SEBU8605-01 65

Maintenance Section

Refill Capacities

•

Independent la

boratory

Additives

Additives help to protect the metal surfaces of

the cooling system. A lack of coolant additives or

insufficient

amounts of additives enable the following

conditions to occur:

•

Corrosion

•

Formation of mineral deposits

•

Rust

•

Scale

•

Foaming of the coolant

Many additives are depleted during engine operation.

These additives must be replaced periodically.

Additives must be added at the correct concentration.

Over concentration of additives can cause the

inhibit

ors to drop out-of-solution. The deposits can

enable the following problems to occur:

•

Formati

on of gel compounds

•

Reduction of heat transfer

•

Leakage of the water pump seal

•

Pluggi

ng of radiators, coolers, and small passages

Glycol

Glycol in the coolant helps to provide protection

against the following conditions:

•

Boiling

•

Free

zing

•

Cavitation of the water pump

For optimum performance, Perkins recommends a

1:1 mixture of a water/glycol solution.

Note: Use a mixture that will provide protection

against the lowest ambient temperature.

Note: 100 percent pure glycol will freeze at a

temperature of −13 °C (8.6 °F).

Most conventional antifreezes use ethylene glycol.

Propylene glycol may also be used. In a 1:1 mixture

wi

th water, ethylene and propylene glycol provide

similar protection against freezing and boiling. Refer

to Table 9 and refer to table 10.

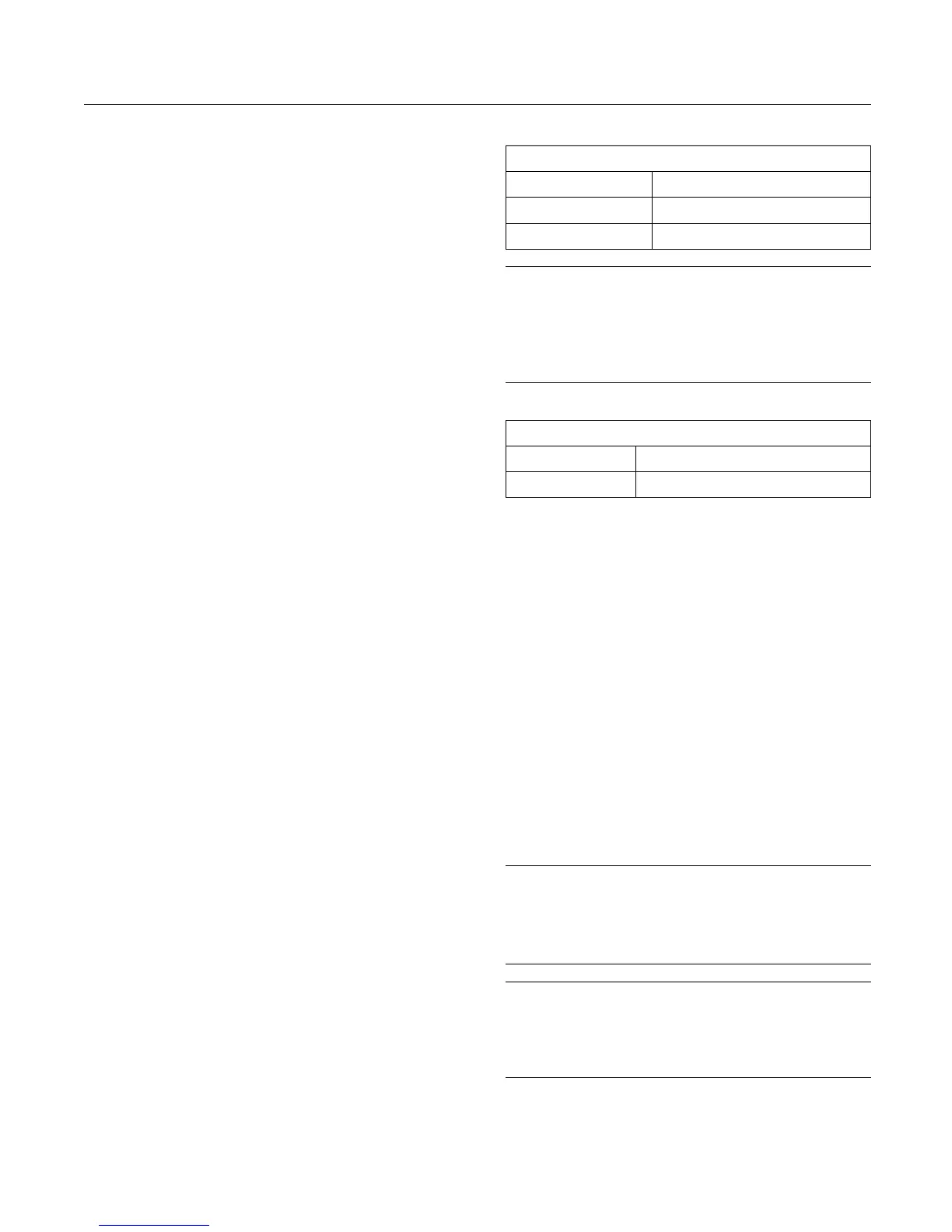

Table 9

Ethylene Glycol

Concentration Freeze Protection

50 Percent −36 °C (−33 °F)

60 Percent

−51 °C (−60 °

F)

NOTICE

Do not use propylene glycol in concentrations that ex-

ceed 50 percent glycol because of the reduced heat

transfer capability of propylene glycol. Use ethylene

glycol in conditions that require additional protection

against boiling or freezing.

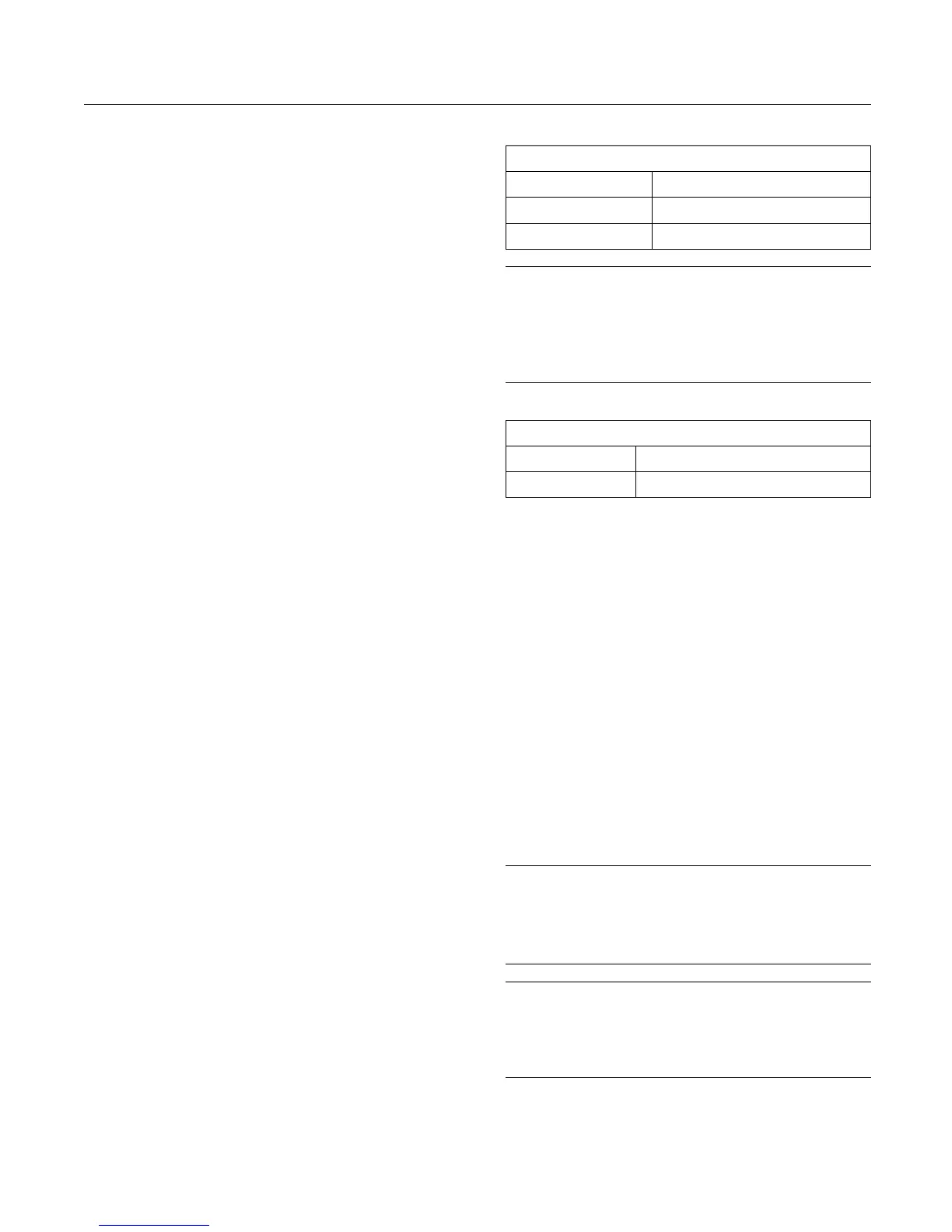

Table 10

Propylene Glycol

Concentration Freeze Protection

50 Percent −29 °C (−20 °F)

To check the concentration of glycol in the coolant,

measure the specific gravity of the coolant.

Coolant Recommendations

•

ELC____________________________ Extended Life Coolant

•

SCA___________________ Supplement Coolant Additive

•

ASTM__________________________________________ American

Society for Testing and Materials

The following two coolants are used in Perkins diesel

engines:

Preferred – Perkins ELC

Acceptable – A commercial heavy-duty antifreeze

that meets “ASTM D6210 ” specifications

NOTICE

The 1200 series industrial engines must be oper-

ated with a 1:1 mixture of water and glycol. This

concentration allows the N Ox reduction system to

operate correctly at high ambient temperatures.

NOTICE

Do not use a commercial coolant/antifreeze that on-

ly meets the ASTM D3306 specification. This type of

coolant/antifreeze is made for light automotive appli-

cations.

Perkins recommends a 1:1 mixture of water and

glycol. This mixture of water and glycol will provide

optimum heavy-duty performance as an antifreeze.

This ratio may be increased to 1:2 water to glycol if

extra freezing protection is required.

Loading...

Loading...