110-392 10

External Piping

General Considerations

It is the user’s responsibility to ensure that the tubing and fittings connected to the Chiller are compatible with the

fluid, temperature, and pressure being used.

• All external piping, tubing, or hoses should be run full size to limit the potential for external pressure drops.

The use of quick-connect fittings is not recommended, as they can cause substantial pressure drops.

• Materials of construction should be compatible with the fluid being used as well as the temperature and

pressure at which the unit will operate.

• Where applicable, always use a back-up wrench when making piping connections to the Chiller.

• Pressure Ratings – Hoses should be able to withstand the highest pressure that they will encounter (100 psi

/ 6.9 bar).

• Flexible Tubing – Avoid tubing that will expand and increase fluid volume when operating at the desired

pressure.

• Hose Diameter – The fittings on the Chiller’s process fluid lines are female 0.5 in NPT. The facility water fluid

inlets and outlets on water-cooled models are female 0.75 inch NPT.

• Facility Water (water-cooled models only) – Should be clean and well maintained. Ideally, the facility water

should be tested monthly to ensure a pH level between 7.2 and 7.8. Add algaecide if algae growth is

present.

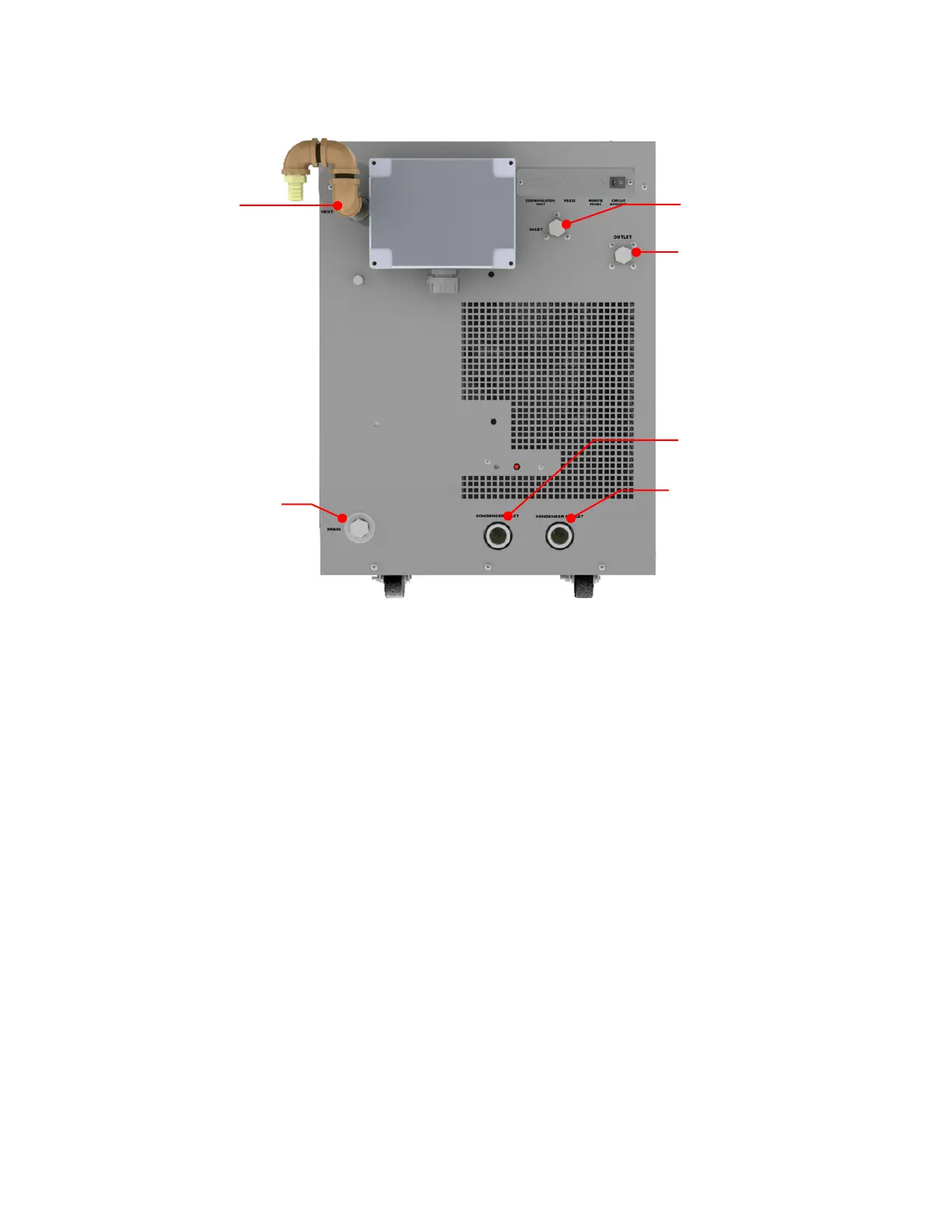

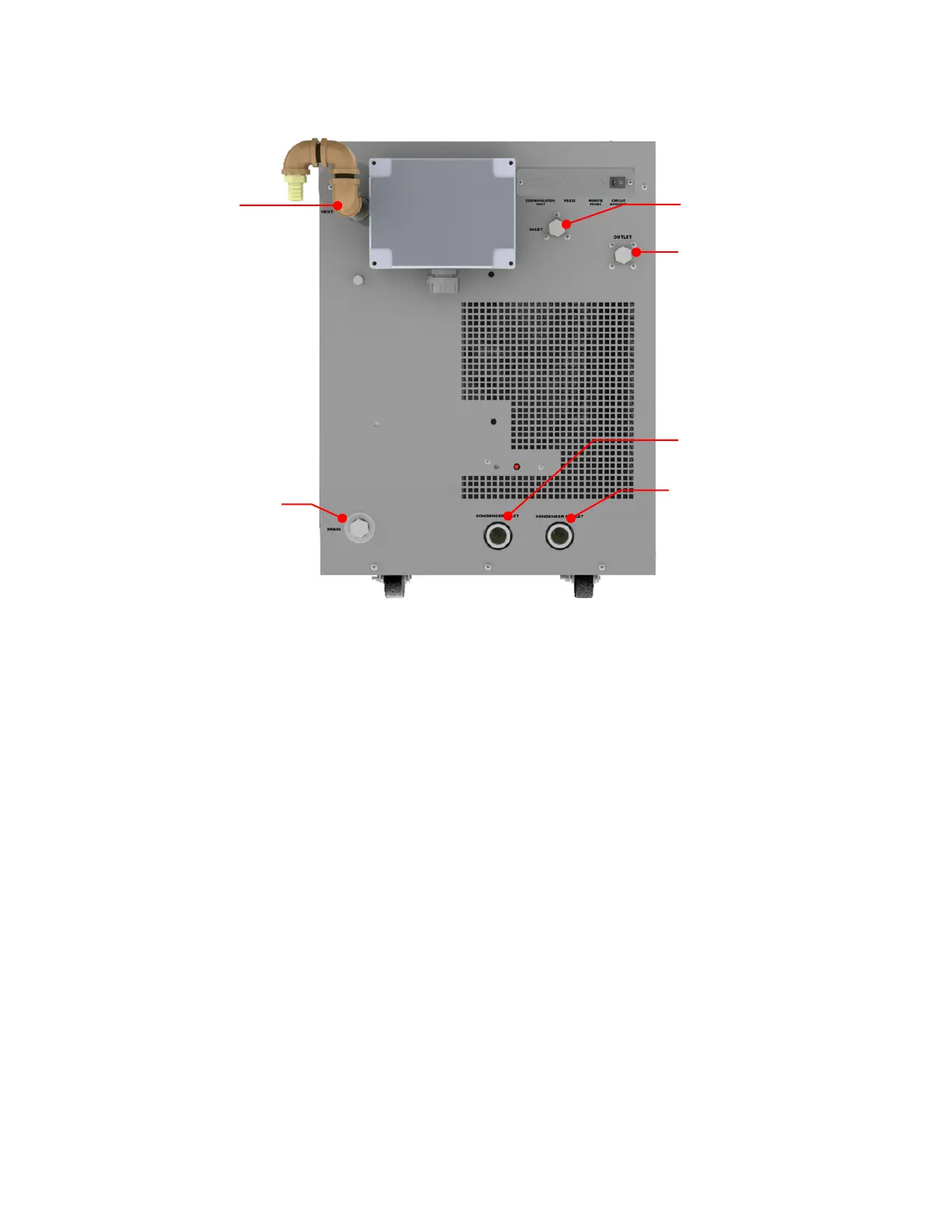

Reservoir Vent

(shown with Vent

Assembly for

5XXX models))

Loading...

Loading...