6.15

Drive and Brake Systems

6

9923396 - 2007-2012 EDGE/Widetrak LX Service Manual

©2011 Polaris Sales Inc.

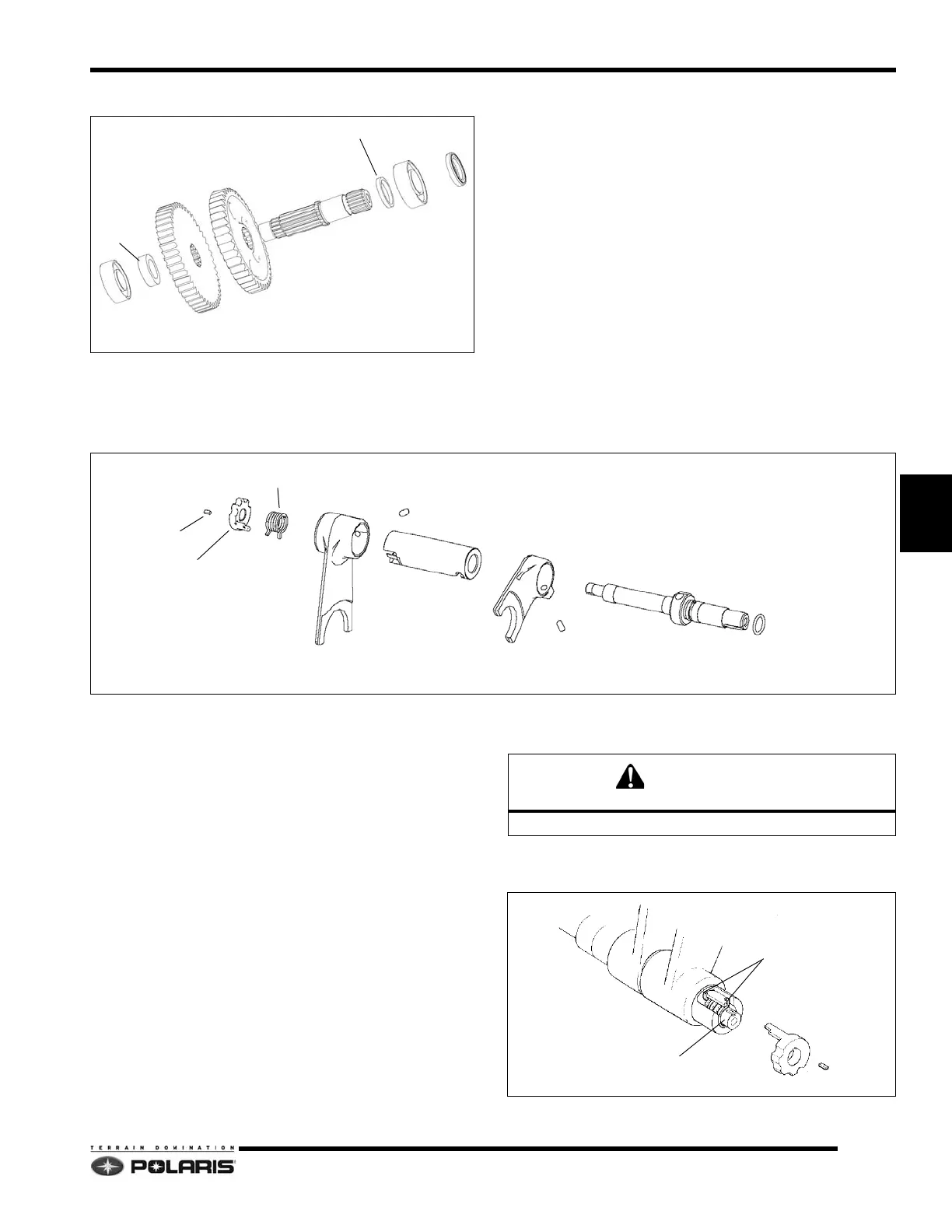

Output Shaft Inspection

1. Remove bearings using bearing splitter and press.

2. Inspect bearings to ensure they roll smoothly with no

flat spots.

3. Discard seal and spacers. Replace with new parts.

4. Inspect gear and spline teeth for rounded edges and/

or abnormal wear. Replace parts as required.

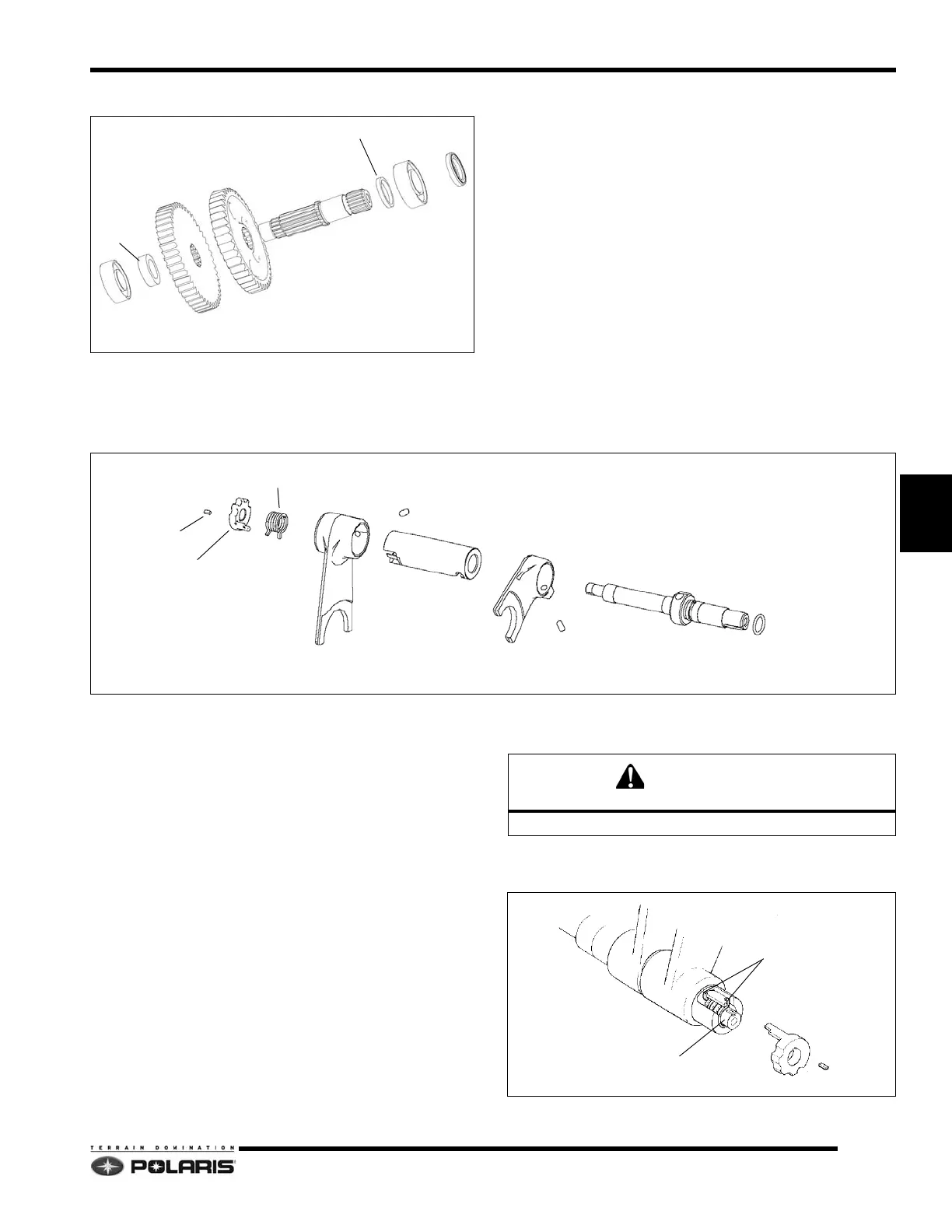

Shift Drum Inspection

1. Remove the detent cam, spring and shaft. Discard o-

ring and replace with new part.

2. Check condition of key-way and key. Inspect

indicator, spring legs and detent areas for wear.

Replace parts as required.

3. Shift forks can be removed from shift drum by moving

shift fork to the end of it’s travel and aligning with the

corresponding hole in the shift drum. Press dowel pins

into inner shift drum. Discard pins and replace with

new.

4. Inspect shift forks for abnormal wear and tear.

Replace if unevenly worn.

5. Inspect shift drum tracks for damage. Replace drum

if any damage is found.

6. When installing shift forks, press dowel pins up to

.100

(2.5mm) below top of bore. Verify pins do not

bottom-out on shift groove.

7. Locate spring in retainer slot as shown in illustration.

Arm of shift index must be positioned between both

ends of spring.

NOTE: The spring must be pre-loaded upon

installation. Refer to illustration.

BEARING

SPACER

47T GEAR

SHAFT

41T GEAR

SPACER

BEARING

SEAL

KEY

SHIFT INDEX

SPRING

FORK

FORK

SHIFT DRUM

SHIFT SHAFT

O-RING

DOWEL PIN

DOWEL PIN

Wear protective eye wear when installing spring.

SPRING TABS

SHIFT INDEX

SHAFT MUST BE IN PLACE

WHEN INSTALLING SPRING

Loading...

Loading...