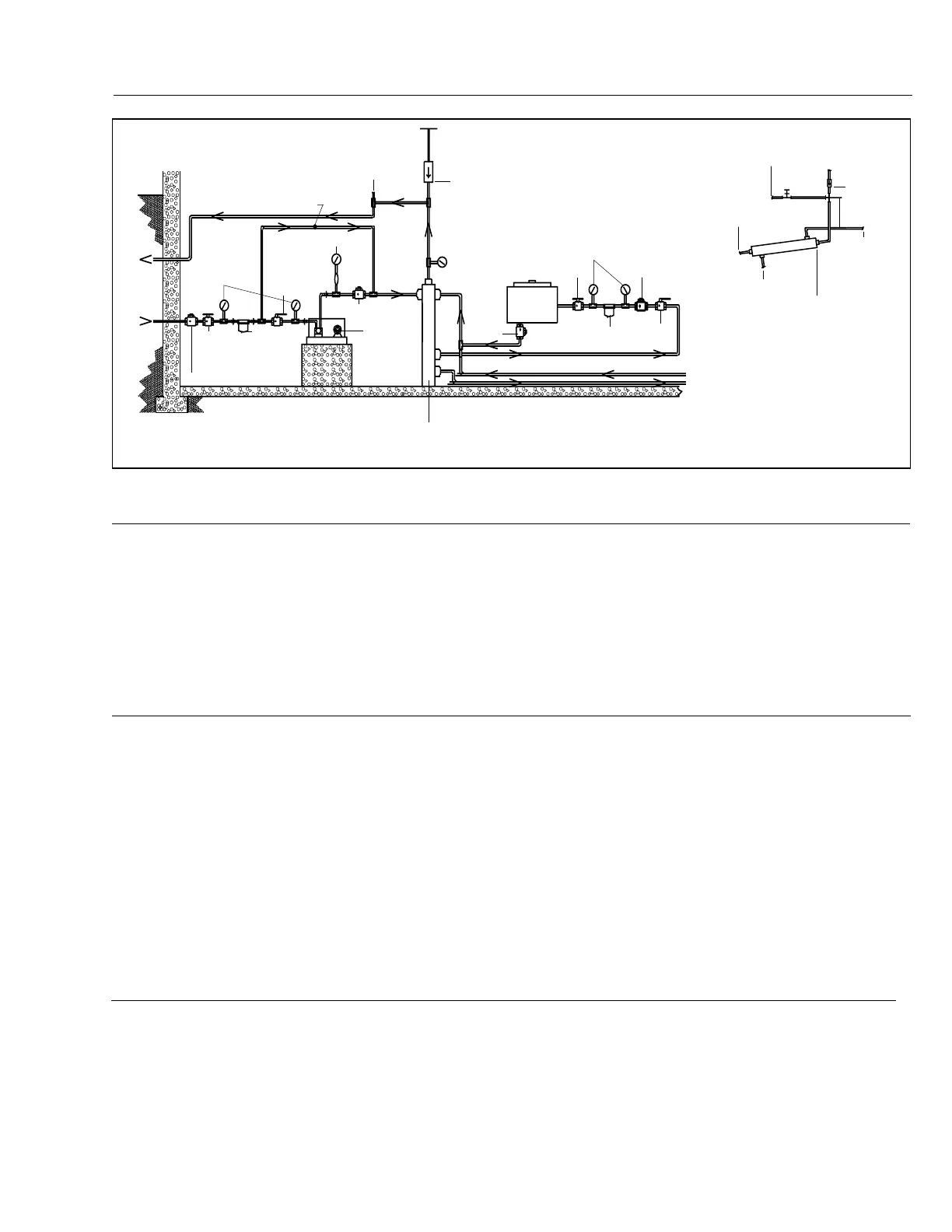

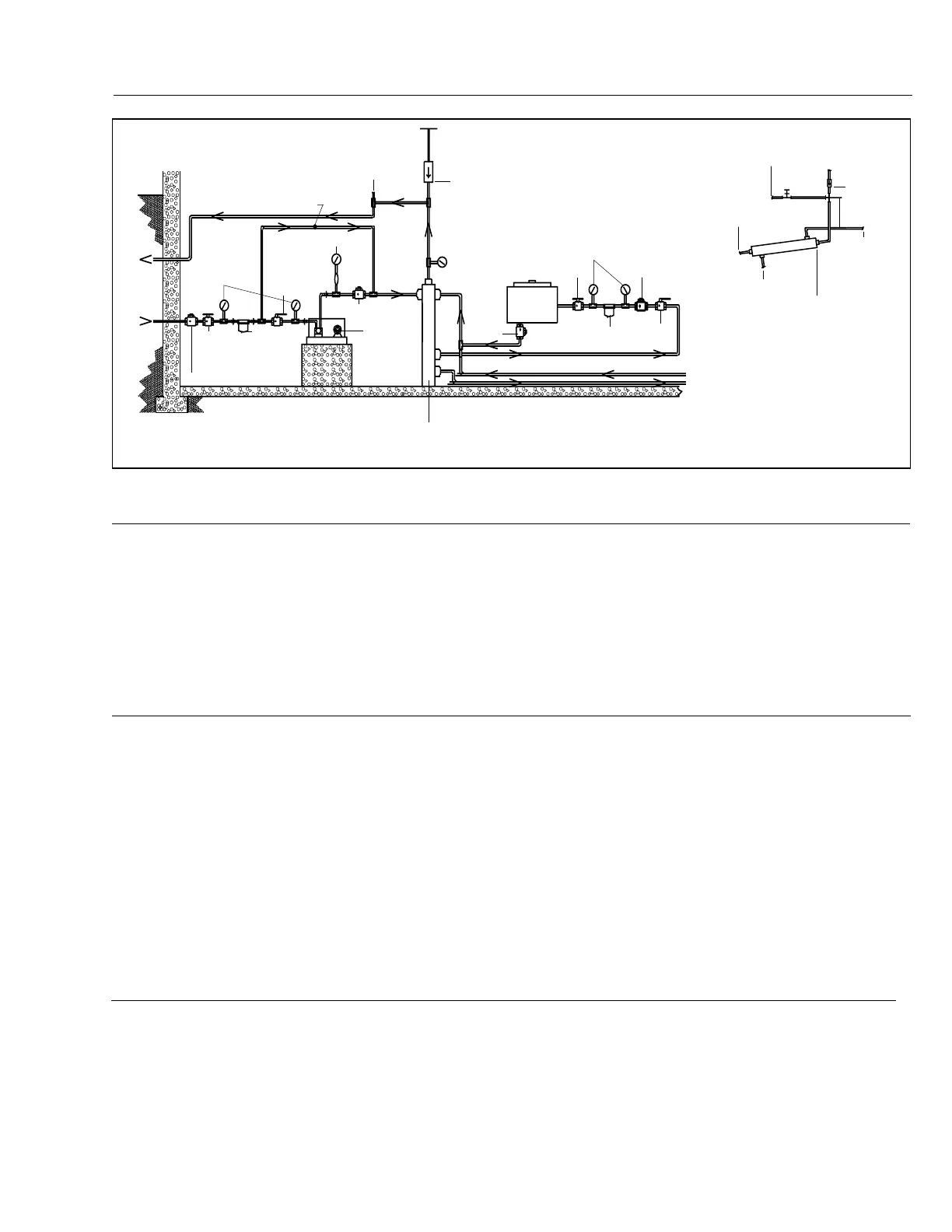

Multiple Burner System Oil Piping Schematic (Flooded Suction)

Figure 12

Combustion Chamber - General

Combustion chambers shall be provided as

recommended in Chamber Dimension Charts, and

should be constructed of high temperature refractories,

in the form of firebrick or rammed plastic refractory,

backed by suitable heat insulating material.

Certain types of heat exchangers, such as warm air

furnaces, some hot oil heaters, wet base steel and cast

iron packaged firebox boilers and Scotch marine boilers,

use the combustion chamber to transfer heat, and

therefore do not require refractory or other insulation.

If in doubt, consult the heat exchanger equipment

manufacturer.

Where boilers are of the mud-leg type, refractory should

extend 6" to 8" above the bottom of mud-leg.

All possible points of air infiltration or ex-filtration must

be sealed. If the unit is to be fired under positive

combustion chamber conditions, extreme care must be

taken to ensure that a 100% seal is maintained.

The Type C burner is designed to provide all the air

required for complete and efficient combustion.

Entry or loss of air from sources other than the firing unit

will decrease its overall combustion and operational

efficiency. See page 14, Figures 13 through 16 and

Table 7 for additional information.

Return

to Tank

Inlet

From

Tank

Press Gauge with

Snubber

Check Valve

Vent

Vacuum Breaker

Return Line

Press Test

Burner

Circulating Oil Reservoir

(May Be Placed Horizontally,

see Detail A)

Additional

Burners as

Req’d.

Detail A

Vent

Vacuum

Breaker

12” Min.

Fresh air required to support combustion, as well as to

provide adequate location ventilation, must be supplied.

All types of fuel require approximately 12 cubic feet of

standard air (sea level at 60 F

o

) per 1000 BTUs firing rate,

for theoretical perfect combustion. In actual practice,

a certain amount of excess air is required to ensure

complete combustion, but this can vary substantially

with specific job conditions. Additional air is lost from

the boiler room through barometric dampers, draft diverters

and similar venting devices. It is generally accepted that

½ square inch of free air opening (for each gas or oil

burner in the room) per 1000 BTU/hr. firing rate will be

adequate. Under no circumstances should a boiler

room be under negative pressure. Jurisdictional

authority relating to combustion air and boiler room

ventilation requirements vary widely. In order to make

certain of compliance, review NFPA-54 and the controlling

authorities should be consulted.

Combustion Air Requirements

Burner Mounting - General

A properly installed and adjusted burner is the lowest cost

maintenance insurance you can buy.

Provisions should be made to provide adequate space

around the burner and associated equipment to allow for

ease of inspection, maintenance and service.

Observe codes for the minimum clearances to combustible

materials.

Provide a suitable burner front plate, consisting of a steel

plate of ample thickness to support the weight of the burner

and hold it firmly in alignment with the heat exchanger. The

front plate must be protected from heat using high temperature

refractory on firebox side (as applicable).

To install the burner, a circular opening must be cut in the

steel front plate. Four (4) mounting bolts must be

installed at proper locations to match the mounting holes

provided on the burner mounting flange. (See dimen-

sional drawings, page 5.) The burner mounting flange

must be securely attached to the front plate with suitable

gasket or non-asbestos, high temperature rope packing to

prevent any products of combustion from escaping from

the combustion chamber. The burner assembly should

be supported at the base of the housing to prevent undue

strain on the front plate. (A mounting pedestal is furnished

for this purpose.)

Type C burners are furnished with a lifting lug for ease of

handling and mounting.

Compound

Gauges

Standby Equipment

Same as Shown Below

Shut Off

Valve

Check Valve

Oil

Strainer

or Filter

Power

Flame

Pump Set

Fusible Valve

Strainer

Shut

Off Valve

Check Valve

Compound

Gauges

From

Supply Pump

Connection

To Tank Return

To Burner Pump

Suction Connection

Pitch ¼” Per Ft.

Upward Toward

Return End

To Burner

Pump

Return

Connection

Fusible

Valve

Fill Tee with Plug

(Highest Point)

Check

Valve

Rev.304

C13

Loading...

Loading...