085 408 164 9

3 Scope of delivery and options

3.1 Scope of delivery

The Scope of delivery includes:

• coolingunit(withconnectionfordoorcontactswitch)

• Enclosedpackage(amongotherthingssealingprole,faste-

ningmaterial,electricalplug-typeconnectors)

• specialaccessories,ifapplicable.

3.2 Options

The following parts may be ordered separately:

– Coverwithfront-endlter;

– further options on request or in accordance with the catalogue.

4 General Information

• OlddevicescanbeproperlydisposedofbyPfannenberg.They

must be sent to one of our works shipment/postage paid.

• AllcoolingunitsproducedbyPfannenberg are free from

– siliconecompounds,

– PCB,

– PCT,

– asbestos,

– formaldehyde,

– cadmium,

– substances impairing wetting.

• Everycoolingunitis checked to ensure that it is tight accor-

ding totheprovisionsofUVV-BGV

D4(Germanregulationscovering accidentprevention).

• Priortodeliverytheelectricalsafetyofeverycoolingunitis

factory tested. This means that,

inaccordancewithUVV-BGVA2,§5(4),theoperatingcompanyis

released from the obligation to arrange for a test of the electrical

part of the cooling unit before initial start of operation.

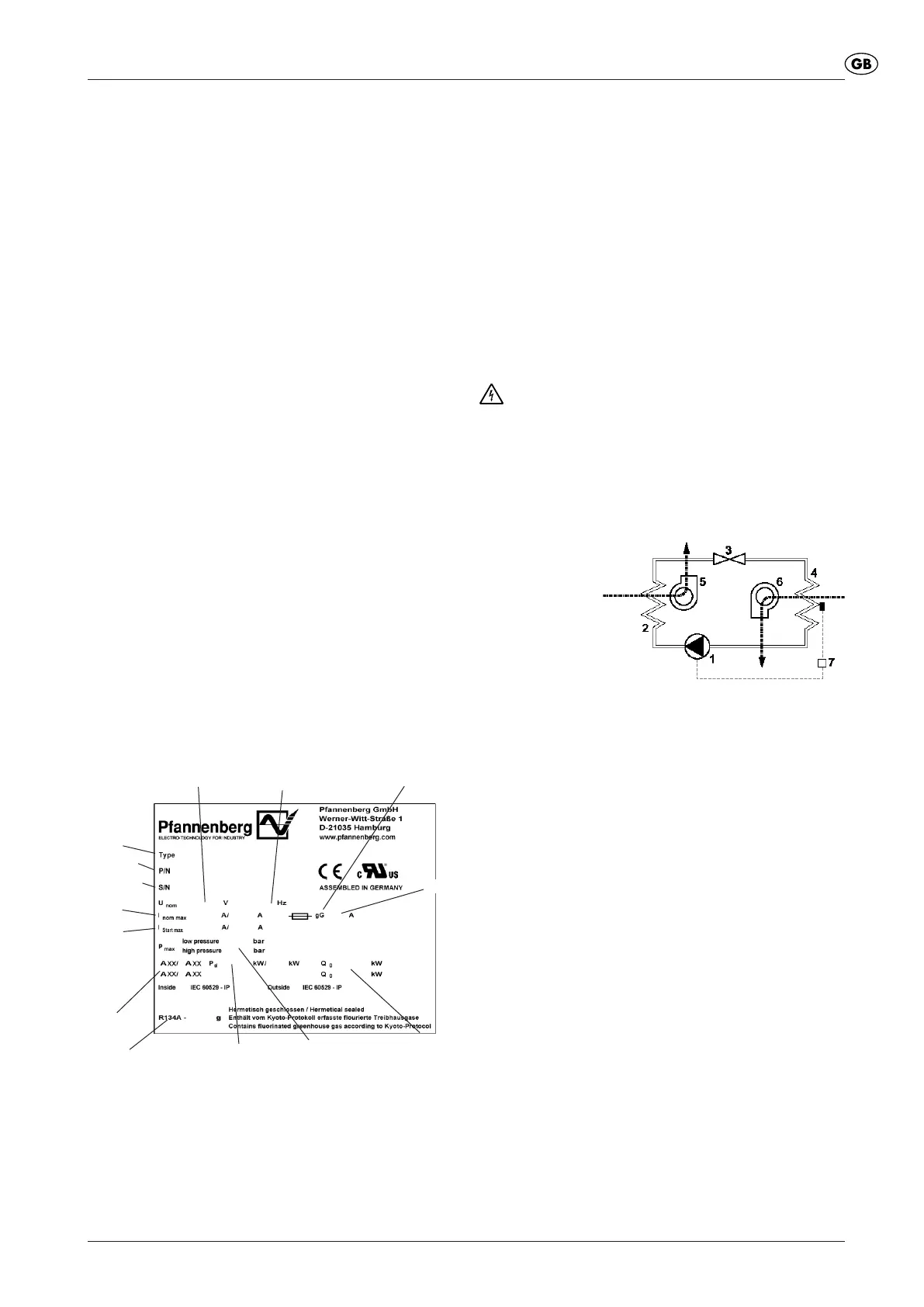

5 ID Plate and Technical Data

For installation and maintenance, note the data on the ID plate; it is

to be found on the back of the cooling unit casing

The technical details applicable to the cooling unit are in the sup-

plement.

6 Safety

Cooling units produced by Pfannenberg are designed for dissipa-

tingheatfromswitchcabinets(IP54).Duringeachcoolingprocess

condensate can be produced. The cooling unit is only suitable for

stationary operation.

The cooling unit may only be used under the ambient conditions

speciedontheenclosedsheet.

Thecoolingunitistoalargemeasuremaintenance-free(seeSec-

tion11).

Every other use is considered as non-authorized use making any

warranty null and void.

The electrical equipment must be regularly checked. Any faults

such as loose connections or scorched cables must be removed

immediately.

Work on the cooling system and on electrical components may only

be carried out by authorized specialist personnel.

Compliance with applicable safety and environmental regulations

is mandatory.

Hazard!

Isolate the cooling unit from the mains before carrying out

any cleaning or maintenance operations.

Only original spare parts may be used.

7 Function

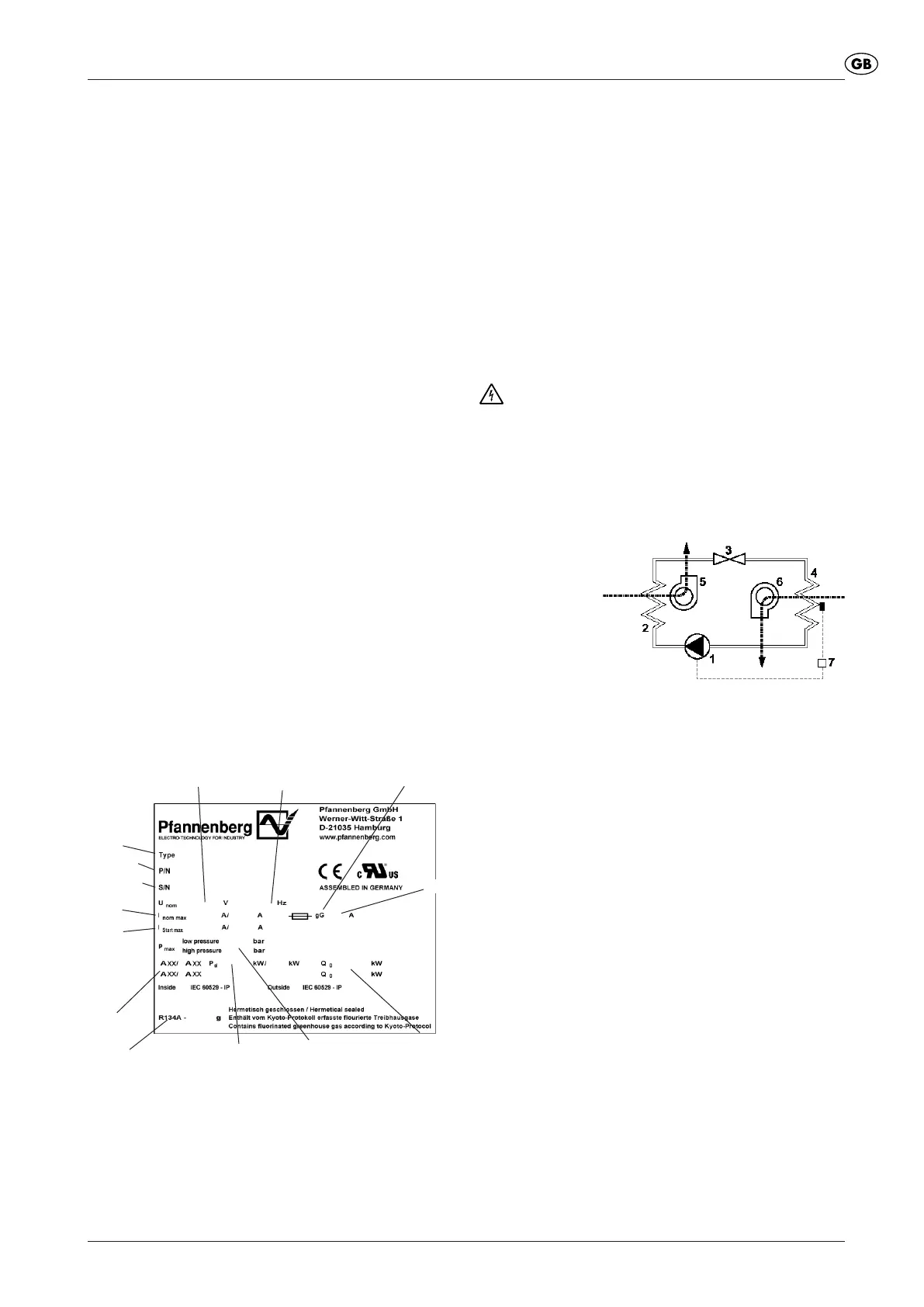

7.1 Principles of function

1 Compressor

2 Heat exchanger

(condenser)

3 Expansion valve

4 Heat exchanger

(evaporator)

5 fan, exterior circulation

6 fan, inner circulation

7 Electronic control system with temperature sensor

Thecompressor(1)compressestherefrigerantuntilhighpressure

is achieved. During this process temperature increases. In the con-

denser(2)heatisdissipatedtoambientair,thecoolantbecoming

liquid.Thecondenserfan(5)ofthecondensatortakesambientair

in through the condenser, then it releases the air.

Intheexpansionvalve(3)thepressureofthecoolantdrops.Inthe

evaporator(4)thecoolantabsorbsheatfromtheairintheswitch

cabinet and evaporates. Thus, the air in the switch cabinet cools

down. At the same time the air inside the switch cabinet is being

dehumidied.Theevaporatorfan(6)suckstheairoutoftheswitch

cabinetviatheevaporator,thecooledairowsbacktotheswitch

cabinet.

The cooling unit is electronically controlled. For that purpose a

temperature sensor records the temperature of the air inside the

switchcabinet(7).

The refrigerant is not detrimental to the ozonosphere; it is hardly

combustible.

7.2 Condensate

During cooling on the evaporator the moisture removed from the air is

collected as condensate. In order to avoid any damage to the switch

cabinet and the cooling unit, the condensate must be discharged.

The condensate is discharged in the following way:

• Incaseofnormalcondensatedrainageareservoircollectsthe

condensate which is then drained by means of a hose.

Always ensure that the condensate is drained properly (safety-

drainage).

Excessive condensation can occur if, for example, the switch cabinet

is not sealed or if the internal temperature of the switch cabinet is

frequently below the dew point.

unit type

refrigerant

nominal voltage

pressure of

refrigerant

frequency

serial number

type of fuse

electrical

energy

exterior/interior

conditions

cooling

capacity

starting

current

nominal current

part number

fuse

Loading...

Loading...