DS600 Non-Ferrous Double Sheet Detector

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202177 11 Revision M

simply allow the 5 second display interval to elapse. The display reverts to displaying the gauge

signal with no change to the parameter.

To change the value of a parameter, press the pushbutton and hold it for more than 3 seconds

until the appropriate parameter identifier appears on the digital display. While the desired

parameter identifier is showing on the display, release the pushbutton and the current value of

the parameter displays. Press and hold the pushbutton while the parameter value is displaying

and the value increments, first slowly then more rapidly. For more precise control of the value

adjustment, simply tap the pushbutton repeatedly until the desired value is displayed. All

parameters roll back to their minimum values after reaching the maximum value. To retain the

adjusted value of the parameter, simply allow the 5 second display interval to elapse while the

new value is displaying. The display reverts to displaying gauge signal strength.

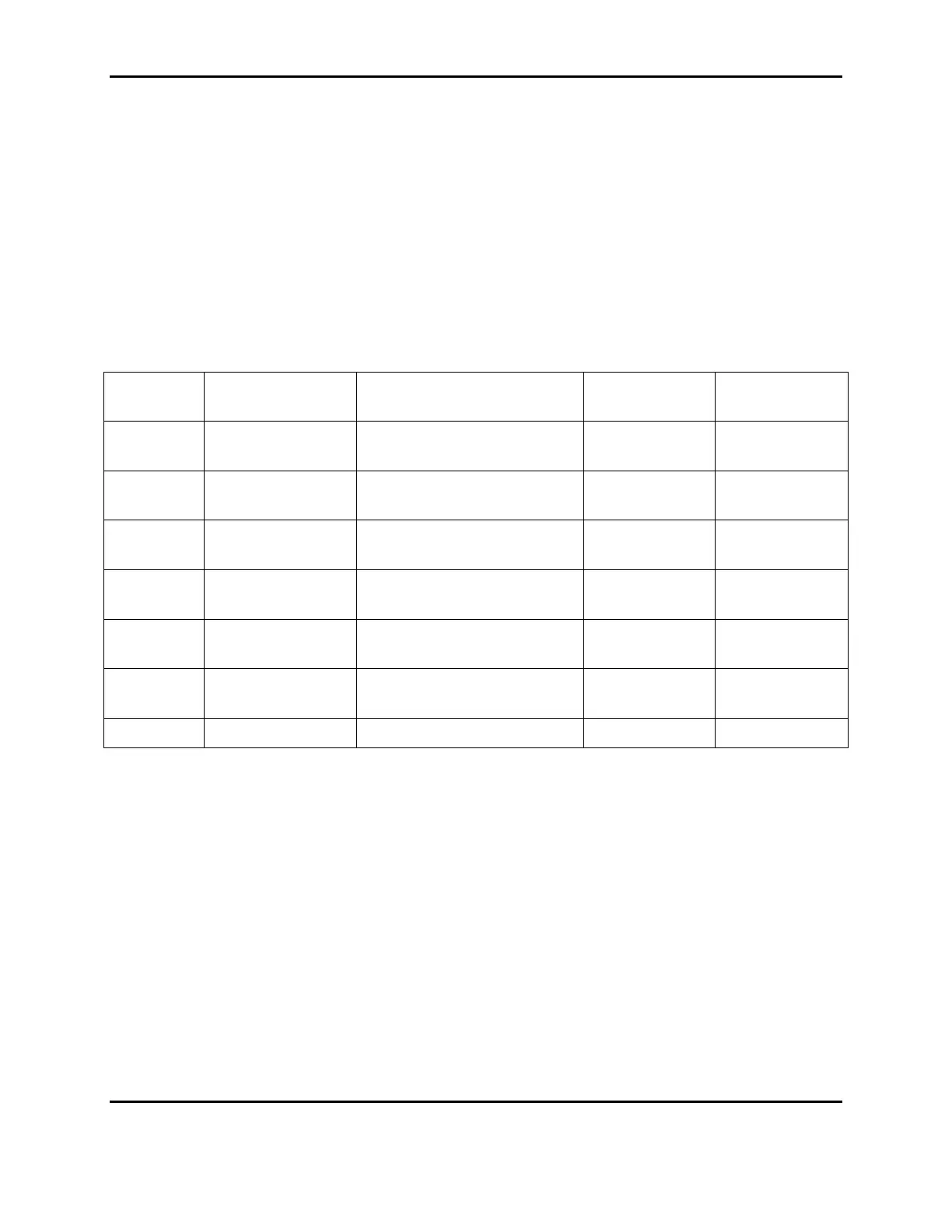

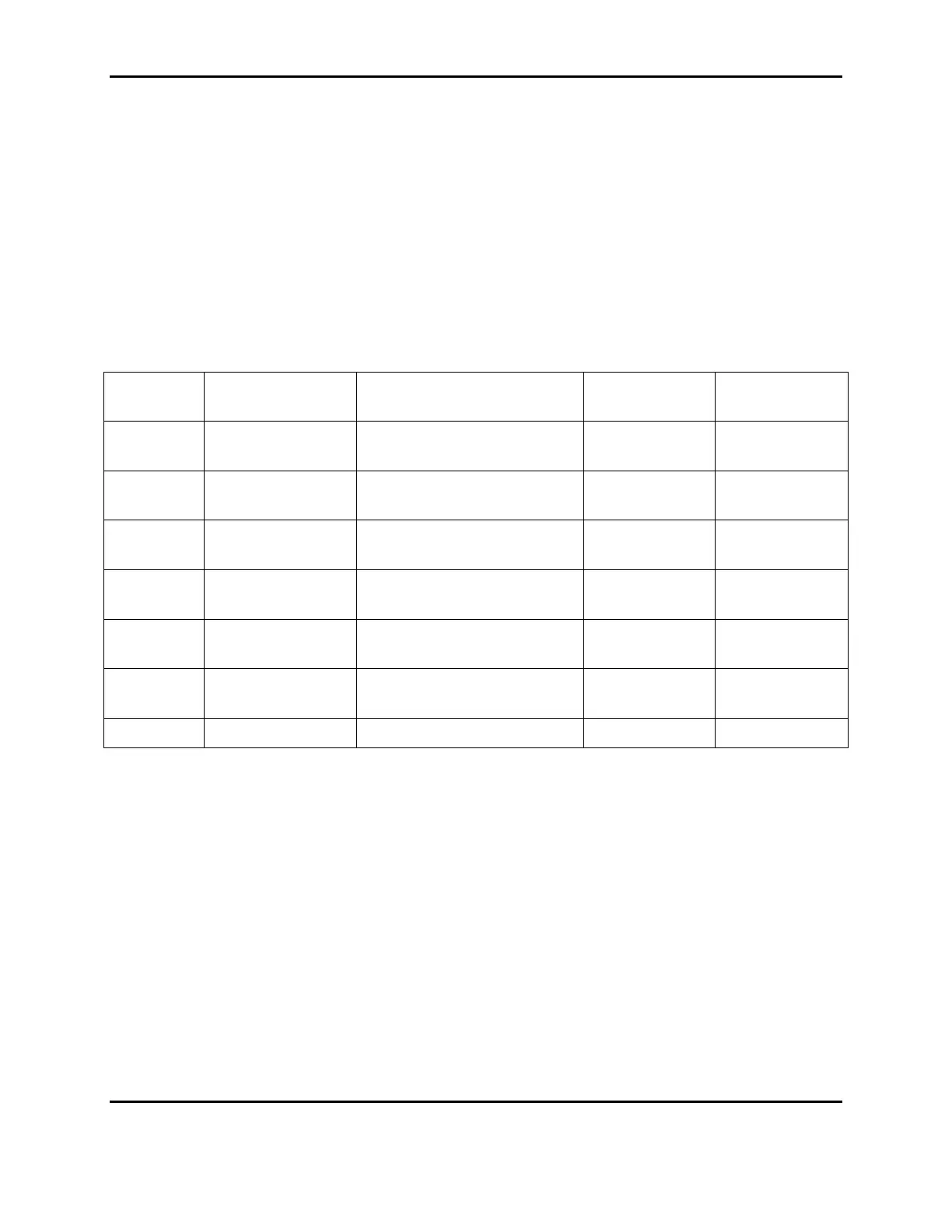

Table 3

Parameter Full Name Function Range

[Default]

Controller

Type

Selection

Select calibration memory

Selection

Select calibration memory

percentage

percentage

(Part Present)

percentage

Present Mode

Set “under” reporting delay

(hundredths of a second)

1

Modbus ID defaults to an illegal value requiring the installer to select an appropriate value for

their network.

3.4 Front Panel Display

The four digit 7 segment front panel display continuously displays the current gauge value from

0 to 100. A nominal value of 50 is displayed for metal thicknesses equal to the calibration

thickness. When not gauging, the display is used to show user prompts, status, and error

messages for the controller.

3.5 Calibration

The DS600 supports two modes of calibration, referred to here as one-point and two-point

calibration. One-point calibration requires only one sample of material of nominal thickness. Two

point calibration requires two samples of the nominal thickness material. Two-point calibration is

the most accurate and repeatable calibration method and is recommended.

Loading...

Loading...