MAINTENANCE PROCEDURES

30 4006/8 Diesel, May 1998

FAN BEARINGS AND BELTS

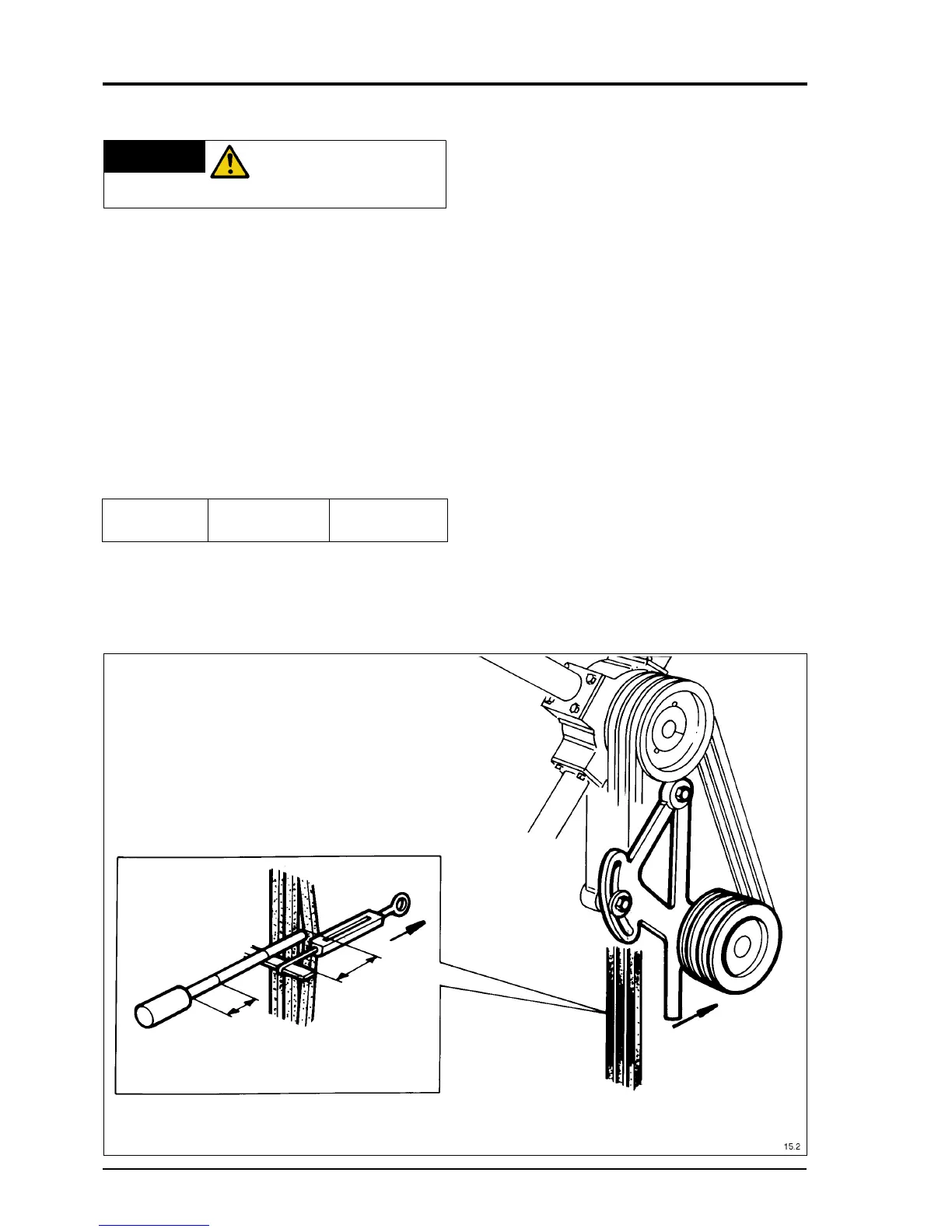

Remove the mesh guard around the fan

belts, grease the fan and jockey pulley

bearings Fig. 23 using high melting point

lithium based grease (e.g. Shell Alvania

R.A.)

Check the tension and condition of the fan

belts. Using a spring balance and rule, or a

belt tension indicator, check that the force

compares with the kgf (lbf) values shown

below for the correct belt deflection. See Fig.

23.

Fan belts if worn, should be replaced as a

complete, matching set. Individual belts

should NOT be replaced.

To adjust slacken the jockey pulley pivot and

adjuster bolts, and operate the jockey pulley

lever.

Moving the jockey pulley lever outwards will

tension the belts and inwards will slacken the

belts.

The correct tension is obtained by

measuring the deflection at the mid point

between the fan pulley and the crankshaft

pulley when the above force is applied.

To apply the force place a rule across the

outside width of the belts and attach spring

balance as shown Fig. 23 pull on the spring

balance until the required force is reached

and measure the belt deflection.

Adjust the position of the jockey pulley lever

until the force on the spring balance and the

belt deflection agree with the figures given

above.

Deflection

11 mm

kg Force

3-4.3

lb Force

6.67 - 9.47

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING.

WARNING

Fig. 23

force

deflection 11 mm

Loading...

Loading...