70 SEBU8337

Maintenance Section

Engine Protective Devices - Check

i02568161

Engine Protectiv e D evi ces -

Check

Visual Inspection

Visually check the condition of all gauges, sensors

and wiring. Look for wiring and components that

are loose, bro

ken, or damaged. Damaged wiring

or components should be repaired or replaced

immediately.

Calibration Check

NOTICE

During testing, abnormal operating conditions must be

simulated.

The tests must be performed correctly in order to pre-

vent possibl

e damage to the engine.

Alarms and shutoffs must function properly. Alarms

provide time

ly warning to the operator. Shutoffs help

to prevent damage to the engine. It is impossible

to determine if the engine protective devices are

in good work

ing order during normal operation.

Malfunctions must be simulated in order to test the

engine protective devices. To prevent damage to the

engine, onl

y authorized service personnel or your

Perkins distributor should perform the tests.

Consult yo

ur Perkins distributor or refer to the Service

Manual for more information.

i02790456

Engine Speed/Timing Sensors

- C heck/Clean

/Calibrate

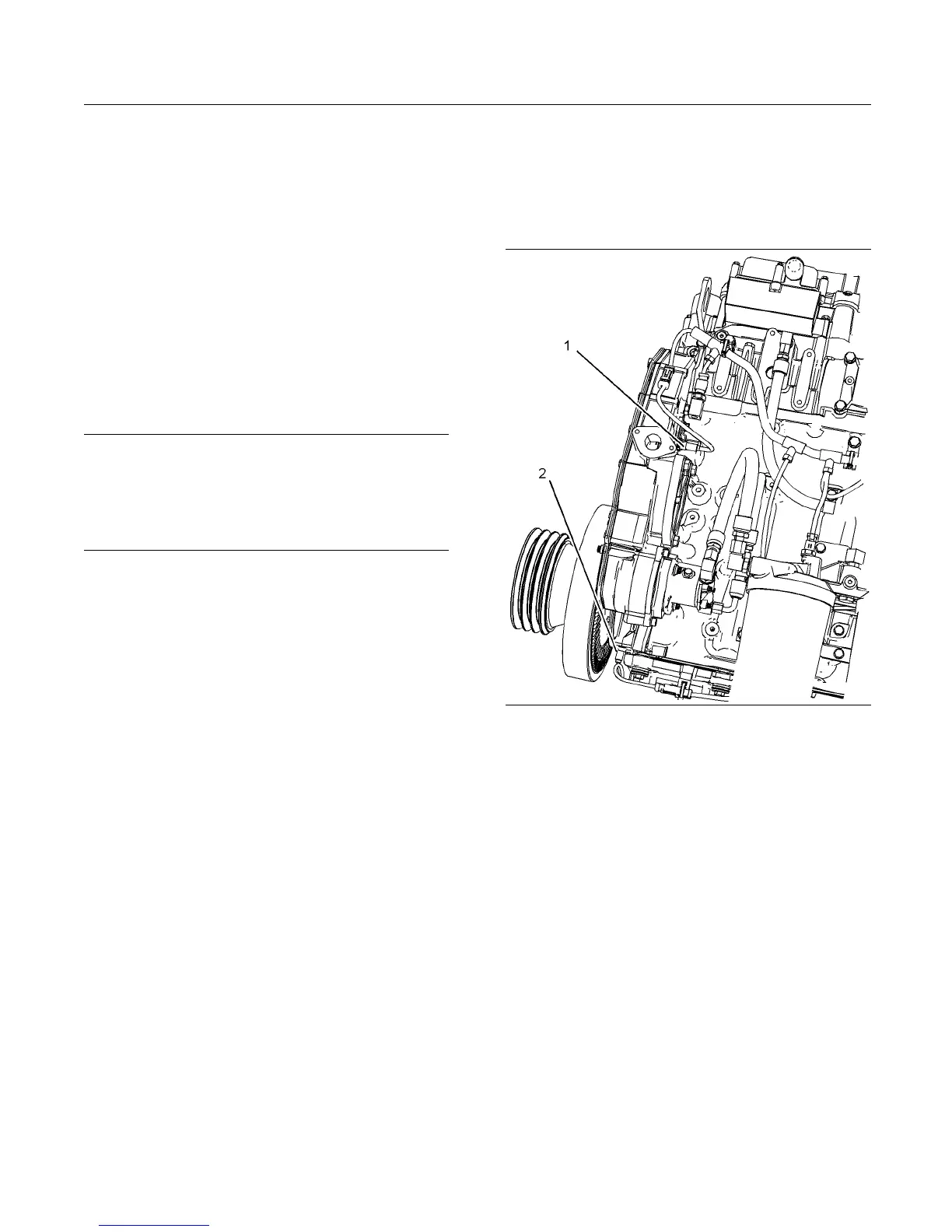

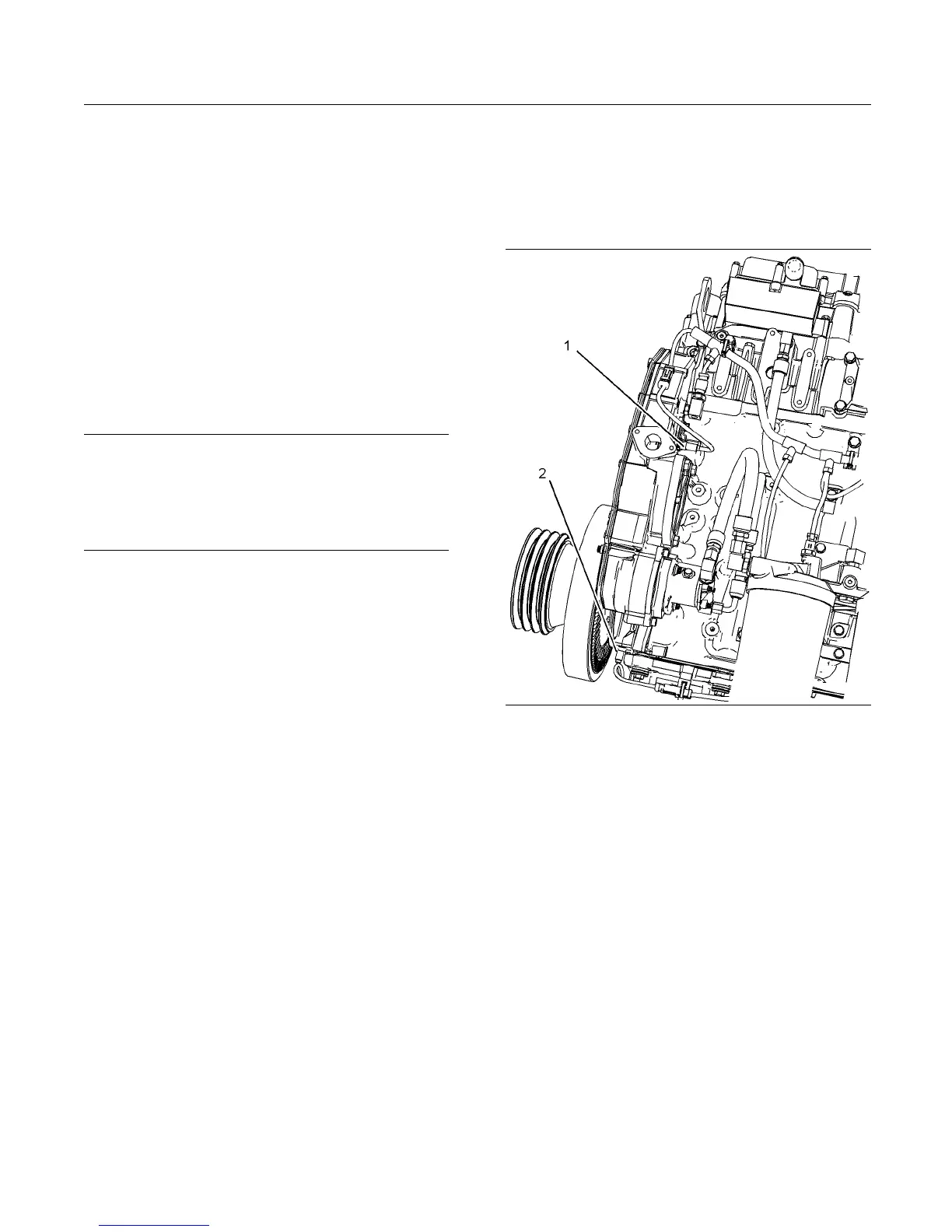

g01394162

Illustration 38

Left side view

(1) Secondary position sensor (Camshaft )

(2) Primary position sensor (Crankshaft)

1. Remove the sensors from the front housing.

Check the condition of the plastic end of the

sensors for wear and/or contaminants.

2. Clean the metal shavings and other debris from

the face of the sensors. Use the procedure in

the Service Manual in order to calibrate the

speed/timing sensors.

Refer to the Troubleshooting, “Calibration

Procedures” for more information on the speed/timing

sensors.

Loading...

Loading...