5.4

Engine Systems

9923396 - 2007-2012 EDGE/Widetrak LX Service Manual

©2011 Polaris Sales Inc.

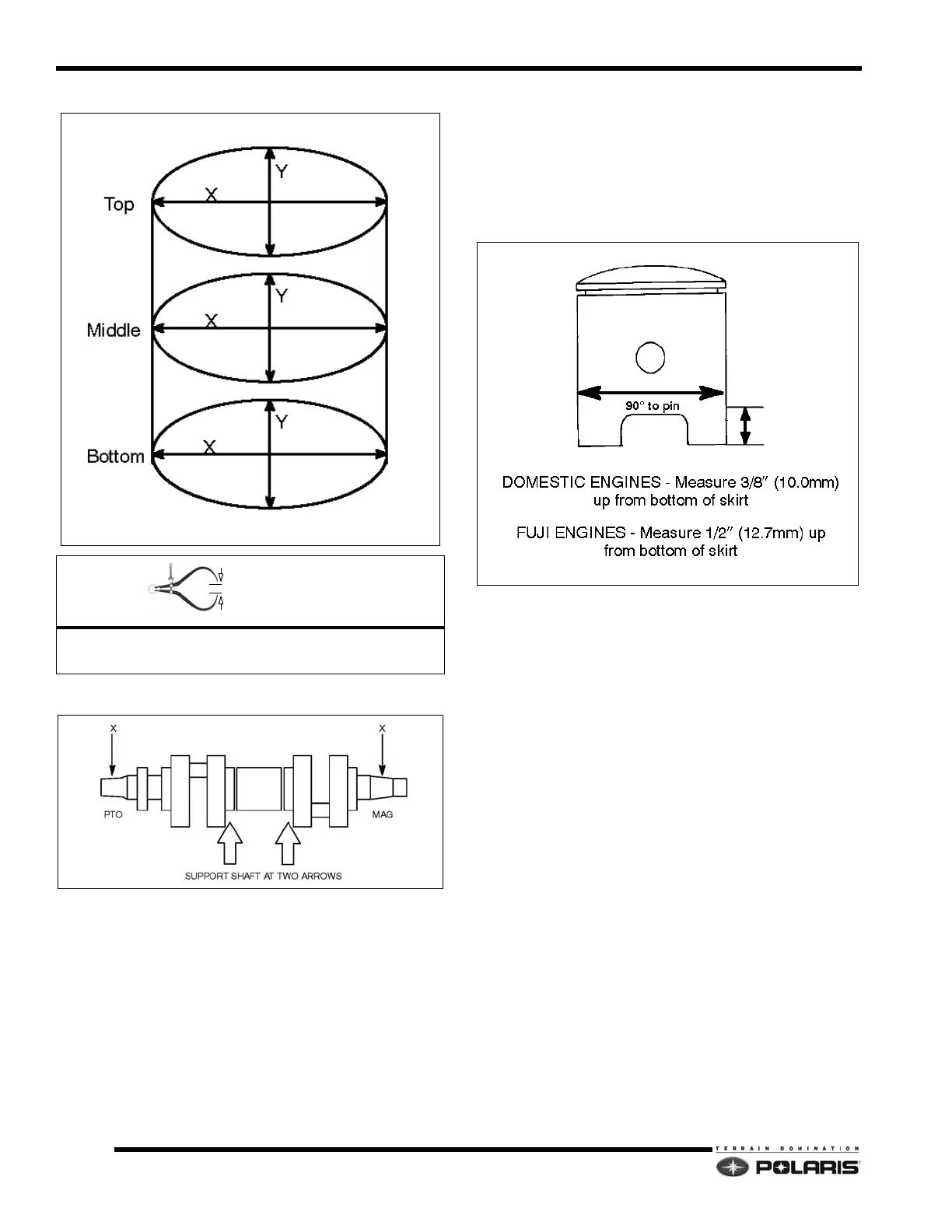

Crankshaft Runout Inspection

1. Support the crankshaft in a set of “V” blocks as shown.

2. Use a dial indicator to measure the runout at the

following locations:

• PTO end = First taper after bearing flat.

• MAG end = 1/2" from bearing flat.

3. Runout deflection cannot exceed .0025" (.07mm).

4. If the runout deflection exceeds the maximum

specification, crankshaft trueing may correct the

deflection.

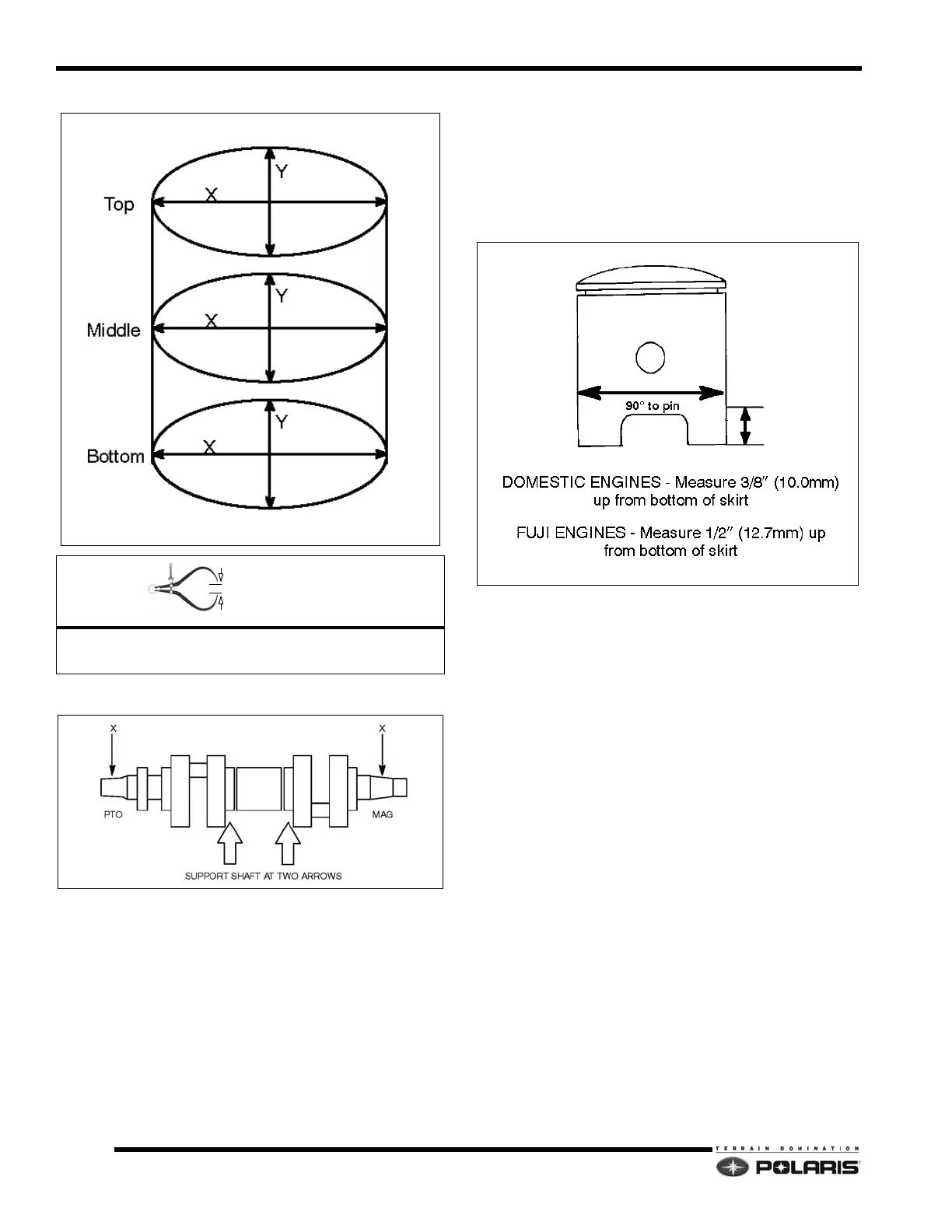

Piston Inspection

Check piston for scoring or cracks in piston crown or pin

area. Excessive carbon buildup below the ring lands is an

indication of piston, ring or cylinder wear. On Fuji engines,

measure piston outside diameter at a point that is 1/2"

(12.7mm) up form the bottom of the skirt at a 90° angle to

the direction of the piston pin.

Subtract this measurement from the minimum cylinder

measurement (90° to the pin). If clearance exceeds the

service limit, the cylinder should be re-bored (replaced if

Nicasil-lined) and new pistons and rings installed.

Taper Limit = .002" (.051mm)

Out-of-Round Limit = .002" (.051mm)

Loading...

Loading...