12 - 2

Adjustment

-

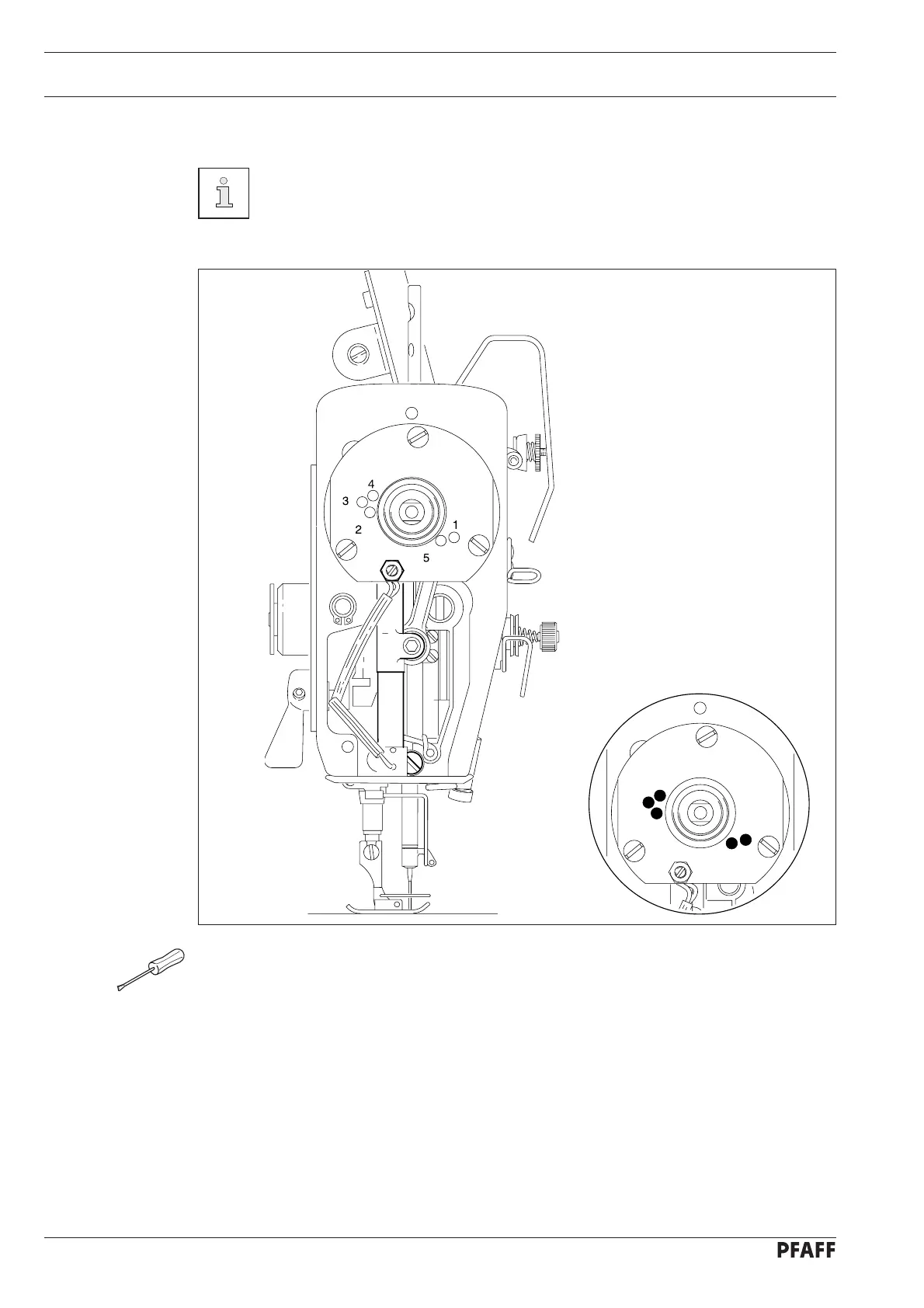

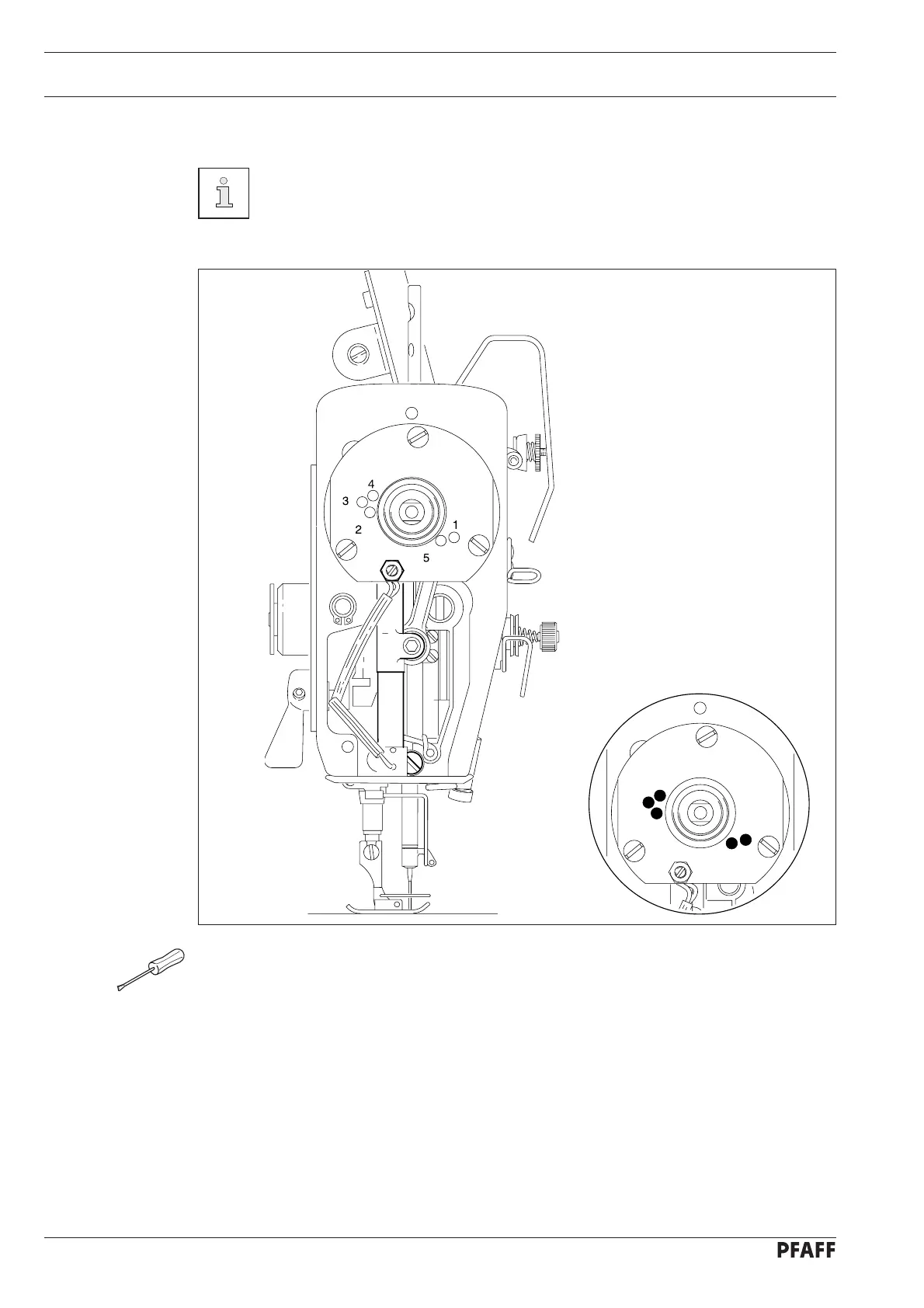

Fig. 12 - 01

81-016

4

2

5

1

3

● Turn the balance wheel until the needle bar has approximately reached the required

position.

● Place the 5 mm blocking pin in the appropriate hole and put pressure on it.

● Turn the balance wheel forwards and backwards a little until the blocking pin moves

into the slot in the crank behind the bearing plate, thus blocking the machine.

Hole 1 = 2.0 mm after the bottom dead center of the needle bar (2.0 past tdc)

Hole 2 = Top dead center of the needle bar (tdc)

Hole 3 = 0.25 mm after the top dead center of the needle bar (0.25 past bdc)

Hole 4 = 1.0 mm after the top dead center of the needle bar (1.0 mm past tdc)

Hole 5 = 4 mm after the bottom dead center of the needle bar (4.0 past bdc)

12.04 Check and adjustment aid

By blocking with holes 1 - 5 the required needle bar positions can be fixed

exactly.

Loading...

Loading...