38 SEBU8337

Maintenance Section

Refill Capacities

Maintenance Section

Refill Capacities

i02793514

Refill Capaci ties

Lubrication System

The refill capacities for the engine crankcase

reflect the approximate capacity of the crankcase

or sump plus standard oil filters. Auxiliary oil filter

systems will require additional oil. Refer to the OEM

specifications for the capacity of the auxiliary oil filter.

Refer to the Operation and Maintenance Manual,

“Maintenance Section” for more information on

Lubricant Specifications.

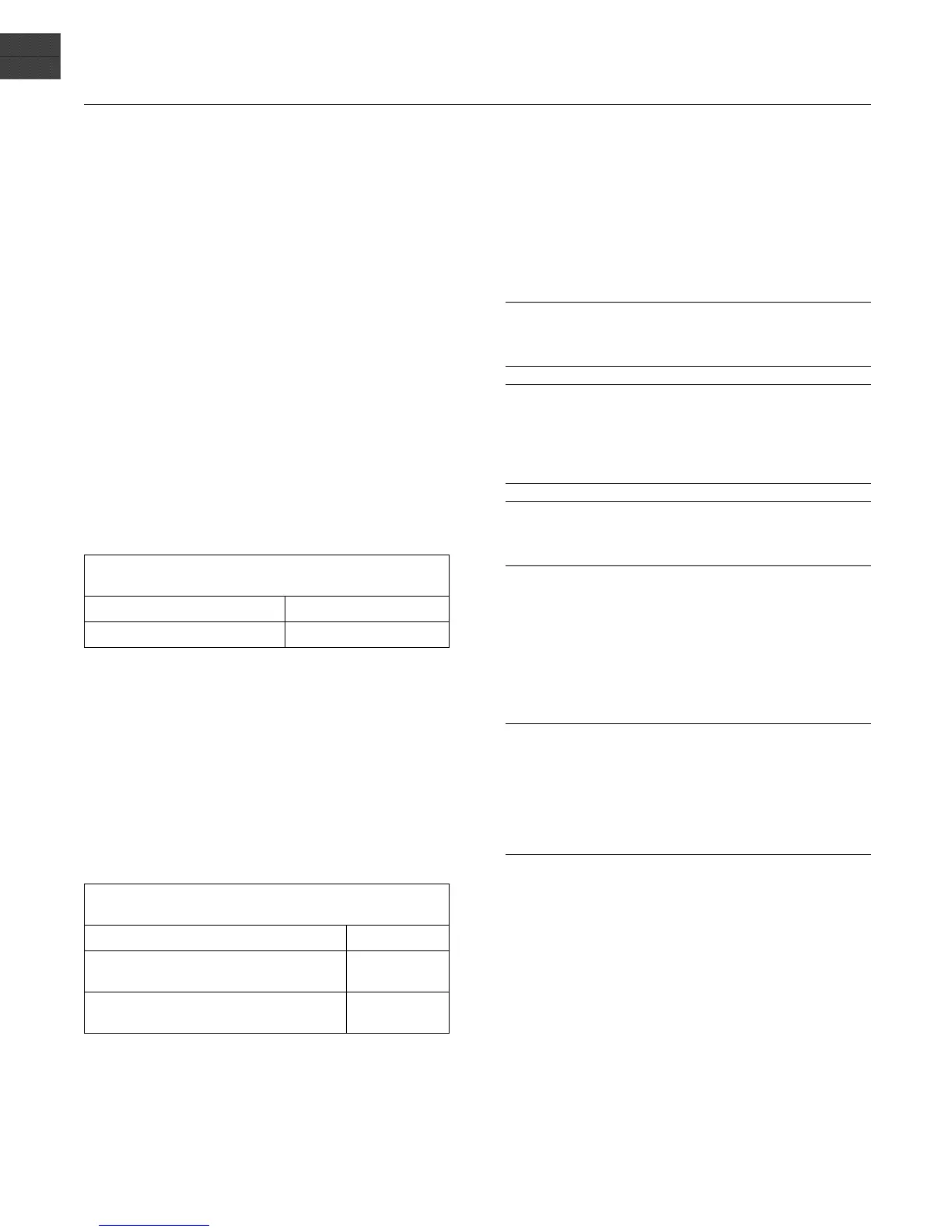

Table 3

Engine

Refill Capacities

Compartment or System

Maximum

Crankcase Oil Sump

(1)

40 L (8.8 Imp gal)

(1)

These values are the approximate c apacities for the crankcase

oil sump (aluminum) which includes the standard factory

installed o il filters. Engines with auxiliary oil filters will require

additional oil. Refer to the OEM specifications for the capacity

of the auxiliary oil filter .

Cooling System

Refer to the OEM specifications for the External

System capacity. This capacity information will be

needed in o

rder to determine the amount of coolant

that is required for the Total Cooling System.

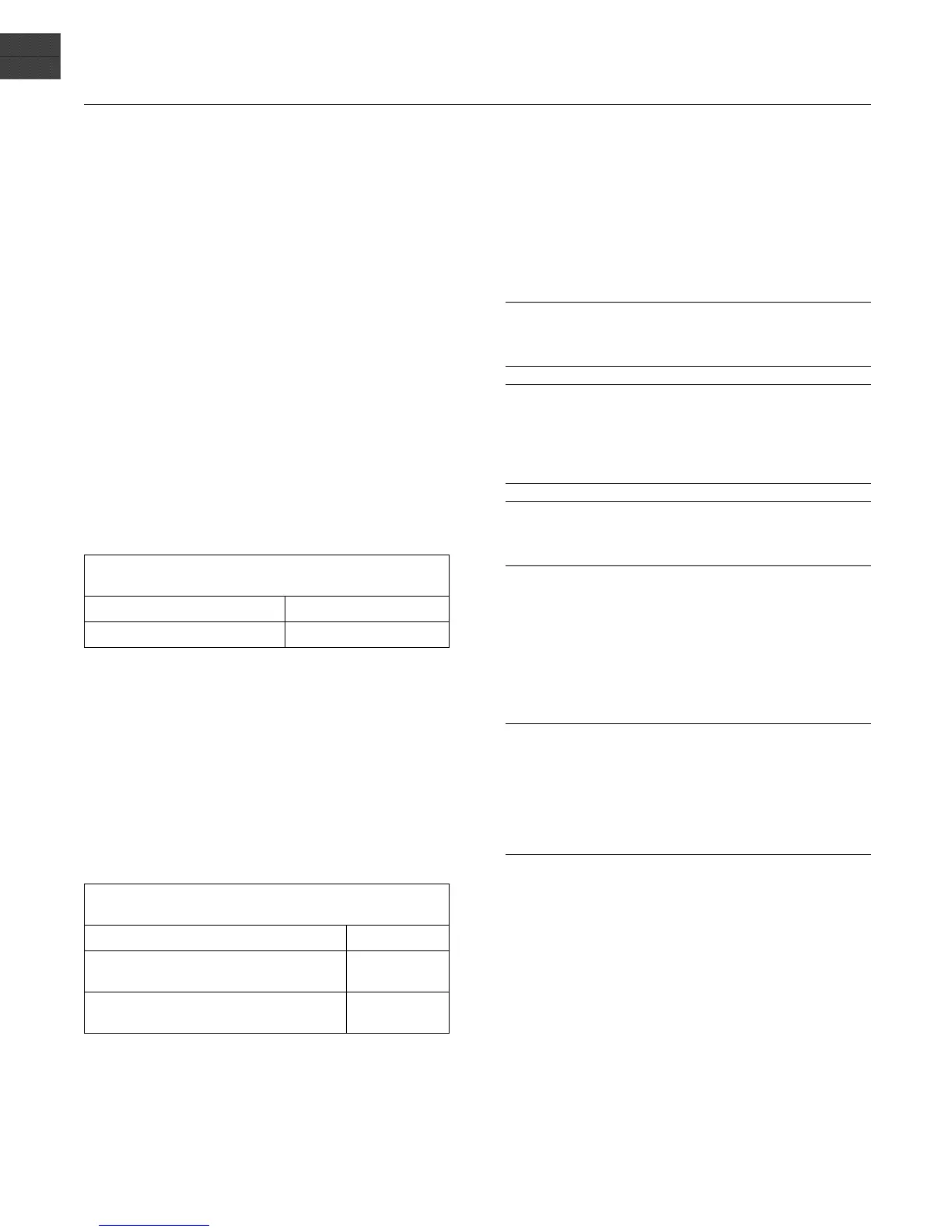

Table 4

Engine

Refill Capacities

Compartment or System Liters

Engine Only

15 L

(3.3 Imp gal)

External System Per OEM

(1)

25.5 L

(5.6 Imp gal)

(1)

The External System includes a radiator or an expansion

tank w ith the following components: heat exchanger and

piping. Refer to the OEM specifications. Enter the value for the

capacity of the External System in this row.

i03040206

Fluid Recommendations

Cooling System Specifications

General Coola

nt Information

NOTICE

Never add coolant to an overheated engine. Engine

damage could result. Allow the engine to cool first.

NOTICE

If the engine is to be stored in, or shipped to an area

with below free

zing temperatures, the cooling system

must be either protected to the lowest outside temper-

ature or drained completely to prevent damage.

NOTICE

Frequently check the specific gravity of the coolant for

proper freeze protection or for anti-boil protection.

Clean the cooling system for the following reasons:

•

Contamination of the cooling system

•

Overheating o

f the engine

•

Foaming of the coolant

NOTICE

Never operate an engine without water temperature

regulators in the cooling system. Water temperature

regulators he

lp to maintain the engine coolant at the

proper operating temperature. Cooling system prob-

lems can develop without water temperature regula-

tors.

Many engine failures are related to the cooling

system. The following problems are related to cooling

system failu

res: Overheating, leakage of the water

pump, and plugged radiators or heat exchangers.

These failur

es can be avoided with correct cooling

system maintenance. Cooling system maintenance is

as important as maintenance of the fuel system and

the lubrica

tion system. Quality of the coolant is as

important as the quality of the fuel and the lubricating

oil.

Coolant is normally composed of three elements:

Wa ter, additives, and glycol.

Loading...

Loading...