Installation, use and maintenance

M0546

46 /6 0

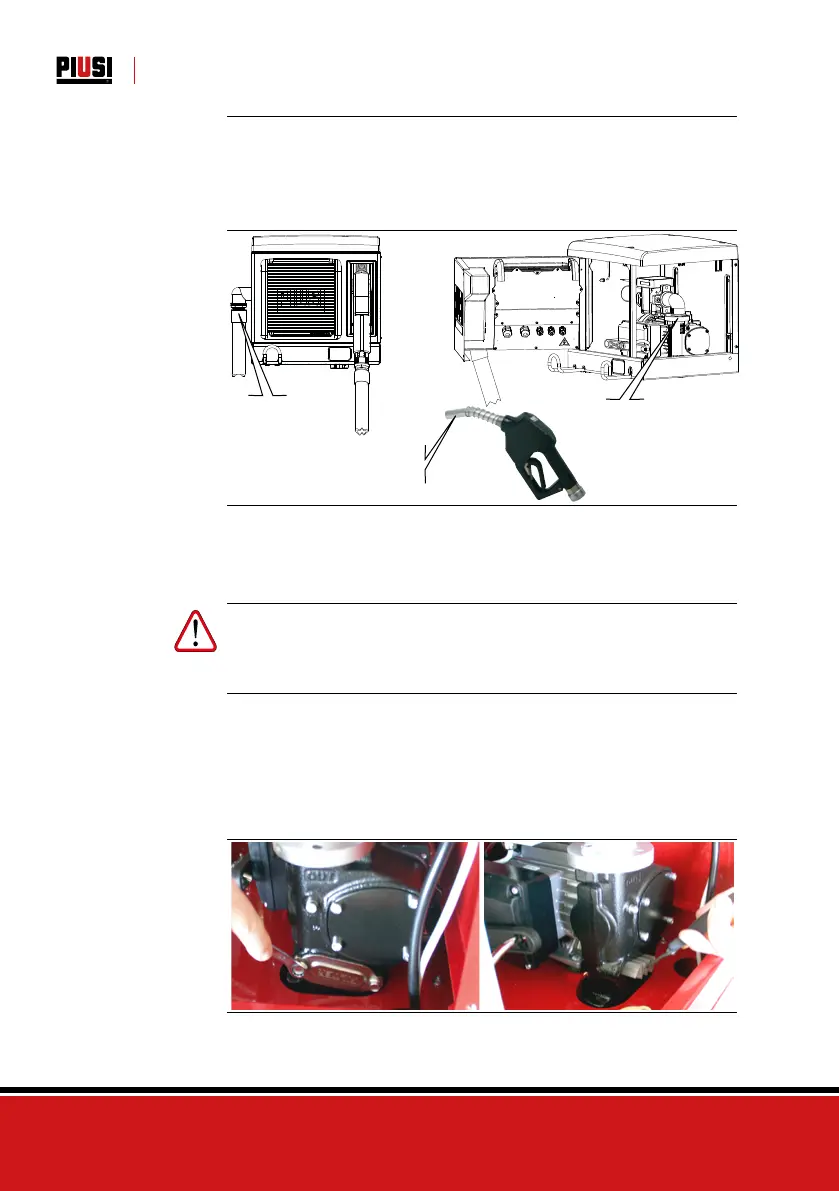

DISPENSING

HOSE AND

NOZZLE

Keep the dispensing hose and nozzle clean, checking in particular that:

- The hose is intact and not damaged by the transit of vehicles

- Threaded connections are tight and do not show any leaks

- Swivel connections (at the station exit and on the nozzle) rotate freely and

do not show any leaks

- The hole in the automatic stop probe at the end of the nozzle hose (spout)

is always clean.

SWIVEL

CONNECTIONS

FLANGED

CONNECTIONS

AUTOMATIC

STOP PROBE

HOLE

(SPOUT)

FILTERS CUBE B.SMART is equipped with some filters, having different functions.

Checking and cleaning (or replacing) each of them is of utmost importance

to ensure:

- Protection of the various station components (pulser, pump, nozzle)

- Maintaining station performance over time (maximum flow rate)

- The protection of the engines in which the diesel dispensed is used

IMPORTANT

Dirty or partially clogged filters can increase pressure drop so that the

maximum flow rate dispensed by the pump is significantly reduced. Dirty

or clogged filters at the pump suction also generate a significant vacuum

increase in the suction which can also cause a significant increase in the

noise level of the pump.

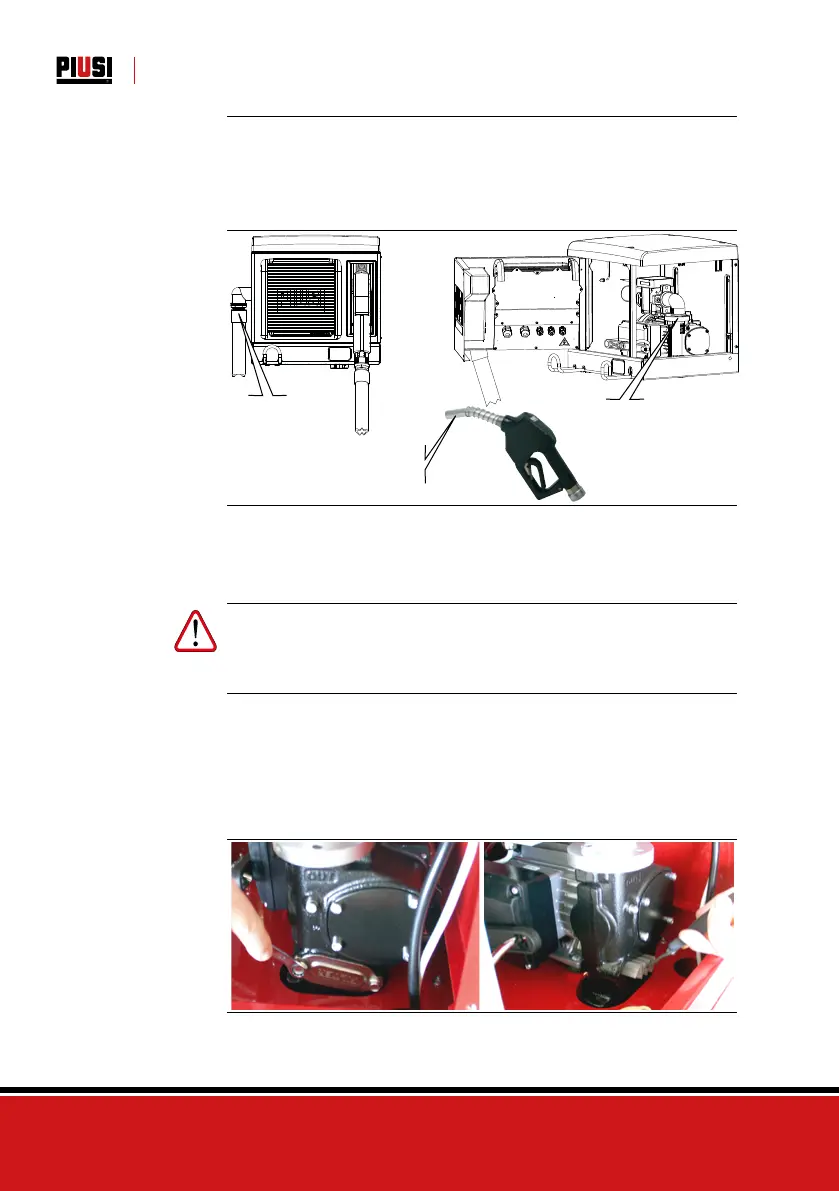

PUMP FILTER

(ONLY FOR AC

VERSIONS)

It is installed in the pump body as standard equipment of the PANTHER

pump. To check and clean it:

1 - Loosen the two screws of the filter cover and remove it from the body.

2 - Pull the mesh filter out, using pliers.

3 - If it is necessary to clean it, wash it and blow it.

4 - Carefully replace the filter in the housing of the pump body, taking care

that it does not protrude from the housing of the cover.

5 - Check and clean the flat seal, re-position the cover and tighten the

screws.

Loading...

Loading...