6.13

CLUTCHING

6

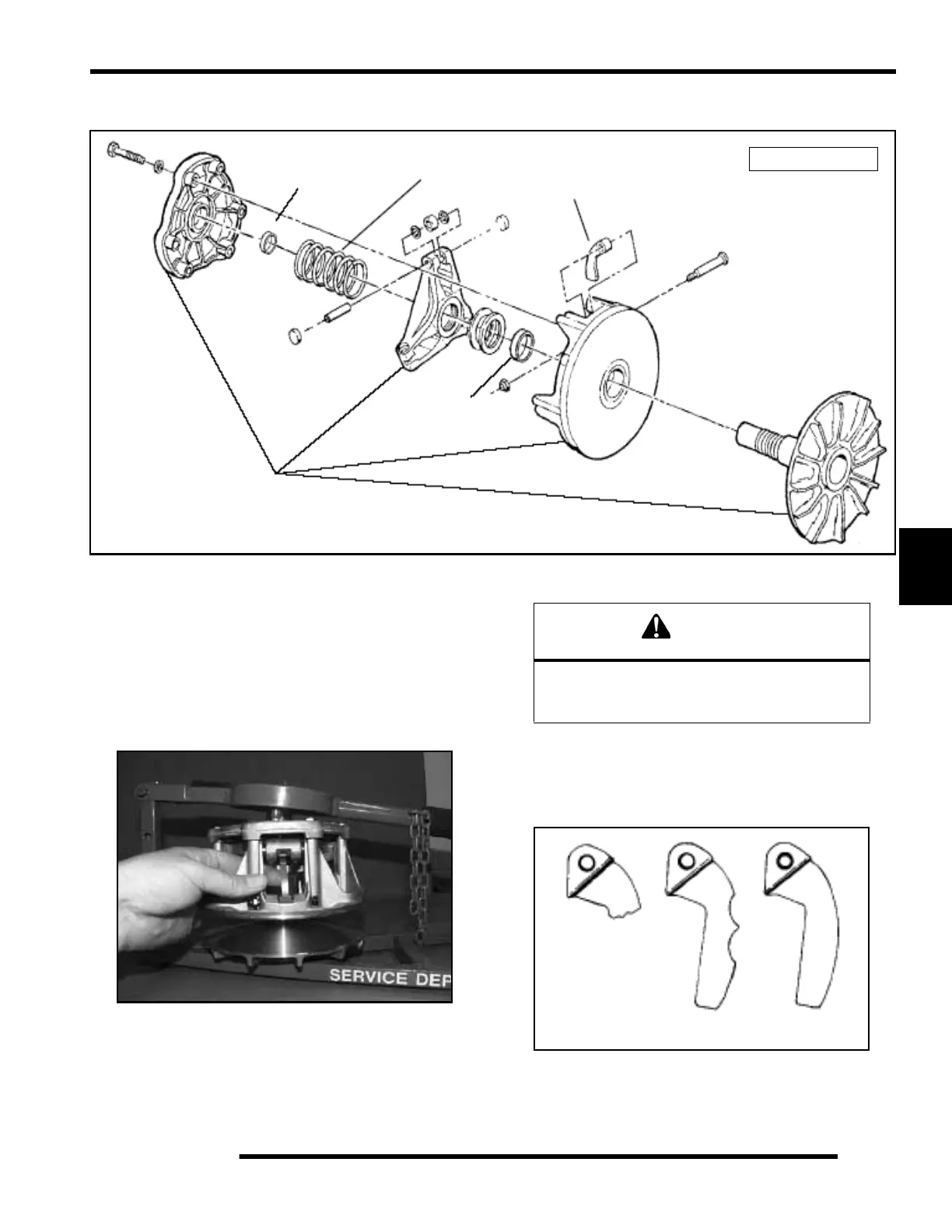

Exploded View

Clutch Inspection

All PVT system maintenance repairs must be performed only by

an authorized Polaris service technician who has attended a

Polaris sponsored service training seminar and understands the

proper procedures as outlined in this manual. Because of the

critical nature and precision balance incorporated into the PVT

system, it is absolutely essential that no attempt at disassembly

or repair be made without factory authorized special tools and

service procedures.

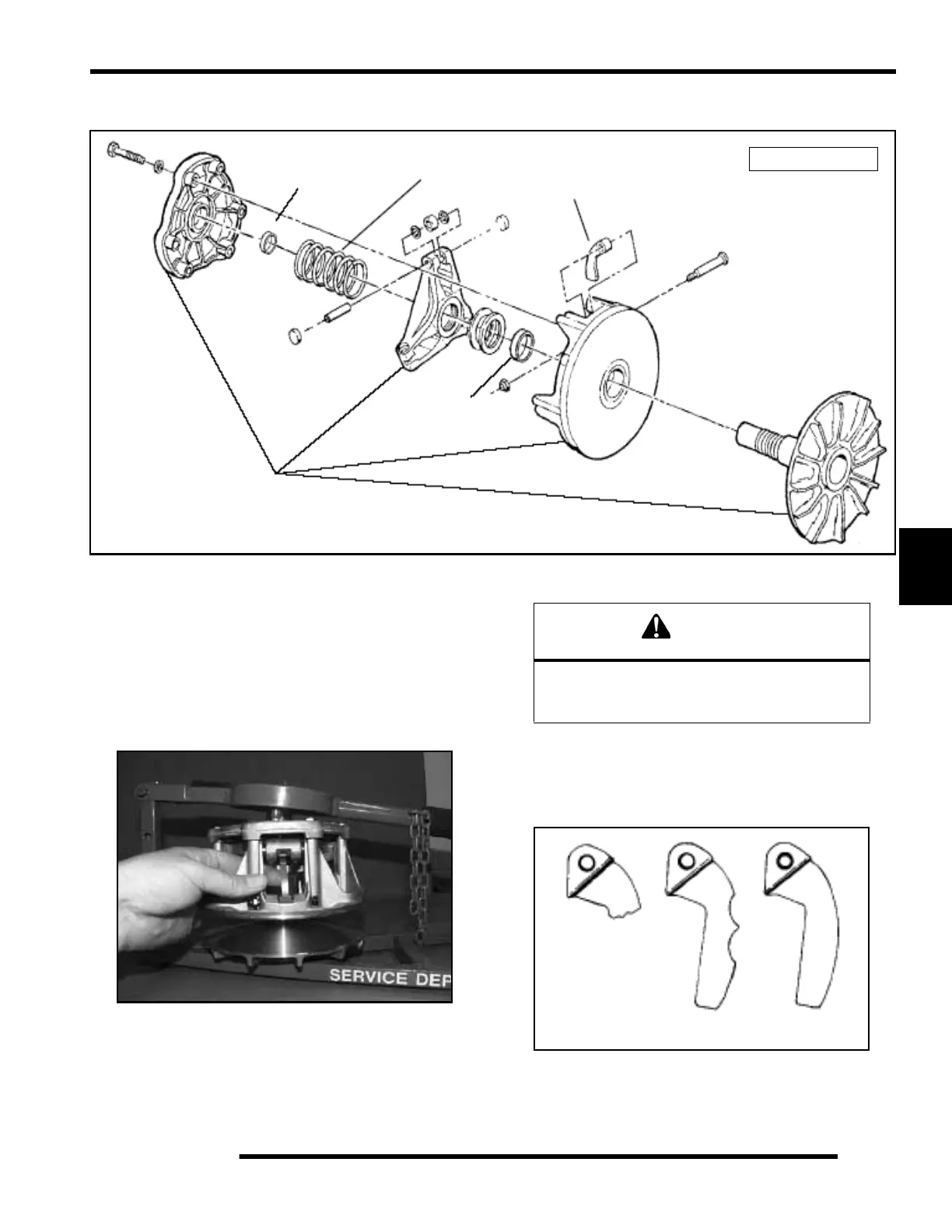

1. Remove shift weight bolts and weights. Inspect as shown.

The contact surface of the weight should be smooth and

free of dents or gall marks. Inspect the weight pivot bore

and pivot bolts for wear or galling. If weights or bolts are

worn or broken, replace in sets of three with new bolts.

NOTE: A damaged shift weight is usually caused by

a damaged or stuck roller in the spider assembly.

See “Roller, Pin and Thrust Washer Inspection”.

Tef lo n

TM

coated

brass bushing

Shift Weight

Drive Clutch

Spring

Mark with permanent

marker before disassembly

DRIVE CLUTCH

Tefl o n

TM

coated

brass bushing

WARNING

The clutch assembly is a precisely balanced

unit. Never replace parts with used parts from

another clutch assembly.

Broken Worn Good

Loading...

Loading...