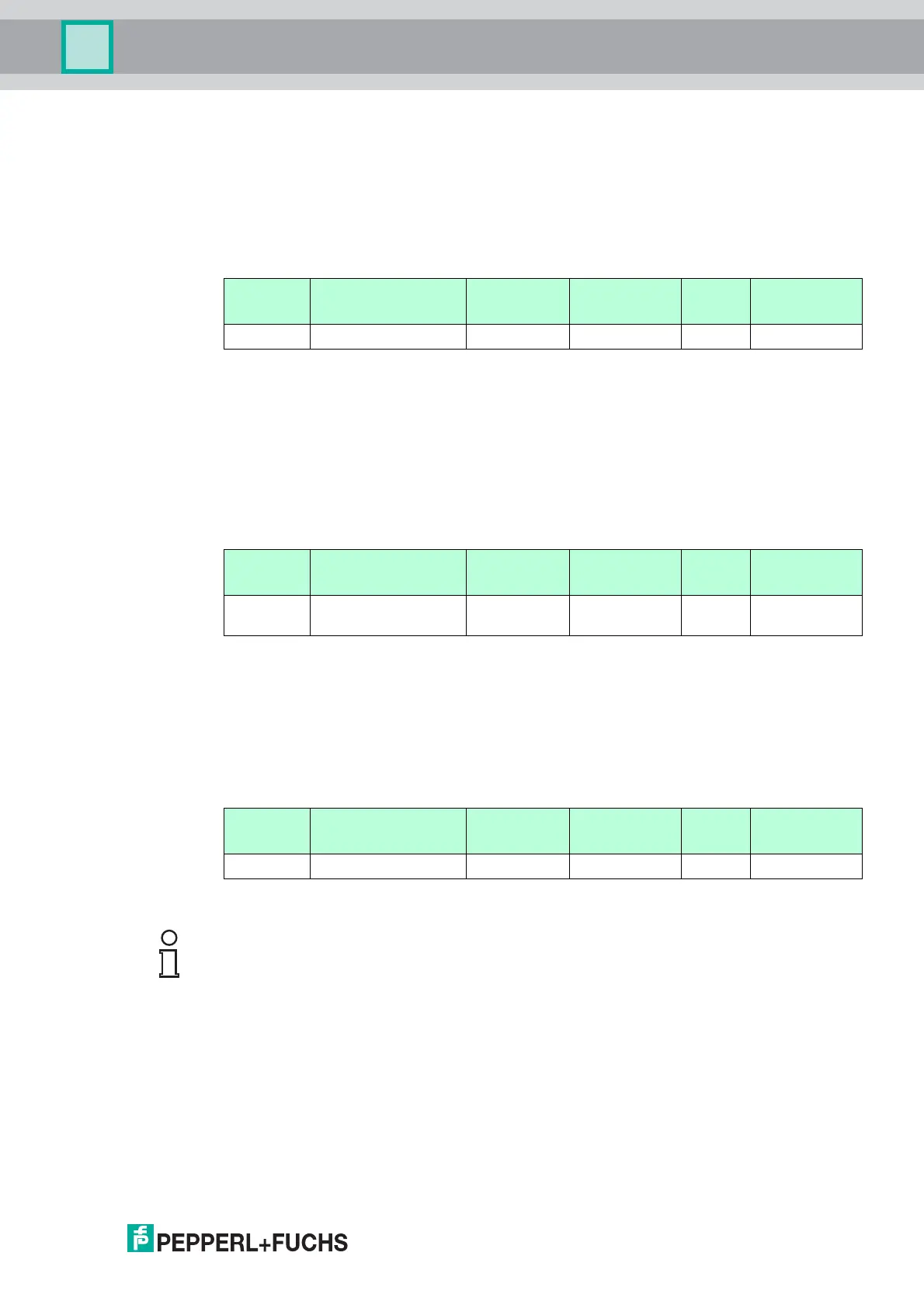

Subindex Description Data Type Default Value Access

Restore after

Boot up

0h Time Stamp Postion

Value

Unsigned 32 romap

Ta b l e 9 . 6 2

Subindex Description Data Type Default Value Access

Restore after

Boot up

0h Bootloader Control Unsigned 32 wo

Ta b l e 9 . 6 3

Note!

Activating the Bootloader courses a deep reset of the device. After this only a few objects are

still available, the device does not behave like an encoder and waits for new programming. That

is the reason why the security code is not published in this document. Please contact

Peppel+Fuchs to obtain the code.

Loading...

Loading...