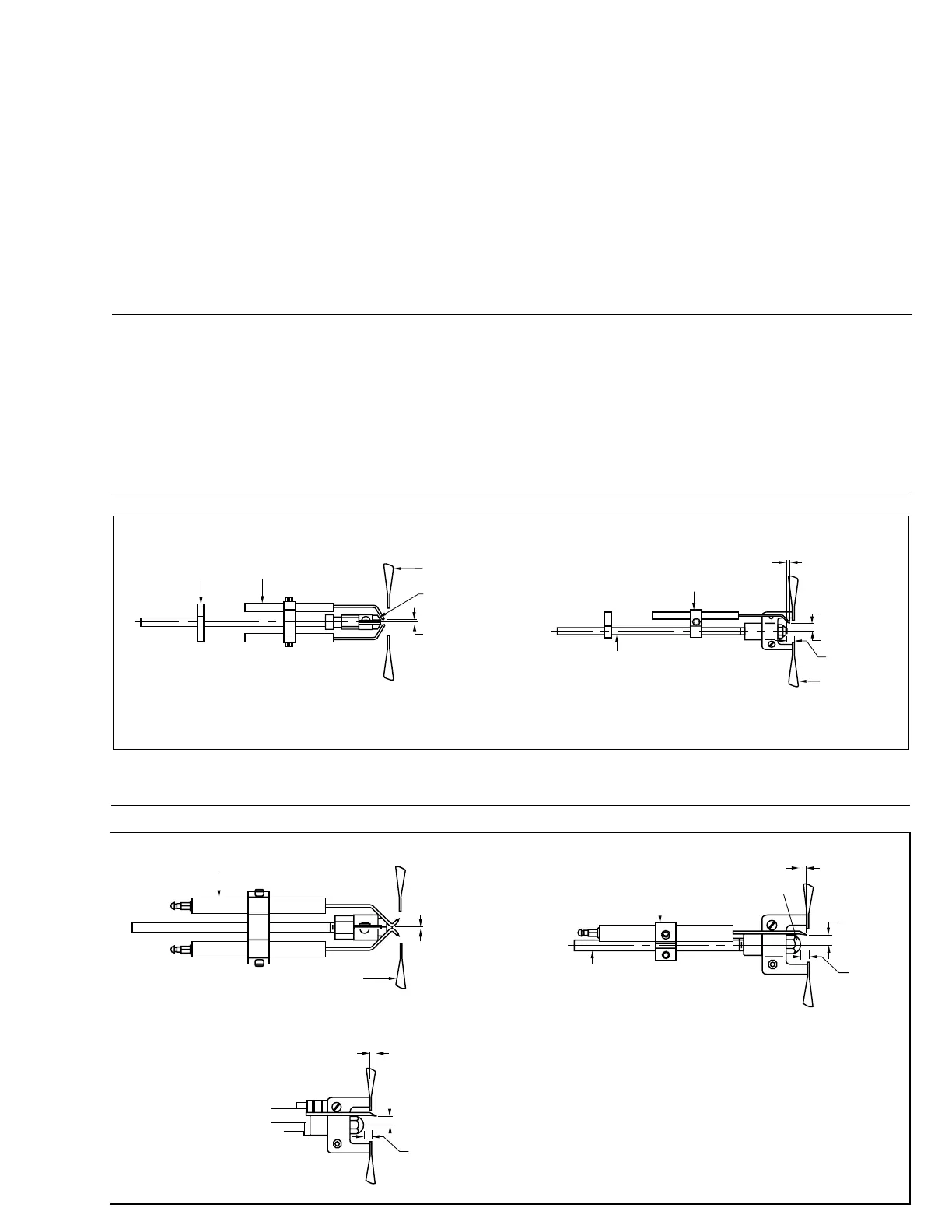

Ignition Electrode &

Porcelain Insulator

Stainless Steel

Fan Diffuser

1

/

16

”

1

/

8

” N.P.S. Brass Pipe

Ignition Electrode Support

1

/

4

” From Nozzle Tip to Electrode Tip

Nozzle

Typical Electrode Setting

For Most Non-Pressurized

Combustion Chambers

5

/

16

”

1

/

4

”-

5

/

16

”

5

/

16

”

5

/

16

”

3

/

16

”

Typical Electrode Setting

For Most Pressurized

Combustion Chambers

Figure 31

Oil Drawer Assembly Jacobs Ladder Electrode Settings

Figure 30

Oil Drawer Assembly Tip Point Ignition Electrode Setting

Cable Routing

Bracket

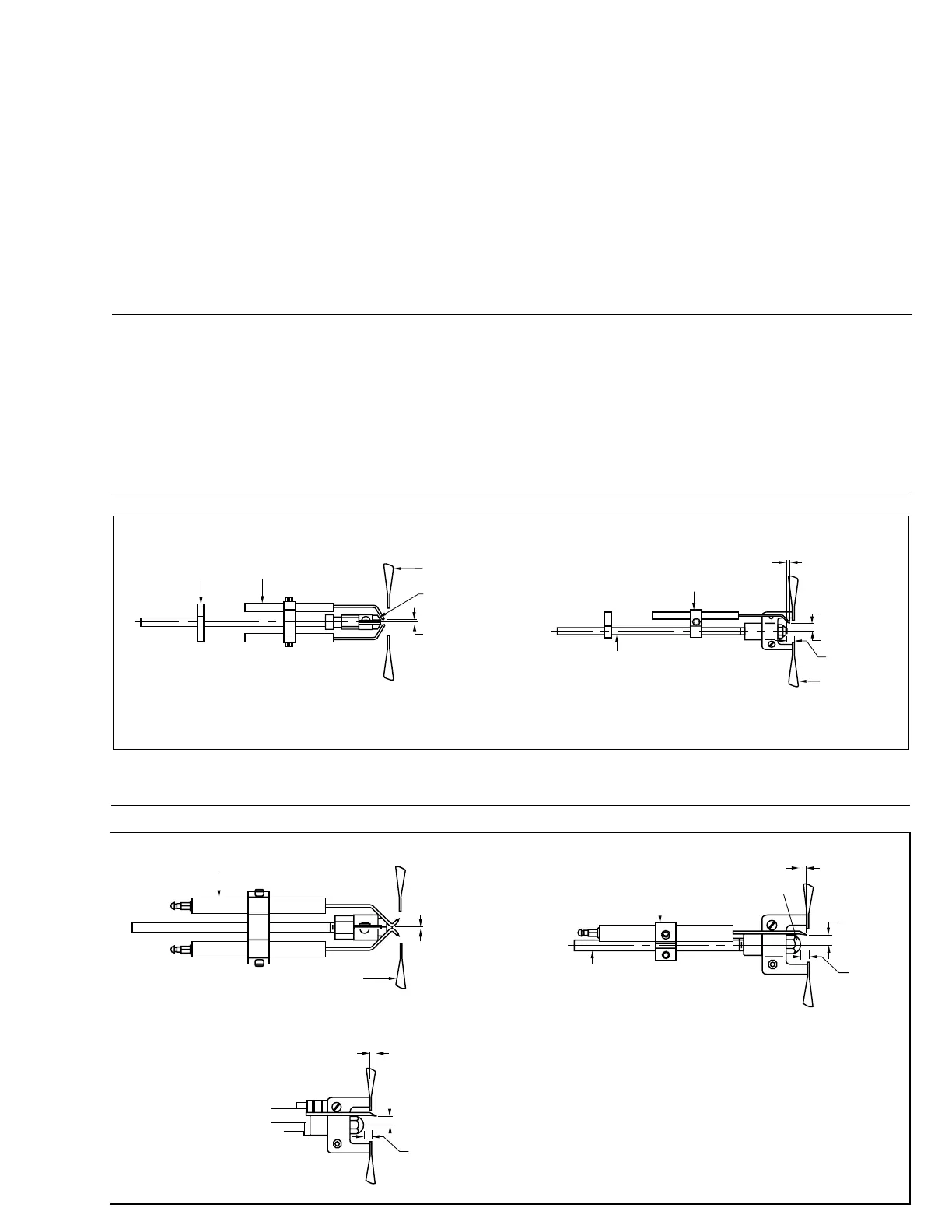

Ignition Electrode &

Porcelain Insulator

(Optional)

Certain OEM applications may require

alternate settings. Setting of electrodes

closer to center of nozzle and/or farther

forward may be required.

Stainless Steel

Fan Diffuser

Nozzle

1

/

8

” to

3

/

16

” Gap

Ignition Electrode

Support

1

/

8

” N.P.S. Brass Pipe

Stainless Steel

Fan Diffuser

5

/

16

” for

60

o

Nozzle

1

/

4

” From Nozzle

Tip to Electrode

Tip

3

/

8

” for

80

o

Nozzle

5

/

16

”

Direct Spark Oil Ignition Adjustments

1. The ignitor assembly should be removed and

cleaned regularly. The porcelain insulators should

be kept clean and must be replaced if cracked.

2. The spark gap must be set in accordance with the

dimensions noted. (Refer to Figures 30, 31, 32).

Ensure that the distance between the electrodes and

the nozzle (or diffuser) is greater than the spark gap.

3. The electrodes should not extend closer than

1

/

8

" to

the spray angle of the nozzle to prevent carboning.

A nozzle spray angle check card is available and

may be used to check electrode position.

4. The high tension wires and clips between the

transformer and ignitor electrodes should be

checked periodically for deterioration.

PUMP LEAKS

1. Cover bolts need tightening; gasket broken or

defective

2. Mechanical seal (used on certain models) may be

scratched, due to dirt

3. Inlet head pressure too high. Install a pressure

reducing valve set at 3 psig or less

4. Oil line fitting not tight

CAPACITY TOO LOW

1. Suction lift too high (see page 12, Figure 10)

2. Air leak in suction line

3. Suction line too small (see page 12, Figure 10)

4. Check valve or strainer is obstructed or dirty

5. Mechanical defects - pump badly worn or seal

defective

For additional oil pump information, refer to the oil pump

manufacturer’s product bulletin supplied with the burner.

C35

Rev.304

Loading...

Loading...