9.18

BRAKES

FRONT BRAKE DISC

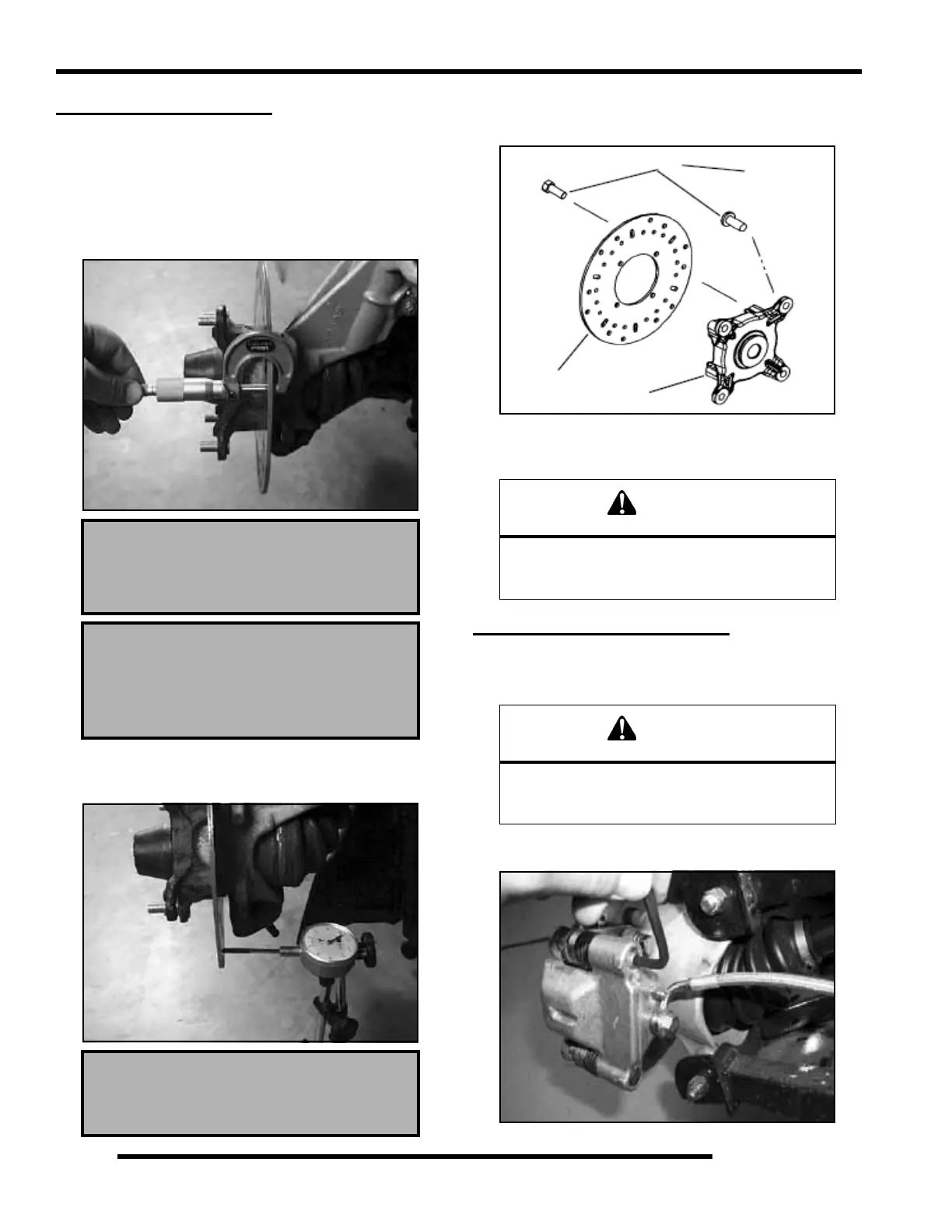

Disc Inspection

1. Visually inspect the brake disc for nicks, scratches, or

damage.

2. Measure the disc thickness at 8 different points around the

pad contact surface using a 0-1"micrometer. Replace disc

if worn beyond service limit.

3. Mount dial indicator as shown to measure disc runout.

Slowly rotate the disc and read total runout on the dial

indicator. Replace the disc if runout exceeds specifications.

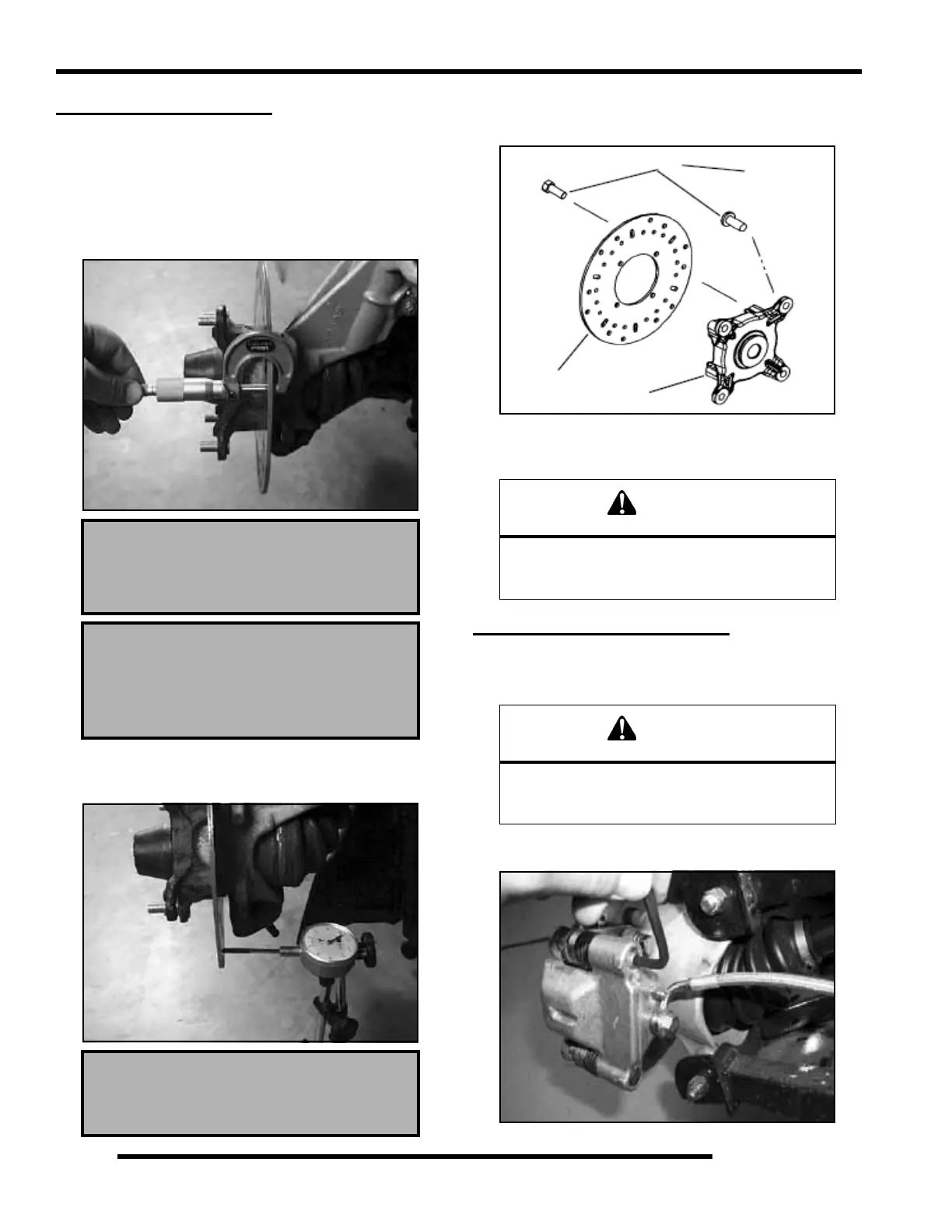

Disc Removal / Replacement

1. Remove bolts and disc.

2. Clean mating surface of disc and hub.

3. Install disc on hub.

4. Install new bolts and tighten to 18 ft.lbs. (24 Nm).

REAR BRAKE PAD (4X4)

Pad Removal

1. Elevate and support rear of machine.

2. Remove the rear wheel. Loosen pad adjuster screw 2-3

turns.

Brake Disc Thickness

New .150-.165” (3.81 - 4.19 mm)

Service Limit .140”/3.56 mm

Brake Disc Thickness Variance

Service Limit .002” (.051 mm)

difference between measurements

Brake Disc Runout

Service Limit .010” (.254 mm)

CAUTION

Always use new brake disc mounting bolts. The

bolts have a pre-applied locking agent which is

destroyed upon removal.

CAUTION

Use care when supporting vehicle so that it does

not tip or fall. Severe injury may occur

if machine tips or falls.

Bolts

18 ft. lbs.

(24 Nm)

Disc

Hub

Loading...

Loading...