THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 1

Feb 19/04

5L7

95-00-00

GENERAL

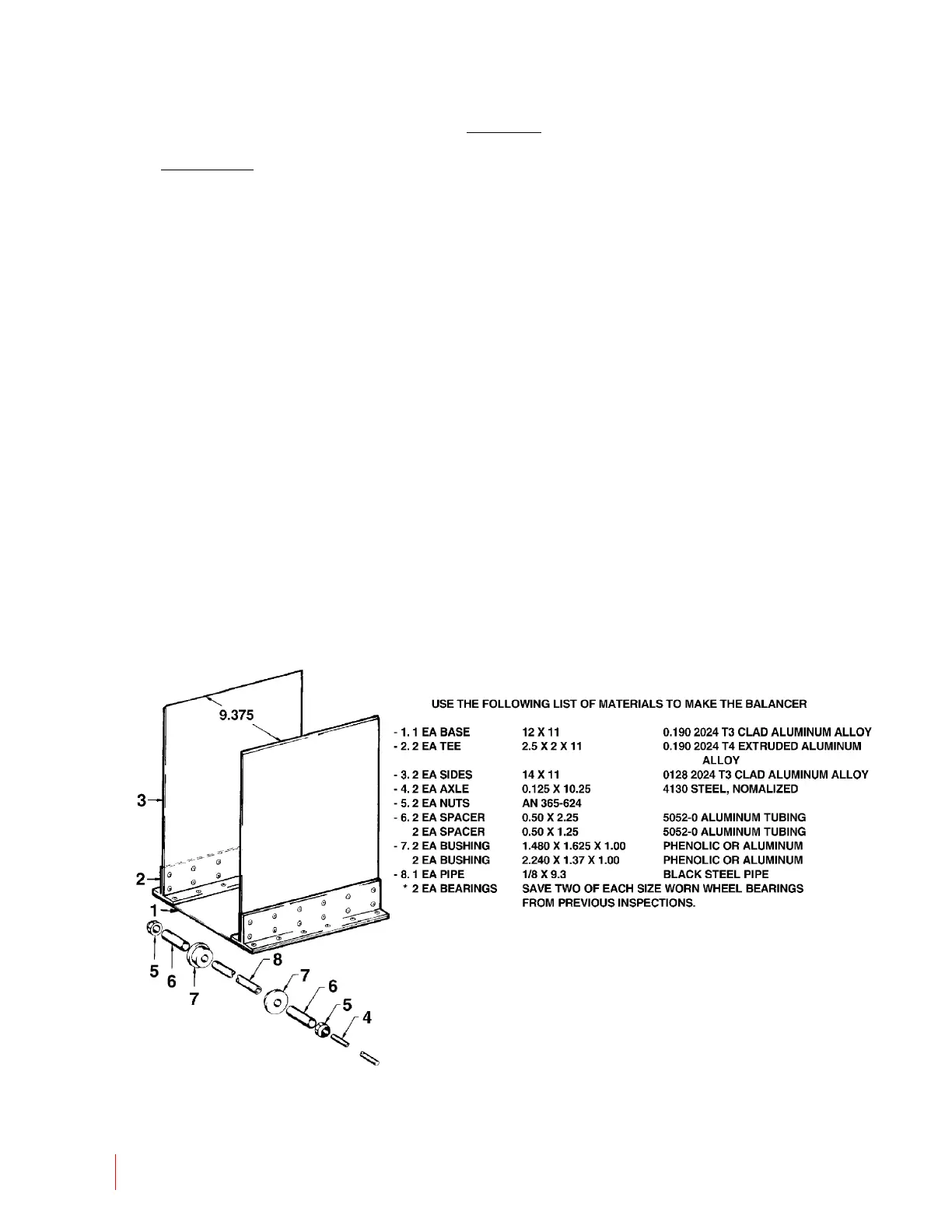

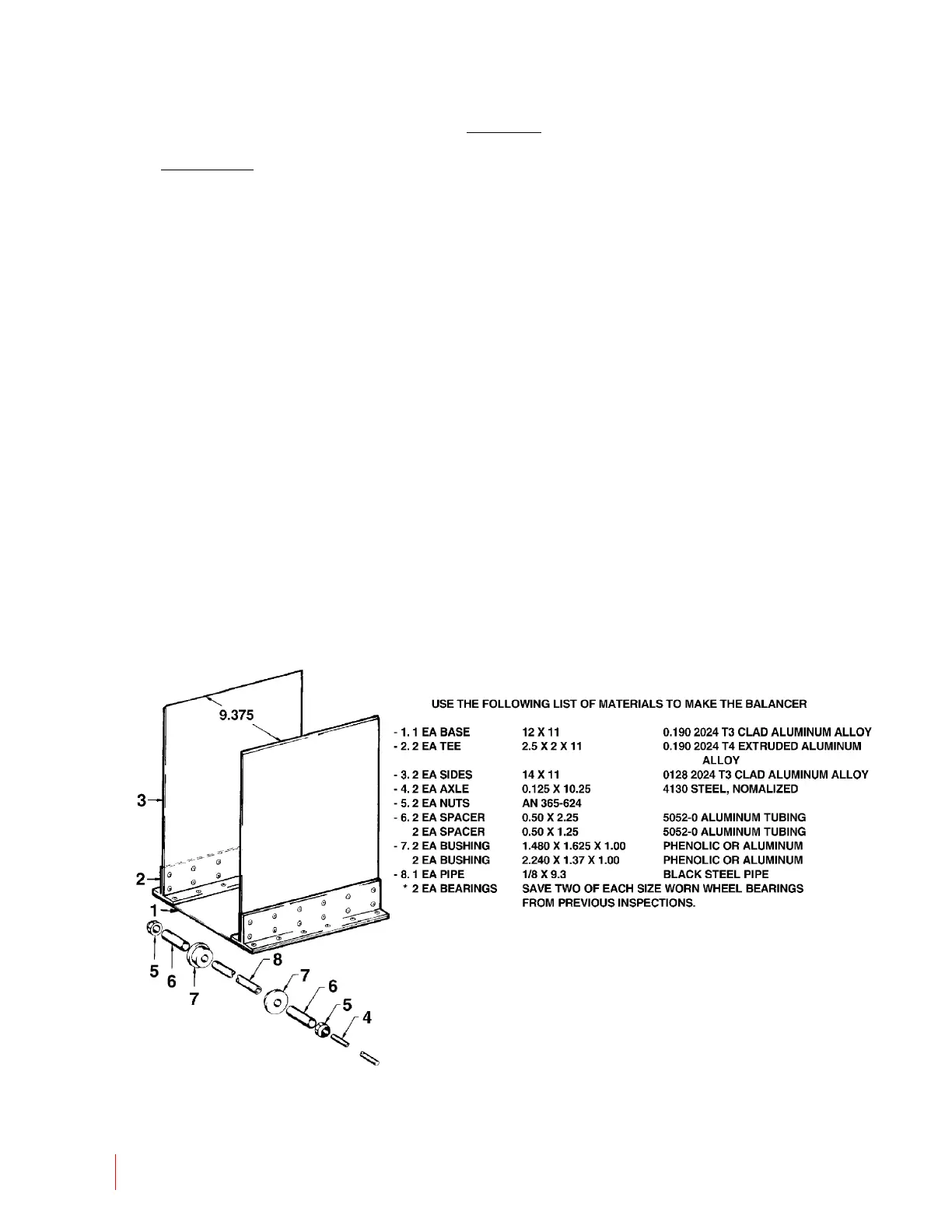

1. Tire Balancer (See Figure 1.)

A useful tire balancing fixture can be built as follows:

A. Chamfer top edges of -3 sides, leaving 1/16 inch flat on top of the inboard edge. Rivet -2 tee’s to -3

sides using AN 470-AD5 rivets, with 2 inch spacing, and using AN 426-AD5 rivets ( 2 inch center to

center ) to secure -2 tee’s to -1 base. If tee extrusion is unavailable, heavy angle extrusion could be

used. -3 sides must be vertical.

B. The -4 axle must slide through the -8 pipe, the -5 nuts are made by reaming the existing threads in

the AN 365-624 nuts with an R drill, then tapping them with a 1/8-27 pipe tap.

C. The -6 spacers were made from 1/2 inch aluminum tubing, the two lengths of spacers are suitable

for balancing most any aircraft wheel.

D. The -7 bushings may be made from one inch phenolic or aluminum using a 1-1/2 inch hole saw to

cut out the smaller bushing and a 1-3/4 hole saw to cut out the larger. By inserting a 1/4 inch long

threaded bolt through the pilot hole and securing with a washer and nut, a drill press and file may

be used to make the off-set on the bushing. The turned-down part should just slide inside the

bearing race and then ream the pilot hole to slide over the -8 pipe threads.

E. The -8 pipe was made from a piece of 1/8 inch black pipe and threaded with a 1/8-27 pipe die, this

will be thread 3 inches in from each end of the pipe.

Tire Balancing Fixture

Figure 1

Loading...

Loading...