SEBU8337 57

Maintenance Section

Belts - Inspect/Adjust/Replace

5. Proceed with ne

cessary system repairs. Reverse

the steps in order to reconnect all of the cables.

i02784753

Belts - Inspec

t/Adjust/Rep lace

Inspection

Inspect the alternator belt and the fan drive belts for

wear and for cracking. Replace the belts if the belts

are not in goo

d condition.

Check the belt tension according to the information

in Systems Op

eration, Testing and Adjusting, “Belt

Tension Chart”.

Slippage of l

oose belts can reduce the efficiency

of the driven components. Vibration of loose belts

can cause unnecessary wear on the following

components

:

•

Belts

•

Pulleys

•

Bearings

If the belts are too tight, unnecessary stress is placed

on the compo

nents. This reduces the service life of

the components.

Replacement

For applic

ations that require multiple drive belts,

replace the drive belts in matched sets. Replacing

one drive belt of a matched set will cause the new

drive belt

to carry more load because the older drive

belts are stretched. The additional load on the new

drive belt could cause the new drive belt to fail.

Alternator Be lt Adjustment

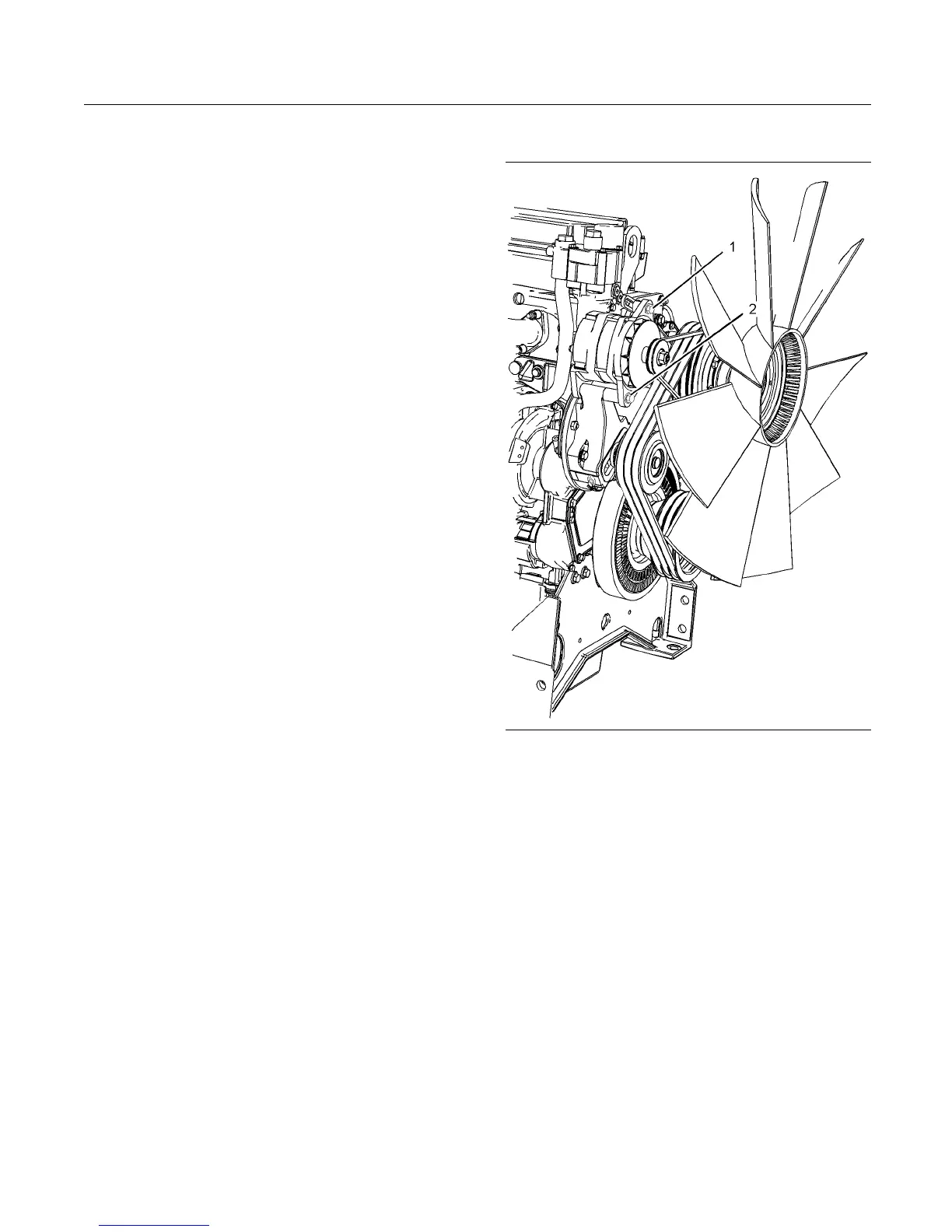

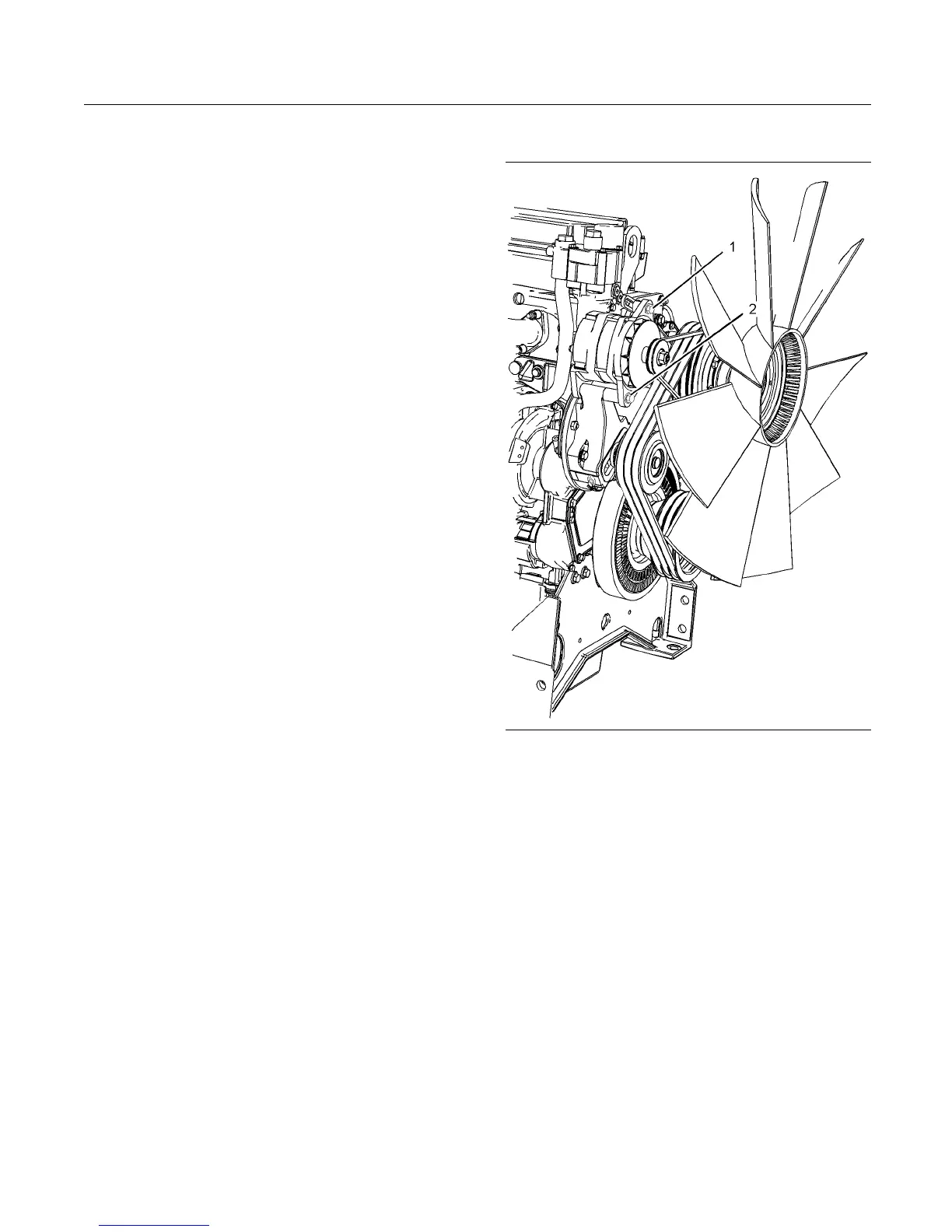

g01391209

Illustration 20

1. Remove the belt guard.

2. Loosen alternator pivot bolt (2) .

3. Loosen the setscrew for the adjustment link (1).

4. Move the assembly in order to increase or

decrease the belt tension. Refer to Systems

Operation, Testing and Adjusting, “Belt Tension

Chart”.

5. Tighten the setscrew for the adjustment link (1)

securely. Tighten alternator pivot bolt (2) securely.

6. Reinstall the belt guard.

If new alternator belts are installed, check the

tension of the alternator belt again after 10

minutes of engine operation at the rated rpm.

7. Remove the belt guard and check the belt tension.

When the correct belt tension is obtained, fitthe

belt guard.

Loading...

Loading...