DS600 Non-Ferrous Double Sheet Detector

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202177 14 Revision M

3. Quickly press and release the CALIBRATE pushbutton twice within one second or apply

two momentary signals to the external CAL terminal. The display alternates CAL and

Pnt1.

4. Wait for the display to change to CAL and Pnt2 then place a sample of the part present

condition in front of the probe face and press and release the CALIBRATE pushbutton or

apply a momentary signal to the external CAL terminal.

5. If the calibration is successful, the display reverts to displaying the gauge signal and

calibration is complete.

6. If the material is too thick or if the thickness measured at point 2 is very near to the

thickness measured at point 1, the display alternates showing Lo and diFF. To recover

from this condition, follow steps 6 or 7 below.

7. Restart calibration by placing a sample of the “part missing” condition before the probe

and press the CALIBRATE pushbutton once or apply a momentary signal to the CAL

terminal. Go to step 3.

8. Wait 30 seconds and the DS600 reverts to its previous state of gauging.

The gauging threshold is computed as an offset from the first point value in the direction of the

second point value. The size of the offset is computed as a percentage of the distance from the

first point to the second. The threshold computation is:

Threshold = Pnt1 - (Pnt2 - Pnt1) x Tol/100

The tolerance (Tol), expressed in percent, may be adjusted through the front panel as

parameter toL. The default value is 15%.

3.6 Calibration Save and Recall

After successful calibration, the DS600 saves the calibration in non-volatile memory. Model

DS600 saves only one calibration dataset. Model DS600P can save up to eight different

calibrations, and model DS600PC can save up to 64 different calibrations. Where multiple

calibrations can be saved, each saved calibration must be uniquely identified for later retrieval.

The identifier is in the form of a number ranging from 1 to 8 for the DS600P and from 1 to 64 for

the DS600PC.

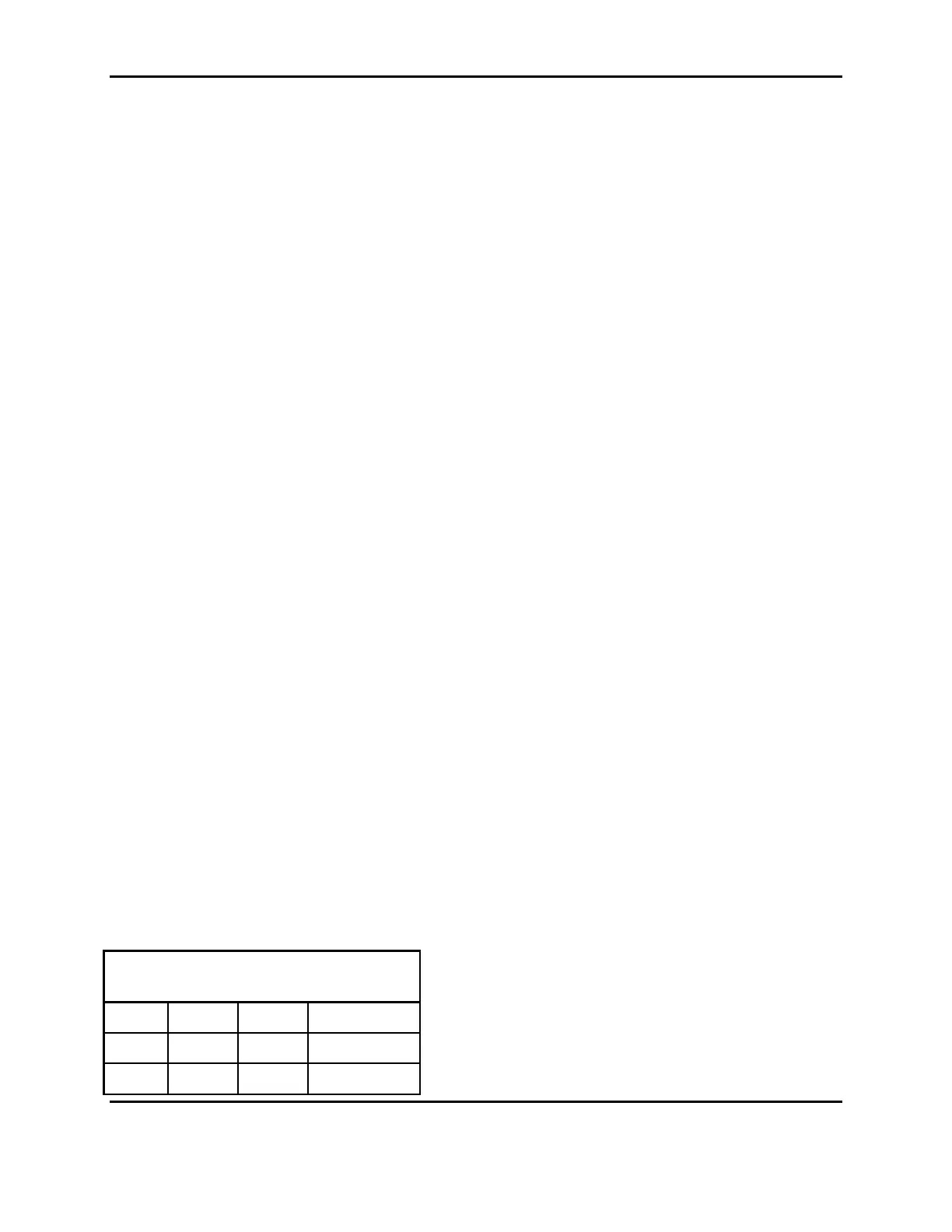

The DS600P calibration identifier (1-8) may be specified through the front panel SEL parameter

or through the signals applied to the SEL2 through SEL0 and ENABLE terminals (See Table 4).

Whenever the ENABLE signal is asserted (ON), the selected calibration is determined by the

signals applied to the SEL2 through SEL0 terminals. When ENABLE is not asserted (OFF), the

selected calibration is determined by the last memory address entered through the front panel

SEL parameter.

Table 4

SEL2 SEL1 SEL0

NUMBER

Loading...

Loading...