96 SEBU8605-01

Maintenance Section

Engine Oil Level - Check

Any engine moun

t that shows deterioration should

be replaced. Refer to the OEM information for the

recommended torques.

i03996001

Engine Oil Level - Check

Hot oil and

hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

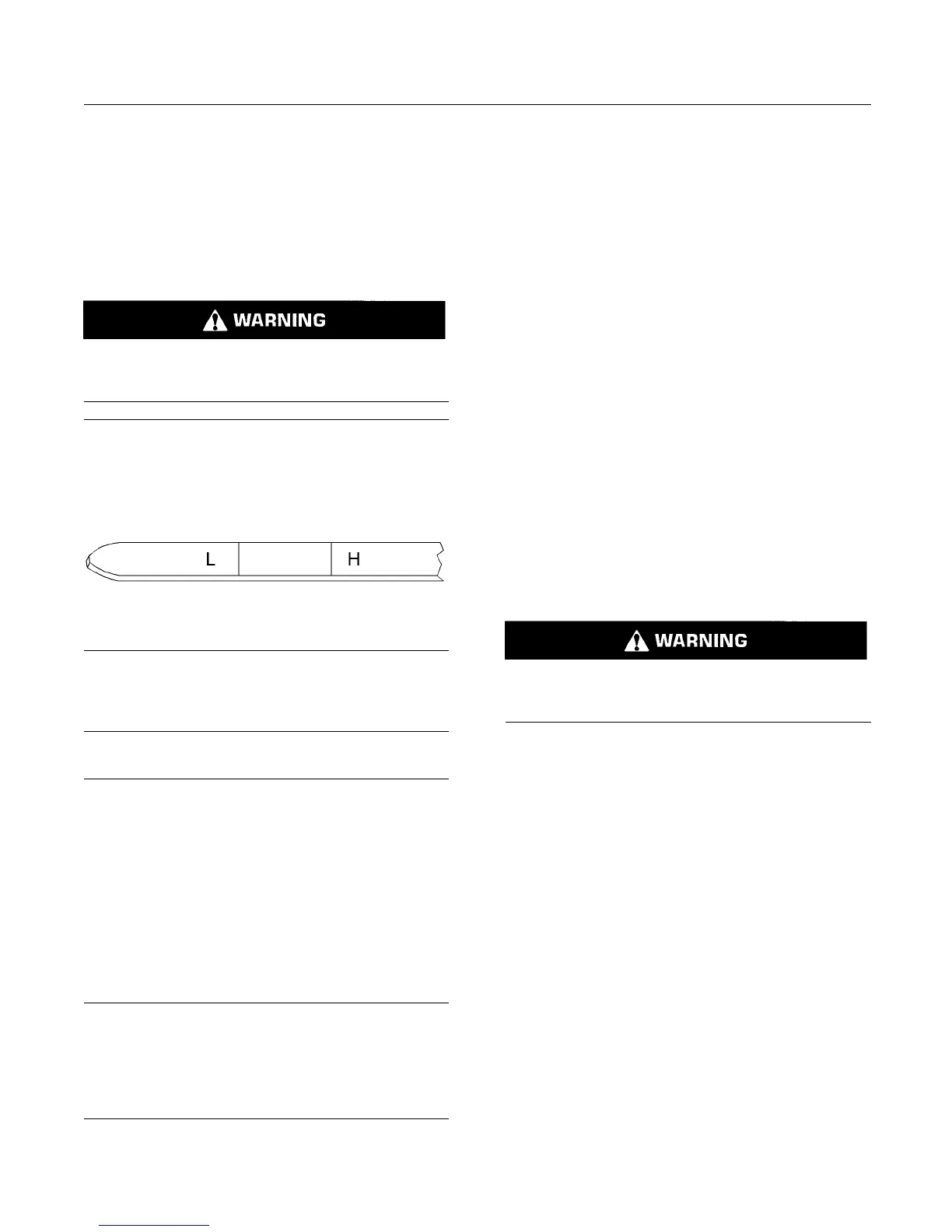

g0217

3847

Illustration 63

“L” Low

“H” Hi

gh

NOTICE

Perform this maintenance with the engine stopped.

Note: Ensure that the engine is either level or that

the engine is in the normal operating position in order

to obtain a true level indication.

Note: After the engine has been switched OFF, wait

for 10 minutes in order to allow the engine oil to drain

to the oil pan before checking the oil level.

1. Maintain the oil level between the mark (L) and

the mark (H) on the engine oil dipstick. Do not fill

the crankcase above the “H”.

NOTICE

Operating your engine when the oil level is above the

“FULL” mark could cause your crankshaft to dip into

the oil. The air bubbles created from the crankshaft

dipping into the oil reduces the oil's lubricating char-

acteristics and could result in the loss of power.

2. Remove the oil fi ller cap and add oil, if necessary.

Clean the oil filler cap. Install the oil filler cap.

If an increase i

n the oil level is noticed, refer to

Troubleshooting, “Oil Contains Fuel”.

i01907674

Engine Oil Sample - Obtain

The condition of the engine lubricating oil may be

checked at regular intervals as part of a preventive

maintenance program. Perkins include an oil

sampling valve as an option. The oil sampling valve

(if equipped) is included in order to regularly sample

the engine lubricating oil. The oil sampling valve is

positioned on the oil filter head or the oil sampling

valve is positioned on the cylinder block.

Perkins recommends using a sampling valve in order

to obtain oil samples. The quality and the consistency

of the samples are better when a sampling valve is

used. The location of the sampling valve allows oil

that is flowing under pressure to be obtained during

normal engine operation.

Obtain the Sample and the Analysis

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

In order to help obtain the most accurate analysis,

recordthefollowinginformationbeforeanoilsample

is taken:

•

The date of the sample

•

Engine model

•

Engine number

•

Service hours on the engine

•

The number of hours that have accumulated since

the last oil change

•

The amount of oil that has been added since the

last oil change

Ensure that the container for the sample is clean and

dry. Also ensure that the container for the sample is

clearly labelled.

To ensure that the sample is representative of the

oil in the crankcase, obtain a warm, well mixed oil

sample.

Loading...

Loading...