MAINTENANCE PROCEDURES

4006/8 Diesel, May 1998 31

When using a belt tension indicator position

the indicator on top of a belt at the mid centre

distance and apply a force at right angles to

the belt deflecting it to the point where the

lower marker is level with the top of the

adjacent belt. Read off the force value

indicated by the top edge of the upper

marker.

Having set the tension on the belts, tighten

the adjuster and pivot bolts.

Refit the fan belt guard.

NOTE: If the measured force falls within the

values given, the drive should be

satisfactory, if it is below the lower value

under tensioning is indicated.

A new drive should be tensioned to the

highervaluetoallowforthenormaldropin

tension during the running-in period.

After the drive has been running for 30

minutes, the tension should be checked and

re-adjusted to the higher value.

FAULT TRACING

a) Small cracks on V-Belt Side and Base

Generally caused by lack of belt tension

but excessive heat and/or chemical

fumes can also lead to similar failure.

b) V-Belt swelling and softening

Caused by excessive contamination by

oil, certain cutting fluids or rubber

solvents.

c) Whipping during running

Usually caused by incorrect tensioning

principally on long centre drives. If a

slightly higher (or lower) tension does

not cure the problem there may be a

critical vibration frequency in the system

which requires re-design or a banded

belt (2 belts banded together to make a

Wbelt).

CRANKCASE BREATHING

(SEE MAINTENANCE SCHEDULES)

CRANKCASE BREATHER ON EARLIER

ENGINES (RADIATOR COOLED)

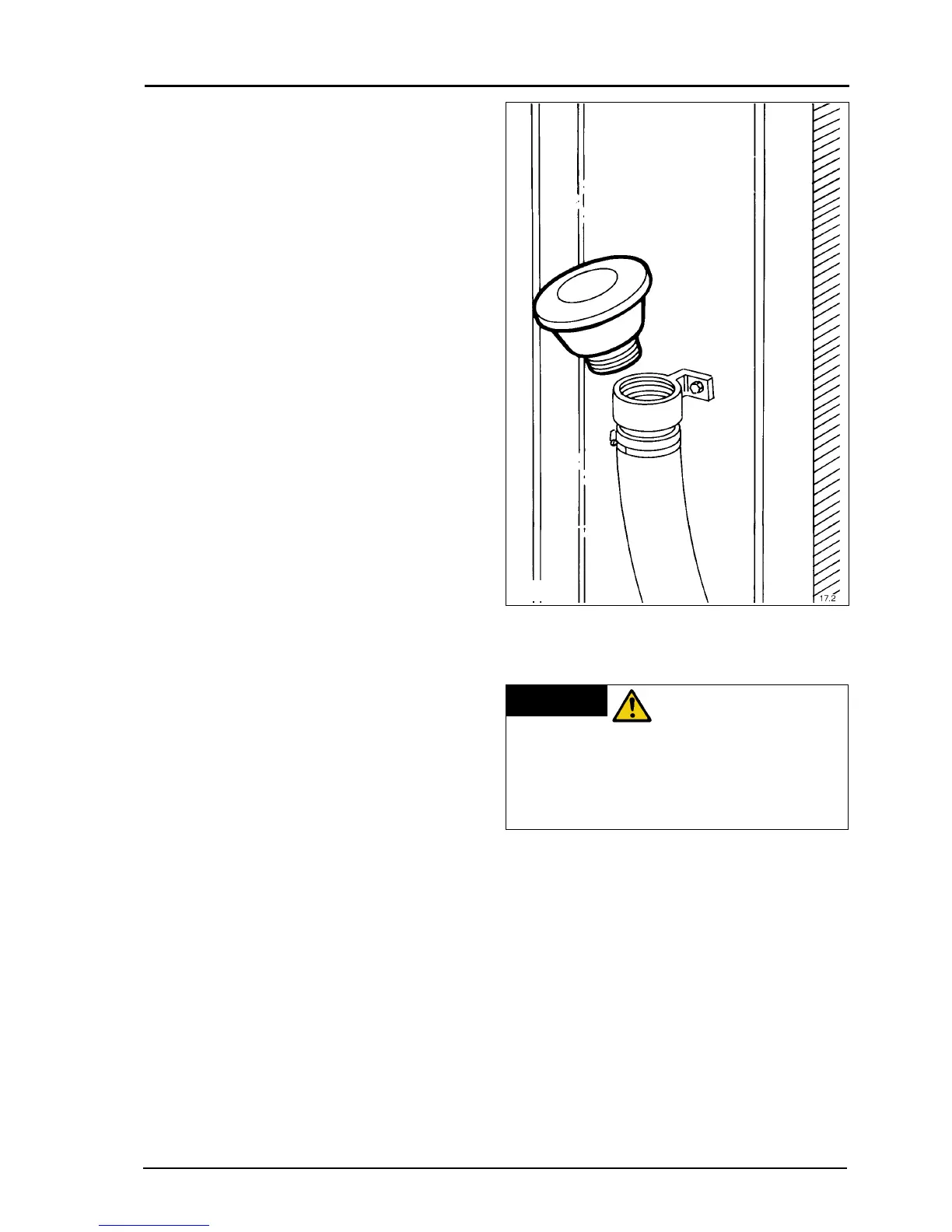

The crankcase breather is mounted on the

side of the radiator Fig. 24 and is connected

to an elbow mounted on the gearcase by a

flexible pipe Fig. 26.

Fig. 24

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING. WHEN

USING COMPRESSED AIR OR

CLEANING AGENTS ALWAYS WEAR

EYE PROTECTION, AND PROTECTIVE

GLOVES.

WARNING

Loading...

Loading...