72 SEBU8605-01

Maintenance Section

Refill Capacities

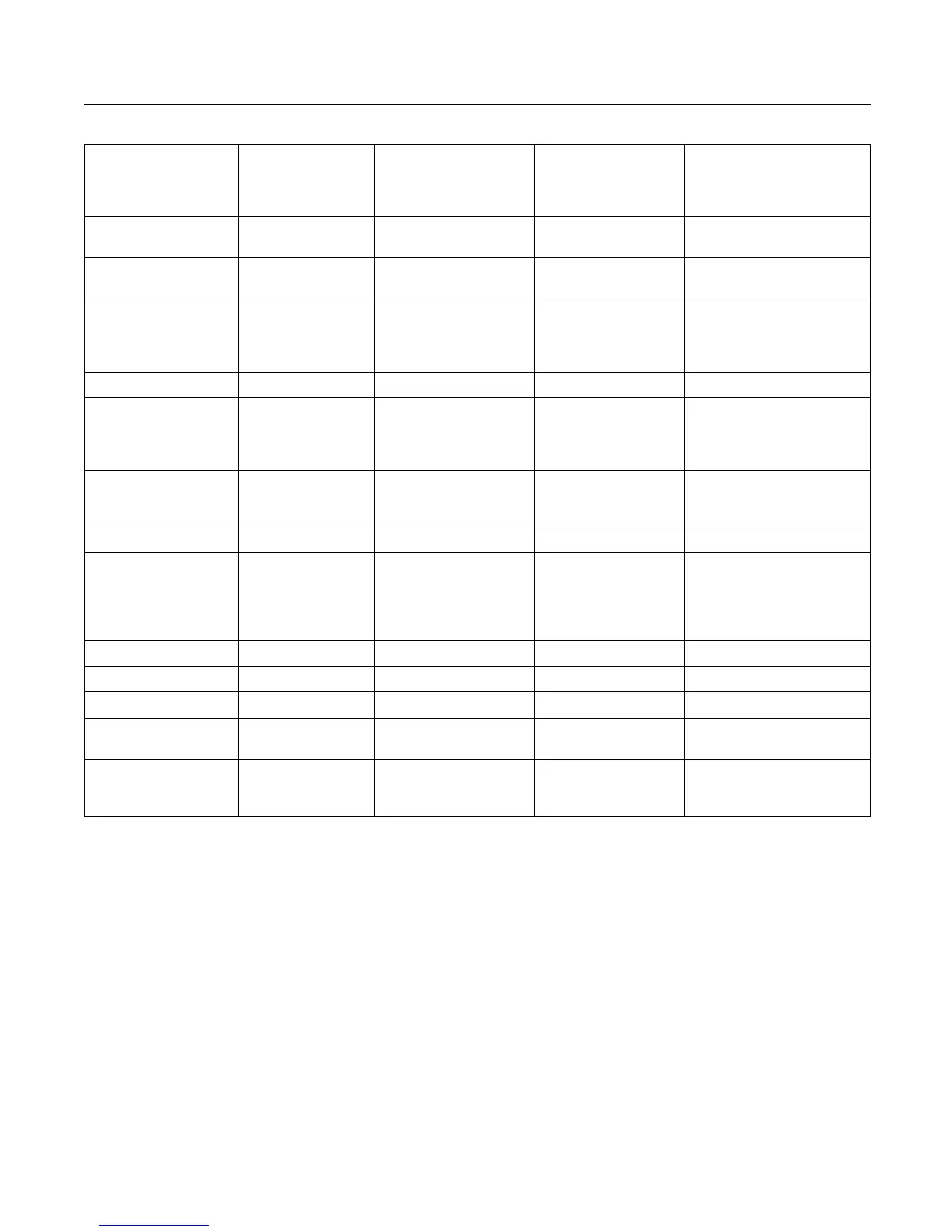

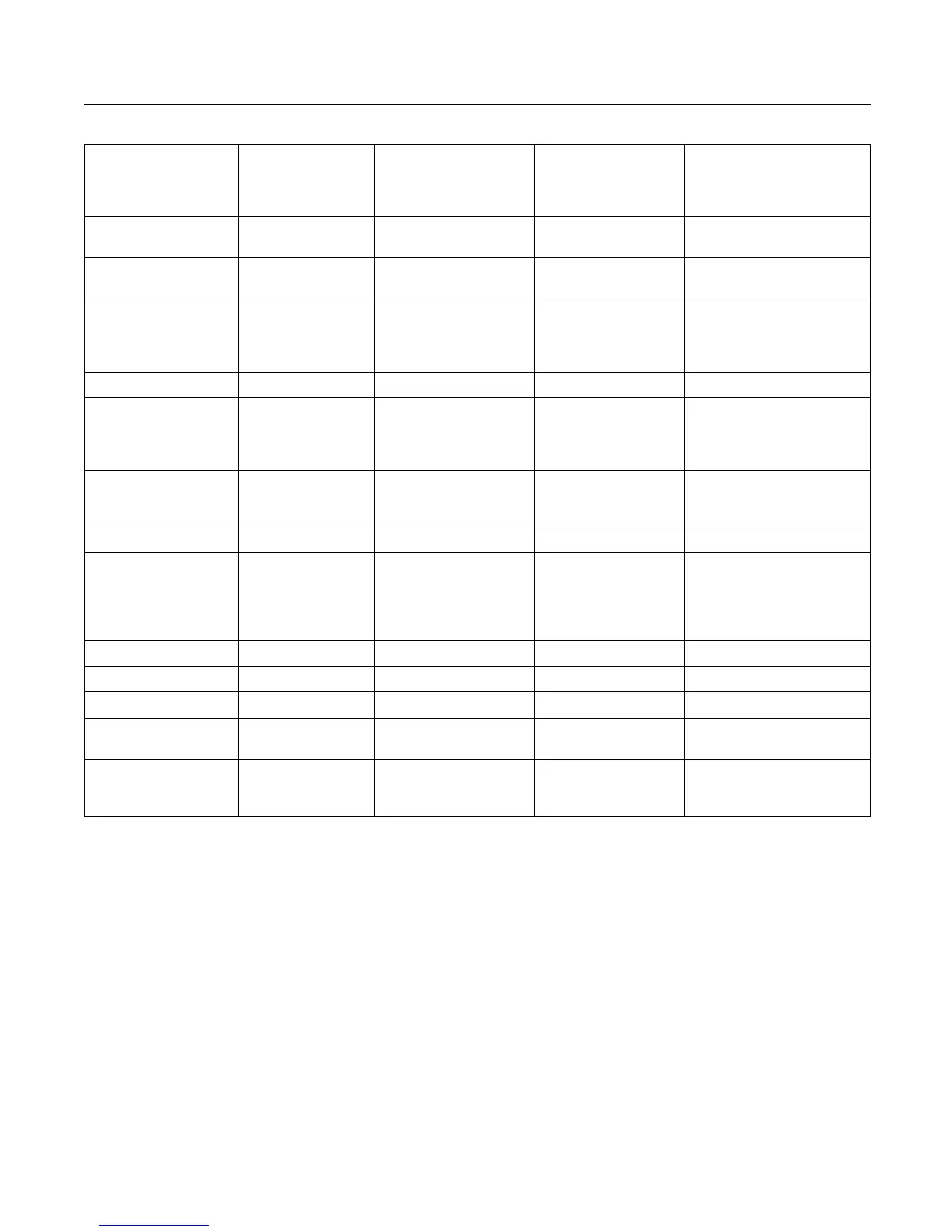

(Table 17, contd)

Cloud Point °C

The cloud point must

not exceed the

lowest

expected ambient

temperature.

D2500

“ISO”3015

Copper Strip

Corrosion

-

No. 3 maximum D130 “ISO”2160

Density at 15 °C

(59 °F)

(3)

Kg / M

3

801 minimum and 876

maximum

No equivalent test

“ISO 3675 ”“ISO 12185”

Distillation

°C 10% at 282 °C

(539.6 °F) maximum

90% at 360 °C (680 °F)

maximum

D86

“ISO”3405

Flash Point

°C

legal limit D93

“ISO”2719

Thermal Stability

-

Minimum of 80%

reflectance after aging

for 180 minutes at

150 °C (302 °F)

D6468 No equiva

lent test

Pour Point °C 6 °C (42.8 °F) minimum

below ambient

temperature

D97 “ISO”3016

Sulfur

(1)

%mass

0.0015

D5453/D26222 “ISO 20846 ”“ISO 20884”

Kinematic Viscosity

(4)

“MM”

2

“/S (cSt)” The viscosity of the

fuel t

hat is delivered to

the fuel injection pump.

“1.4 minimum/4.5

maxim

um”

D445

“ISO”3405

Water and sediment

% weight 0.1% maximum

D1796

“ISO”3734

Water

% weight 0.1% maximum

D1744 No equivalent test

Sediment % weight 0.05% maximum

D473

“ISO”3735

Gums and Resins

(5)

mg/100mL

10 mg per 100 mL

maximum

D381

“ISO”6246

Lubricity corrected

wear scar diameter at

60 °C (140 °F).

(6)

mm

0.52 maximum D6079

“I

SO”12156-1

(1)

This specific ation includes the requirements for Ultra Low Sulfur Diesel (ULSD). ULS D fuel will have ≤ 15 ppm (0.0015%) sulfur. Refer to

“ASTM D5453”, “ASTM D2622”, or “ISO 20846, ISO 20884” test methods.

(2)

A fuel with a higher cetane number is recommended in or der to op erate at a higher altitude or in cold weather.

(3)

“Via standards tables, the equivalent API gr avity for the m inimum density o f 801 kg / m

3

(kilograms per cu bic meter) is 45 and for the

maximum density o f 876 k g / m

3

is 30”.

(4)

The v alues of the fuel viscosity are the values as the fuel is delivered to the fuel injection pumps. Fuel should also meet the minimum

viscosity requirement and the fuel should m eet the maximum viscosity requirements at 40 °C (104 °F) of either the “ASTM D445” test

method or the “ISO 3104” test method. If a fuel w ith a low viscosity is used, cooling of the fuel m ay be r equired to maintain “1.4 cSt”or

greater viscosity at the fuel injection pum p. Fuels with a high viscosity m ight r equire fuel heaters in order to lower the v iscosity to “1.4

cSt” at the fuel injection pump.

(5)

Follow the test conditions and procedures for gas oline (motor).

(6)

The lubricity of a fuel is a concern with ultra low sulfur fuel. To determine the lubricity of t he fuel, use the “ISO 12156-1 or AST M D6079

High Frequency Rec iprocating Rig (HFRR)” test. If the lubricity of a fuel does not meet the m inimum requirements, consult your fuel

supplier. Do not treat the fuel without consulting the fuel supplier. Some additives are not com patible. These additives can ca use

problems in the fuel system.

Engines that are manufactured by Perkins are

certified with the fuel that is prescribed by the United

States Environmental Protection Agency. Engines

that are manufactured by Perkins are certified

with the fuel that is prescribed by the European

Certification. Perkins does not certify diesel engines

on any other fuel.

Note: The owner and the operator of the engine has

the responsibility of using the fuel that is prescribed by

the EPA and other appropriate regulatory agencies.

Loading...

Loading...