FM15_P28 HV PN7 (-TS) Ver I_052217IOM Template Master.indd

Page 2 of 19 P2/3 Series HV-TS AdVanced Proportional Control

Introduction

This document provides necessary information for set-up, calibration, testing and use of the P Series quarter-turn

electric actuators stated on the cover page. Each unit is shipped from the factory with initial calibration of mechanical

stops, cams and switches completed for 0-90 degree operation. However, these are general settings and serve as

a starting point for proper calibration of the actuator in its real-world application.

Safety

Safety is a basic factor any time you maintain and operate mechanical equipment. Appropriate handling methods

and proper use of tools and clothes can help prevent serious accidents -- accidents which can cause injuries

to you or a fellow worker. This manual was created to enable a trained user to install, adjust and troubleshoot

your ProMation actuator.

Only competent and trained personnel should install, maintain and operate ProMation Actuators. Any work

related to this actuator must be carried out in accordance with this manual and related codes and regulations.

Local workplace health and safety rules should always be followed.

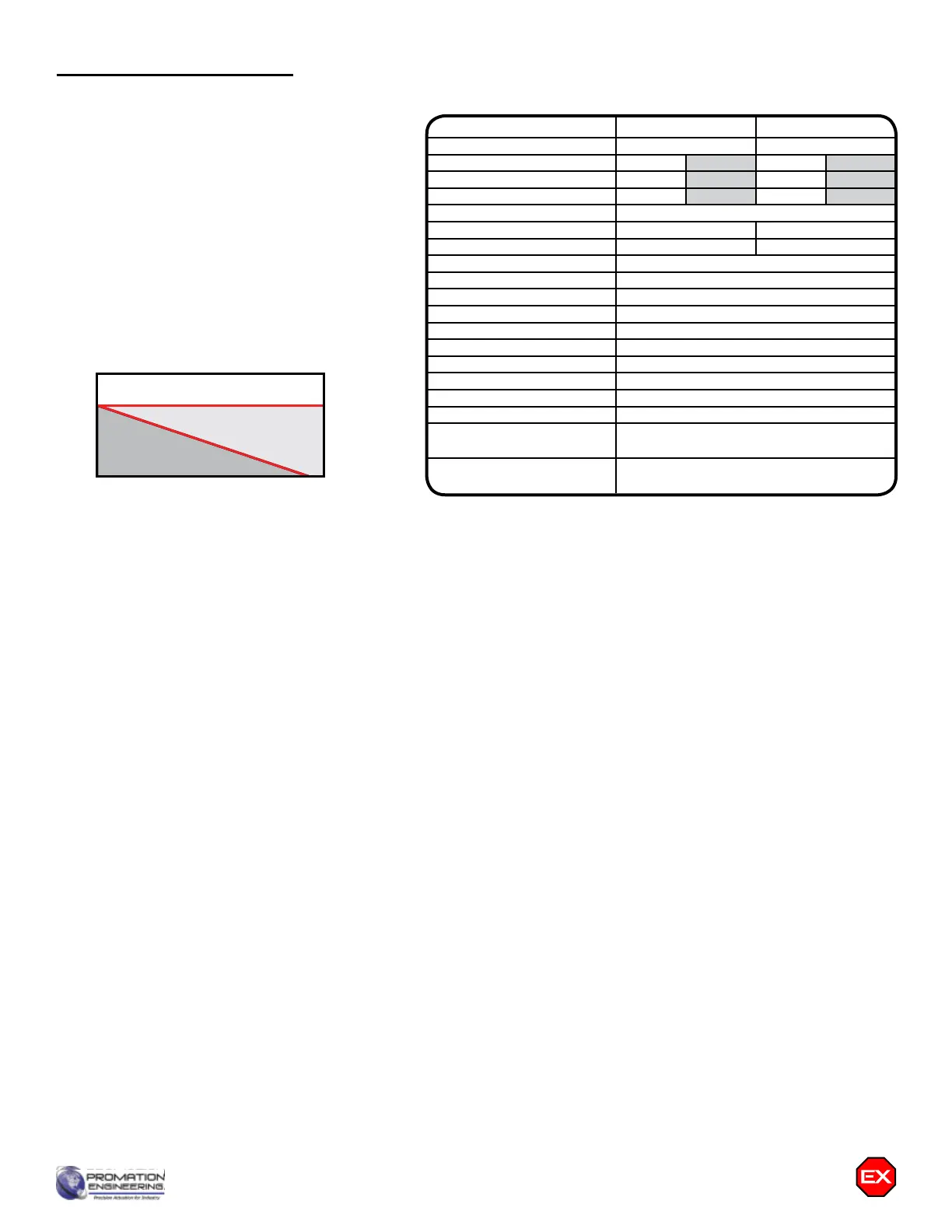

Duty cycle

Duty cycle is the percent of time that an actuator spends running as a fraction of the total time. Duty Cycle is

directly related to heat; excessively repositioning an actuator typically results in motor overheating which can

cause permanent damage and/or reduced service life.

Duty cycle can be calculated as follows:

(example P2 series actuator running 3 seconds ON and 30 seconds OFF)

Runtime = 3s, Total time = 3s + 30s = 33s, therefore this duty cycle would be 9% (3/33)

Additionally, ProMation P series actuators are designed for a maximum of 1200 starts per hour (one start every

3 seconds maximum).

50°F

10°C

75°F

24°C

100°F

38°C

125°F

52°C

150°F

65°C

25%

50%

75%

100%

On/Off/Jog

Proportional

Ambient Temperature

Page 3 P2/3 HV-PN7 Series

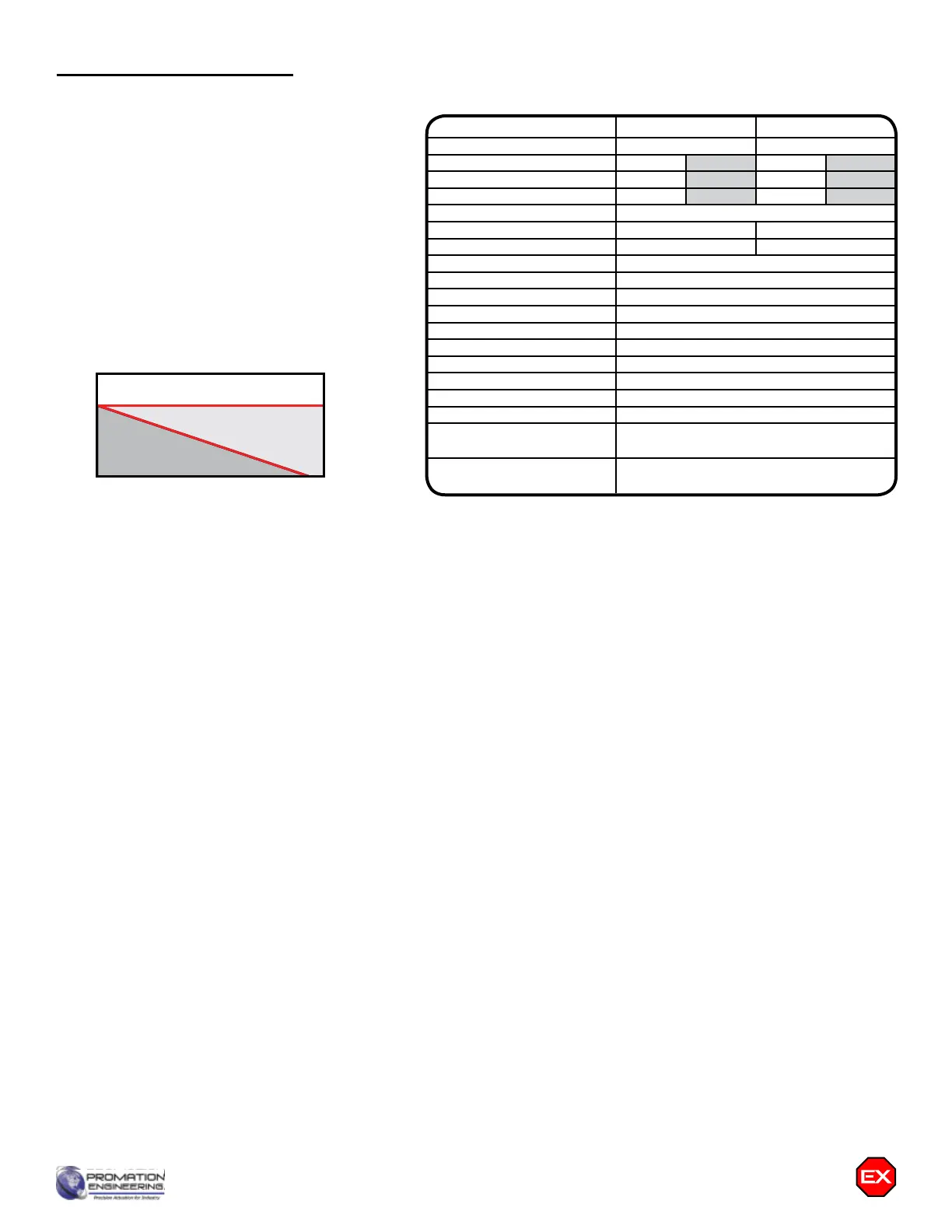

Actuator Speci cations

P2 P3

Torque “lb/Nm 800”lbs/90Nm 1335”lbs/150Nm

Supply Voltage 120vac 230vac 120vac 230vac

Max Inrush Current 1.8A 0.8A 1.8A 1.2A

Running Current 1.0A 0.5A 1.2A 1.0A

Motor Split Phase Capacitor

Runtime (90°@60Hz) 15 sec 22 sec

Runtime (90

O

@50Hz) 17 sec 26 sec

Duty Cycle Managed (75% maximum)

Motor Starts 1200 per hour

Weight 36lbs/16kg

Mechanical Connections ISO5211 F07 8pt 22mm

Electrical Entry (2) 3/4” NPT

Electrical Terminations 12-16ga

Environmental Rating Class I Division 1, Class II Division 1

Manual Override 5” Handwheel

Control Proportional

Actuator Case material Aluminum Alloy, Powder coated

Motor Protection

230°F/110°C Thermal F* Class

*Totally Enclosed Non-Ventilated Motors

Ambient Temperature

Operating Range

-22°F to +125°F

-30°C to +52°C

P23 HV PN7

Wire Sizing Chart

MAX distance between Actuator

and Supply (feet)

Actuator/

Voltage

P2

120VAC

P2

230VAC

P3

120VAC

P3

230VAC

1.8A 0.8A 1.8A 1.2A

16 722 3111 722 2074

14 1166 5026 1166 3351

12 1783 7687 1783 5125

10 3030 13068 3030 8712

8 4523 19505 4523 13003

Wire

Gage

Amps

Product Specications

Loading...

Loading...