98 SEBU8605-01

Maintenance Section

Engine Oil and Filter - Change

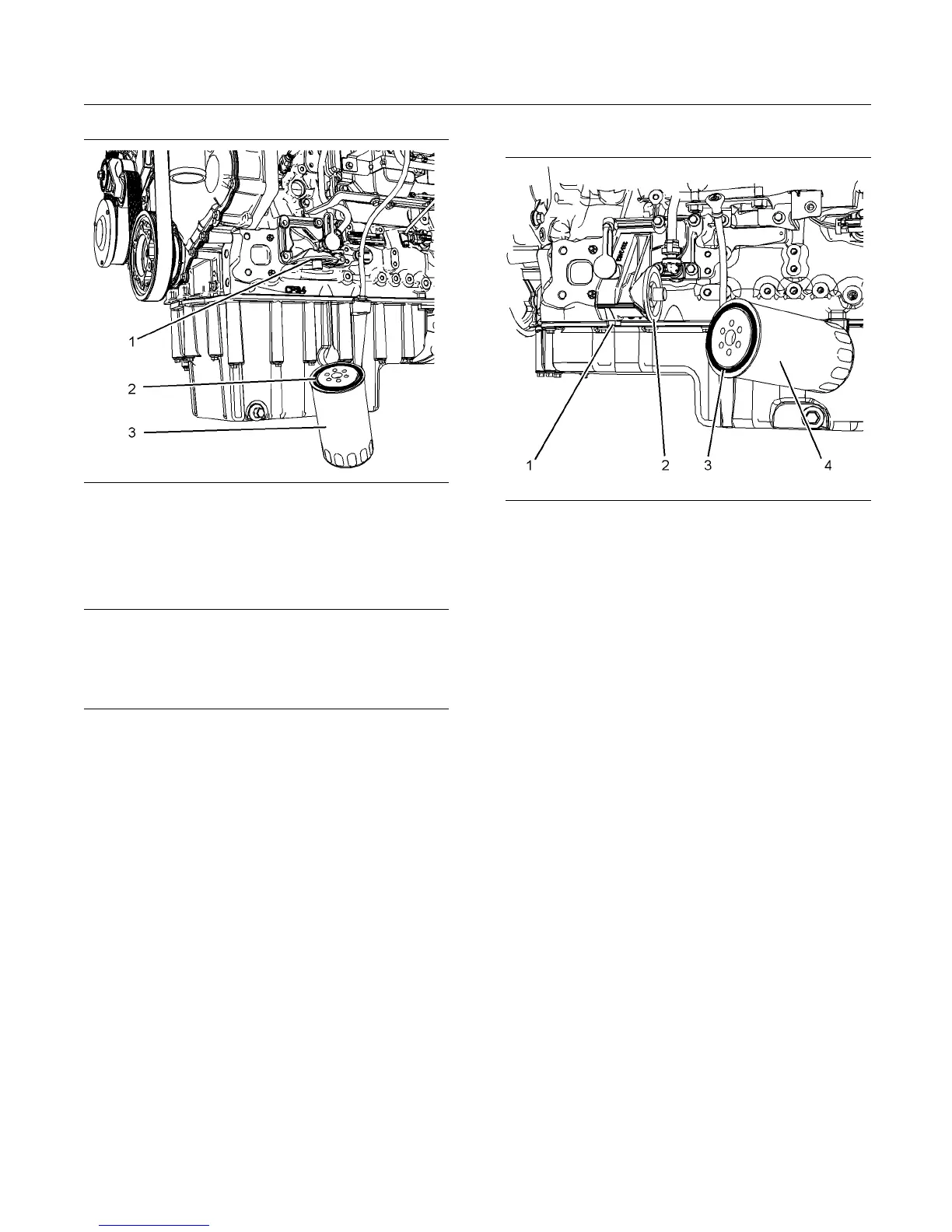

g02131364

Illustration 65

2. Clean sealing surface (1).

3. Apply clean engine oil to O ring seal (2) for the

new oil filter (3).

NOTICE

Do not fill the oil filters with oil before installing them.

This oil would not be filtered and could be contaminat-

ed. Contaminated oil can cause accelerated wear to

engine components.

4. Install the new oil filter (3). Spin on the oil filter

until the O ring contacts the sealing surface (2).

Then rotate the oil filter ¾ of a full turn. Remove

the container and disposal of the waste oil in

accordance with local regulations.

Horizontal Oil

Filter

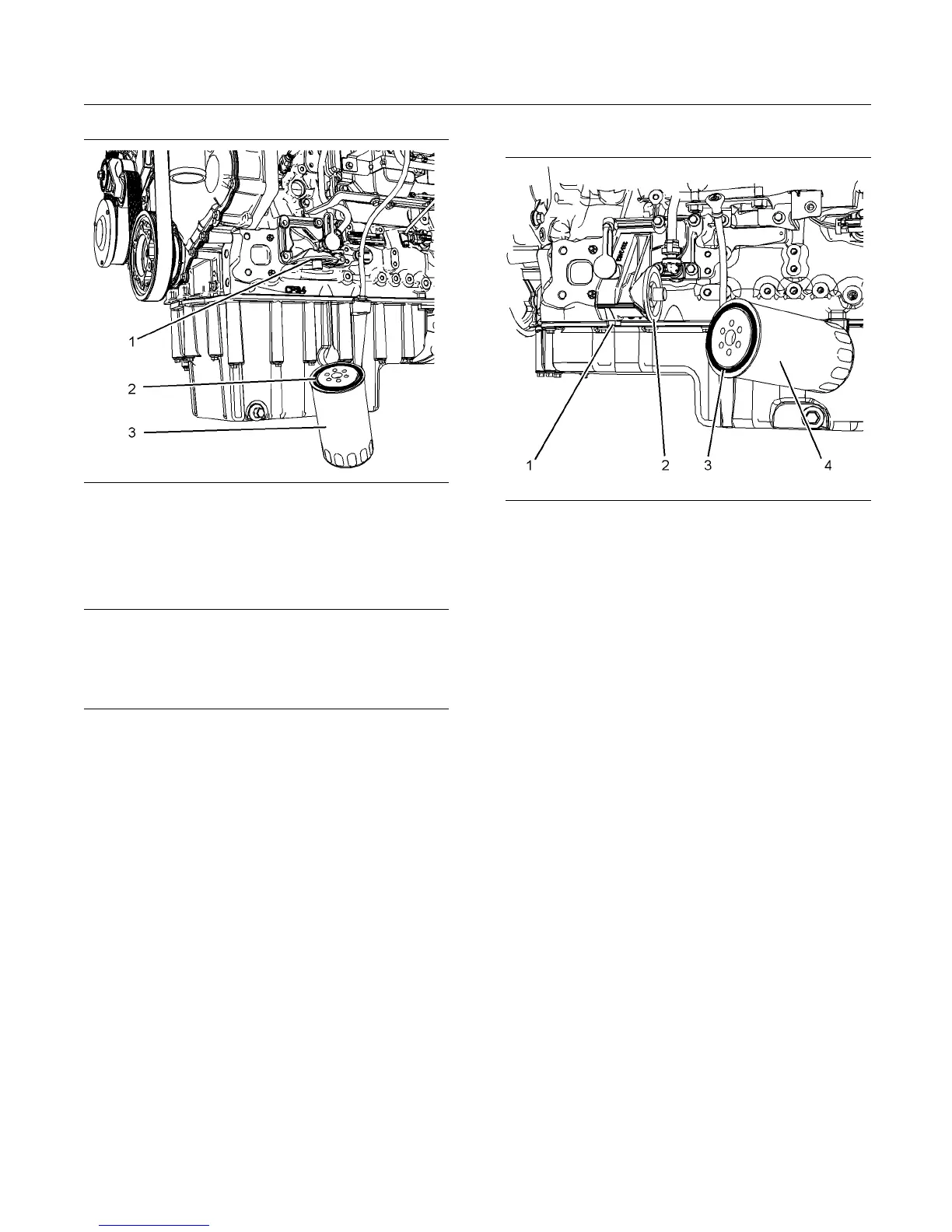

g02132333

Illustration 66

1. Place a suitable container below the oil filter

assembly. Remove the drain plug (1) and allow

the oil to drain.

2. Remove the oil filter with a suitable tool.

Note: The following actions can be carried out as

part of the preventive maintenance program.

3. Cut the oil filter open with a suitable tool. Break

apart the pleats and inspect the oil filter for metal

debris. An excessive amount of metal debris in

the oil filter may indicate early wear or a pending

failure.

Use a magnet to differentiate between the ferrous

metals and the nonferrous metals that are found in

the oil filter element. Ferrous metals may indicate

wear on the steel and cast iron parts of the engine.

Nonferrous metals may indicate wear on the

aluminum parts, brass parts, or bronze parts of

the engine. Parts that may be affected include the

following items: main bearings, rod bearings, and

turbocharger bearings.

Due to normal wear and friction, it is not

uncommon to find small amounts of debris in the

oil filter.

4. Install the drain plug (1) and tighten to a torque of

12 N·m (106 lb in).

5. Clean the sealing surface (2).

Loading...

Loading...