12 - 40

Adjustment

1

+

-

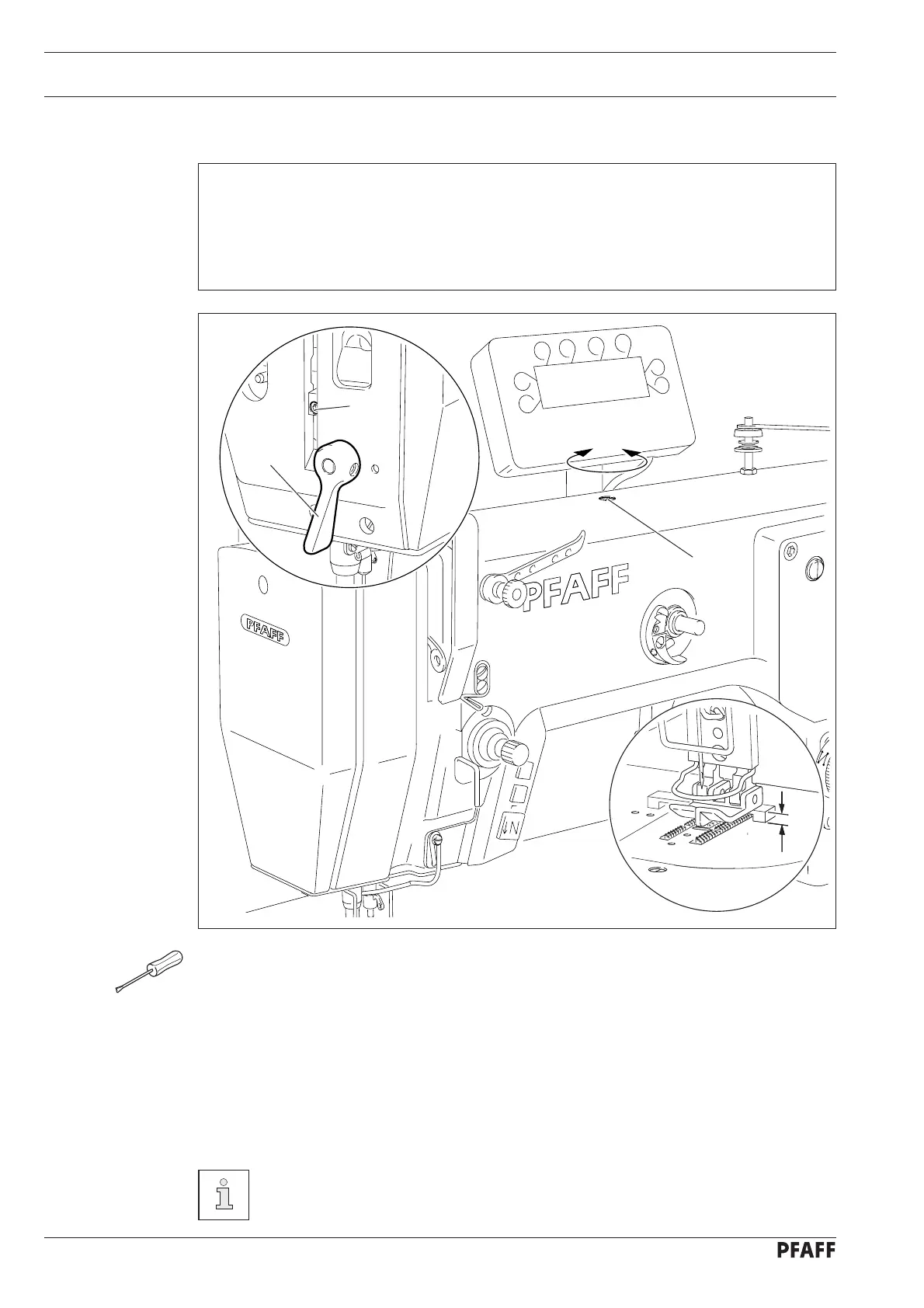

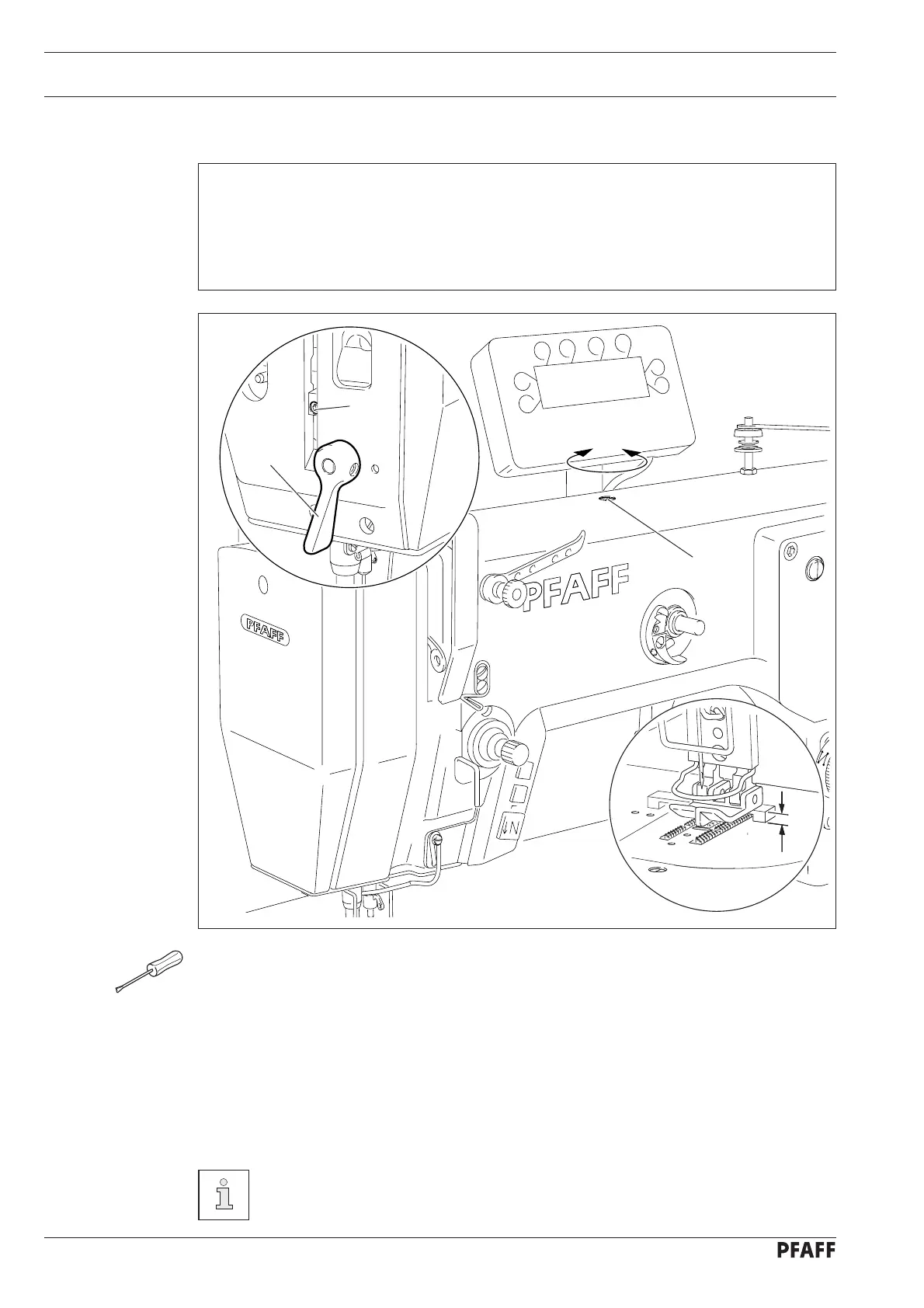

12.05.38 Presser foot to needle plate clearance / Presser foot pressure

Requirement

1. When the hand lever is raised, the needle should penetrate exactly in the "needle hole

centre" of the presser foot and the presser foot to needle plate clearance should be 5 mm.

2. Even at top sewing speed the material should be fed without problems. There should

be no pressure marks on the material.

● Set the zigzag stitch adjustment lever at "0" and the stitch position adjustment lever at "centre".

● Let the presser foot drop onto the needle plate and reduce the pressure on the presser

bar by turning screws 1.

● Place the feed dog adjustment gauge under the presser foot with the recess at the bottom.

● Loosen screw 2 and raise hand lever 3.

● Allow the needle to penetrate the needle hole and align the presser foot in accordance

with the requirement 1.

● Press the presser bar lifting piece down and tighten screw 2.

● Turn screw 1 in accordance with the requirement 2.

The presser foot pressure (screw 1) can be increased (+) or reduced (-) as

required.

81-036

2

3

Fig. 12 - 39

5 mm

Loading...

Loading...