Note 2

Component operational sequencing will vary with the specific

Flame Safeguard Control being used. Refer to the specific

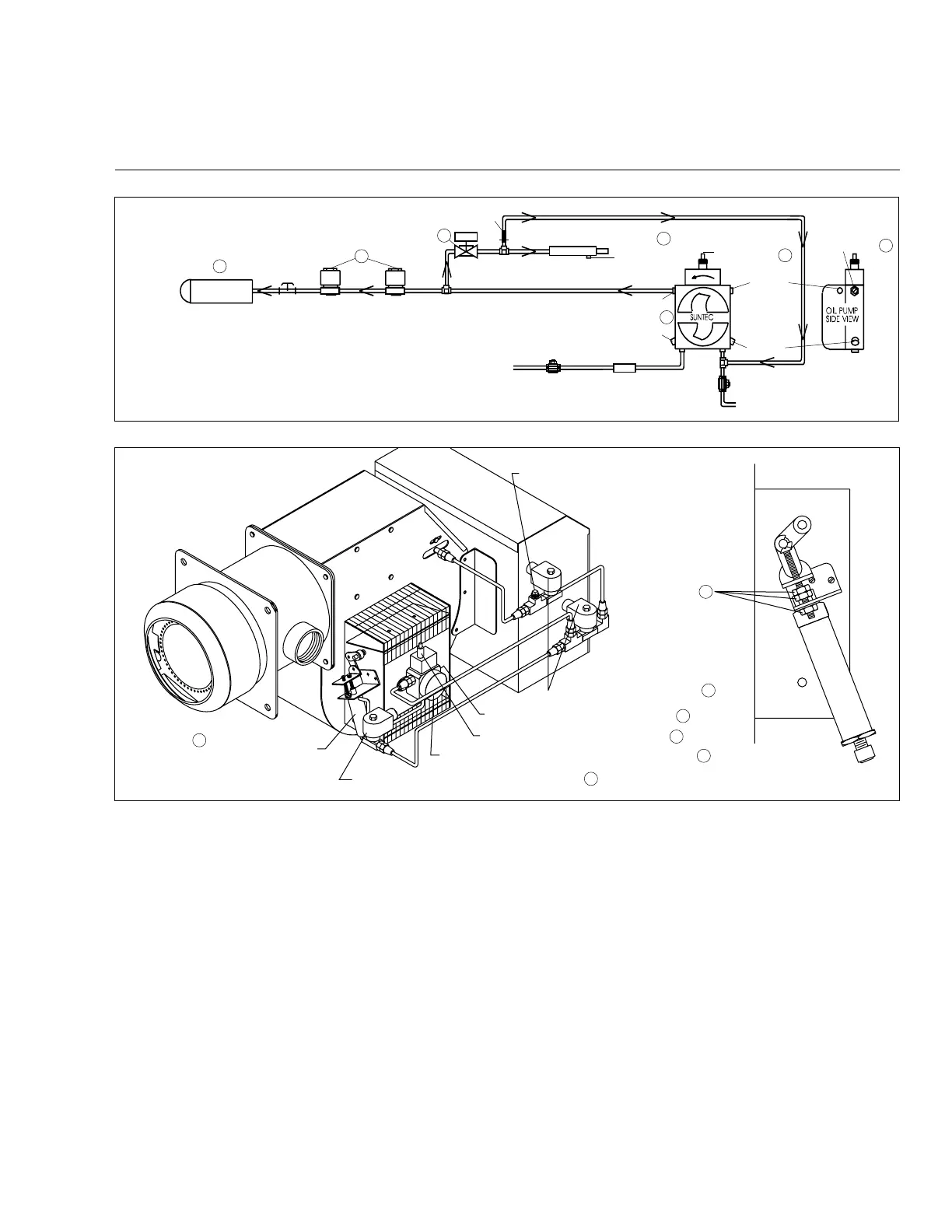

MECHANICAL OPERATION: The RALFS system uses a two

step, two stage dual pressure Oil Pump (6), or fuel unit, with a

simplex nozzle. Either a direct spark or a gas pilot ignition

system may be provided for ignition of the main oil flame.

The air damper is spring loaded to an open position suitable

for maximum desired capacity and proper combustion.

OIL CYCLE: After a 30 second pre-purge is accomplished,

the direct spark ignition transformer is energized. At the

same time the normally closed Cylinder Solenoid Valve (4)

is energized, moving the Hydraulic Cylinder (5) and air

damper to a reduced air setting (combustion air dampers

approx.

3

/8” open). Combustion air is to be set by loosening

the set screws from the damper arm that connects to the

damper shaft. Set the damper opening so as to provide a

smooth and immediate light-off. The amount of combustion

air needed for this temporary setting should be minimal-

just enough to prevent the unit from producing smoke. A

smooth light off with minimal air is the objective. The Low

Fire Pressure Adjustment (7) or the light-off fuel setting

should be set between 90 p.s.i. to 120 p.s.i. After the air

dampers have been driven to the reduced air setting or

light-off fire position the Safety Oil Solenoid Valves (3) will

be energized by the flame safe-guard igniting the low fire

oil flame or the light-off flame which is proven by

flame sensor (scanner). After approximately five

seconds, the normally closed Cylinder Solenoid Valve

will be deenergized, causing the combustion air damp-

ers to open to the fixed air setting for maximum desired

capacity. The return oil valve (normally open) which is

integral to the Suntec two step pump (fuel unit) will now be

energized, providing full high fire oil pressure for the oil

nozzle. At the same time, the main oil valve terminal

on the flame safeguard will be energized and the

Safety Oil Solenoid Valves will open. The adjustment

for fixed air setting or full fire position will be made

with the two bottom

1

/4-20 hex nuts - see item #1.

Combustion air dampers should be adjusted to provide

11

1

/2 to 12

1

/2% CO

2

or 4 to 5

1

/2% O

2

at full input (oil high

fire rate) with zero smoke. High Fire Oil Pressure (8)

setting should be set to the required p.s.i. for high fire oil

rate (see burner specification sheet for setting). The low

fire should be rechecked for light-off pressure and

performance. The gas combustion will be initiated

(after 30 seconds pre-purge period) by proof of spark

ignited gas pilot (by scanner) which energizes dual gas

safety valves. If input for gas is comparable to oil input

then previous air damper adjustment for oil combustion

should be satisfactory for gas firing.

Flame Safeguard Control bulletin supplied with the burner for

complete information.

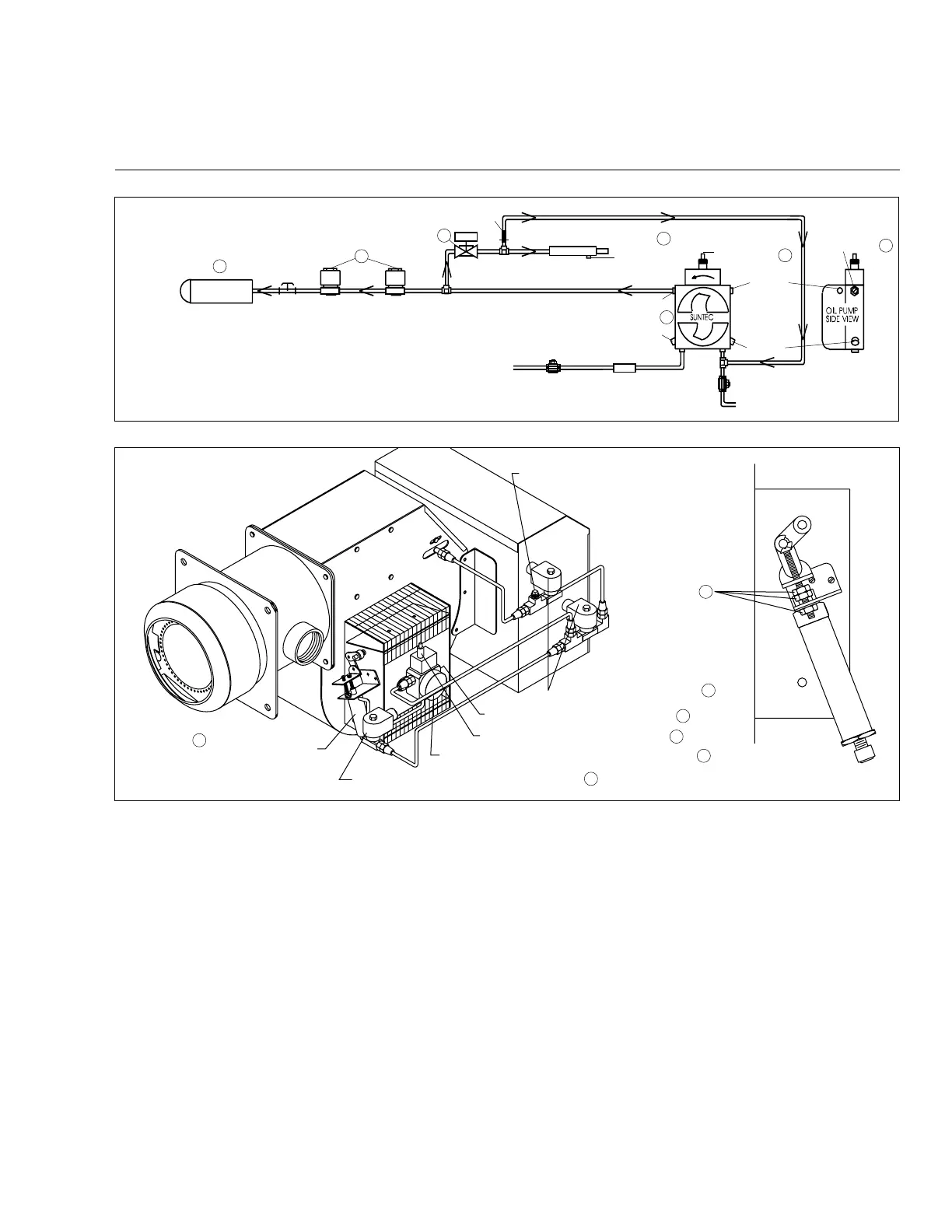

Nozzle Pressure Test Port

Figure 22

Typical Oil or Gas/Oil Burner with Reduced Air, Low Fire Start RALFS

Simplex Nozzle

Nozzle

Pressure

Test Port

Safety Oil

Solenoid Valves

N.C. Cylinder

Solenoid Valve

#72 Drill Orifice

Hydraulic Cylinder

Atmospheric

Vent

Nozzle Port

Pressure Test Port

Return to Tank

Check Valve

(By Others)

Inlet From Tank

Check Valve

(By Others)

Pressure

Test Port

Optional

Inlet Port

Strainer(By Others)

Low Fire

Press. Adj.

High Fire Oil

Press. Adj.

DO NOT USE TEFLON TAPE

2

3

4

5

7

8

6

Oil Pump

1

Normally Closed Cylinder Solenoid Valve

4

Two-Step (Dual Pressure) Two Stage Fuel Unit

6

Low Fire Oil Pressure Adjustment

7

High Fire Oil Pressure Adjustment

8

3

Safety Oil Solenoid Valves

Hydraulic Cylinder

5

C18

Rev.304

Loading...

Loading...