Powered by Safety

®

20

Usage

Circuit Breaker Monitor

01.4IB.48070A

Ch 5 Usage

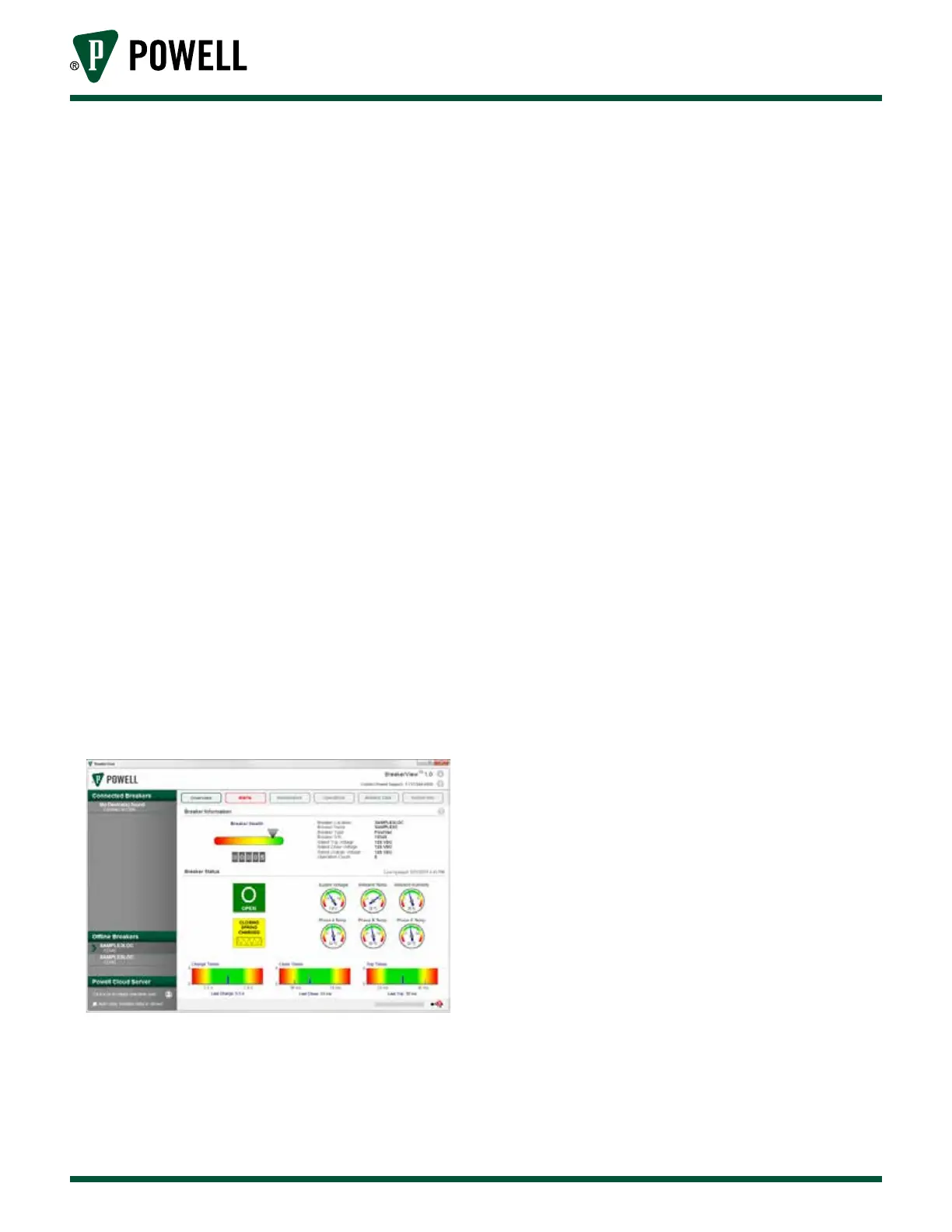

A. SoftWAre overvIeW

Powell's BreakerView software provides

a series of screens with dashboards and

values that permit rapid determination of

the overall health of a circuit breaker. This is

an asset management tool in direct support

of condition based maintenance as a more

targeted data driven version of predictive

maintenance. Any operational performance

issues are identified and diagnostics with

corrective actions provided. Recording of

events is provided in the embedded database.

Corrective maintenance as well as any routine

maintenance records can be created and stored

within the embedded database allowing a

more complete record of performance of the

circuit breaker and efforts required to ensure

its reliability. Trending of the circuit breaker

performance and time required to maintain it

is readily available through use of this software

(Figure 20), refer to BreakerView software

manual for more details.

Figure 20 BreakerView Overview Screen

Configuration of the CBM will be performed

by factory personnel or Powell Service Division

personnel.

Figure 20 shows BreakerView screen with

dashboards providing circuit breaker health

and performance measures.

The software can be downloaded from

breakerview.powellind.com.

For IRIMs that are to be used in a network, a

configuration of those modules is required

(Figure 21). Configuration of the IRIM, by a

separate application, permits the switchgear

section to have a specific ModBus address

assigned. With this methodology, any circuit

breaker with an embedded CBM will be

identified with its switchgear location, thus

circuit breakers can be installed within any

cubicle for which they have the correct rating

and will be locatable via BreakerView. The IRIM

Production Assistant will be launched from a

laptop directly connected via a USB cable to

the associated EIM to the connected IRIM.

Communications to a CBM via Modbus will

be degraded while a laptop is connected

to a given EIM through the USB. The

system is designed to respond to the

local USB connection as the primary data

communications port.

Loading...

Loading...