Programming the Outputs

Page 80 of 102

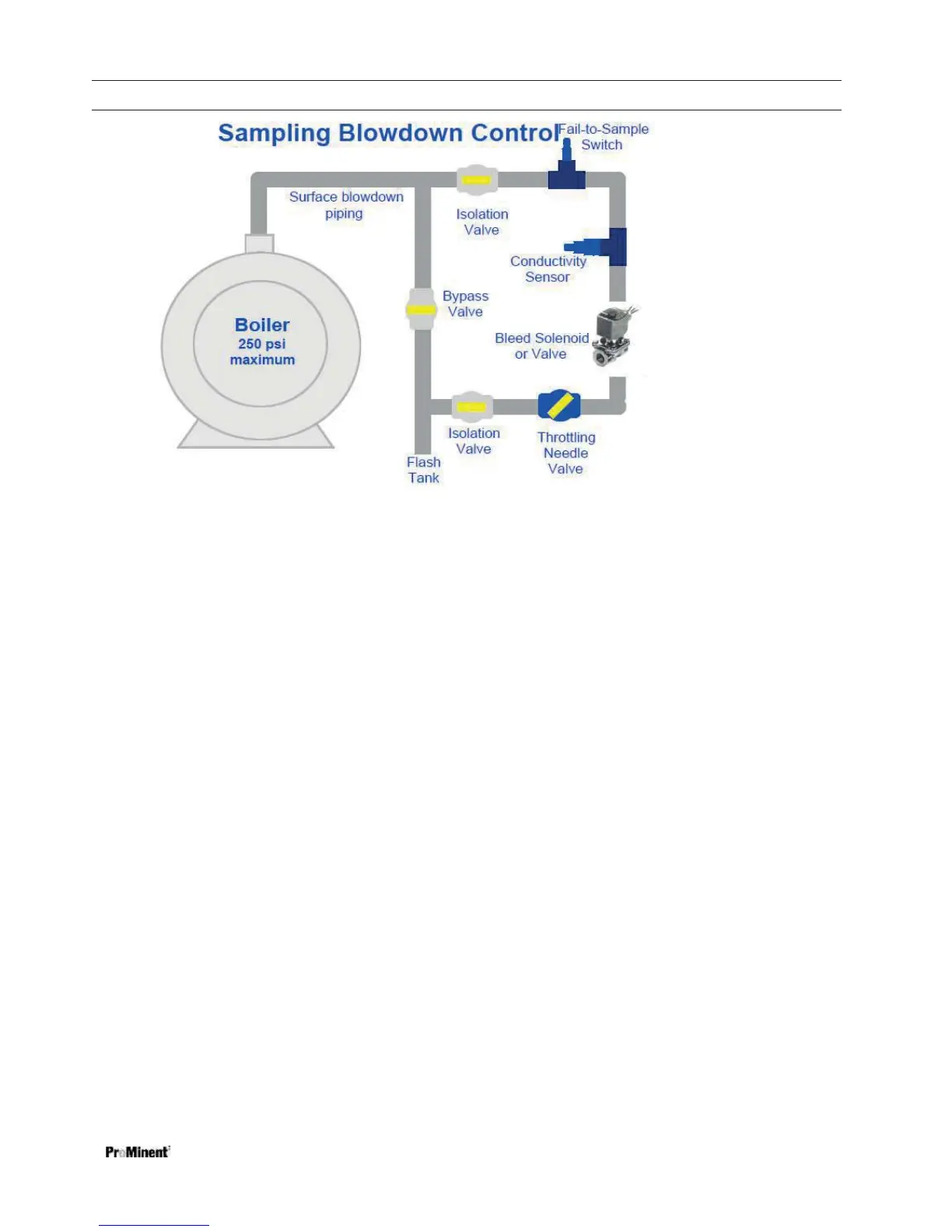

The Sample time should be set for a long enough

period that ensures a fresh sample has passed the

sensor.

The Measure time is 60 seconds. This cool down

period increases accuracy of the reading as well as

adding to the life of the probe. Typically, this value is

not adjusted.

Blowdown defaults to 120 seconds, a good starting

point.

Resample is the wait time between sample cycles.

After the resample time has elapsed, the valve

opens and takes a new sample to start over.

Basic operation:

At the start of a captured sample routine, the

blowdown valve opens for the Sample period. The

pipe at the sensor should be hot before the valve

closes.

The Measure stage holds the valve closed for 1

minute to cool the sample and get a steady reading.

The controller uses the sensor value at the end of

the measure period. This sensor reading is

converted to a conductivity value and compared with

the set-points. If too high, a blowdown step is

started. If below the turn off set-point, the blowdown

step is skipped.

The Blowdown valve is now opened for the set time

and closed. A second measure time is started,

allowing the sample to cool as before, read the

sensor and compare it to the set-points. As long as it

is above the turn off point, the controller will oscillate

between the measure and blowdown steps.

Once the conductivity low level is reached, the

Resample timer holds the valve closed until the

next cycle starts.

NOTICE:

If the routine is not keeping the boiler conductivity

within the preferred range, consider these

adjustments;

Conductivity rises: 1) If the conductivity rises too

much between samples, decrease the resample

delay time (Run the routine more often).

2) If the measure/blowdown steps are repeating

without stop, lengthen the blowdown time or open

the restriction to allow more flow.

Remember, opening the restriction moves you closer

to losing control of the flashing. Adjust in small

amounts and monitor 2 or 3 cycles before approving

the change.

Loading...

Loading...