n Keep the suction line as short as possible.

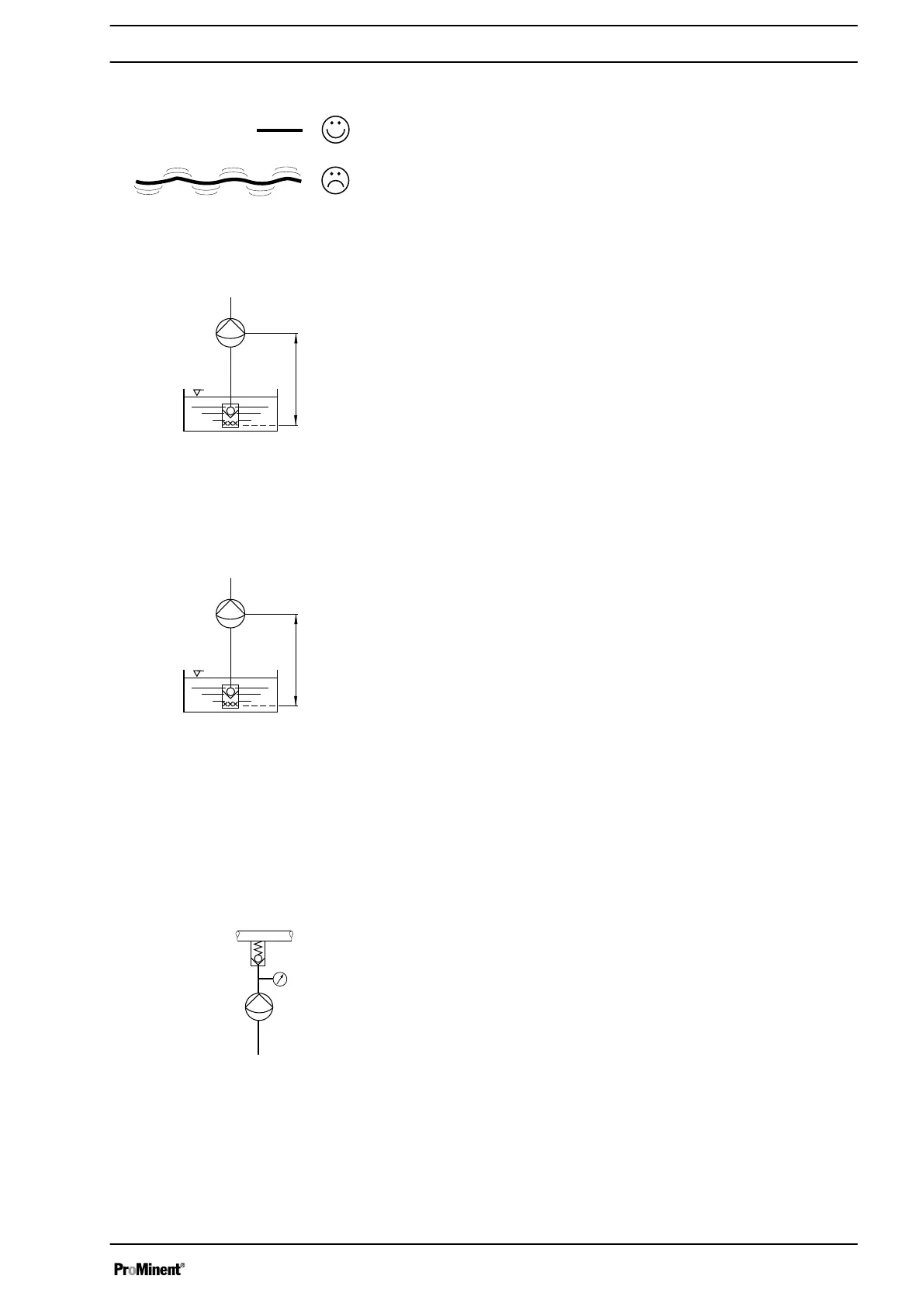

n The height h (see diagram) may only be smaller than or equal

to the suction lift of the pump P divided by the density rho of

the feed chemical:

h (in m)≤ P (in mWS) / rho (in g/cm

3

)

n The height h - see diagram - and the cross-section of the suc‐

tion line must be dimensioned in such a way that the negative

pressure created during the suction process cannot reach the

vapour pressure of the feed chemical being metered (cavita‐

tion!).

This can be seen in extreme cases by the dropping of the fluid

level or by an incomplete reciprocal stroke.

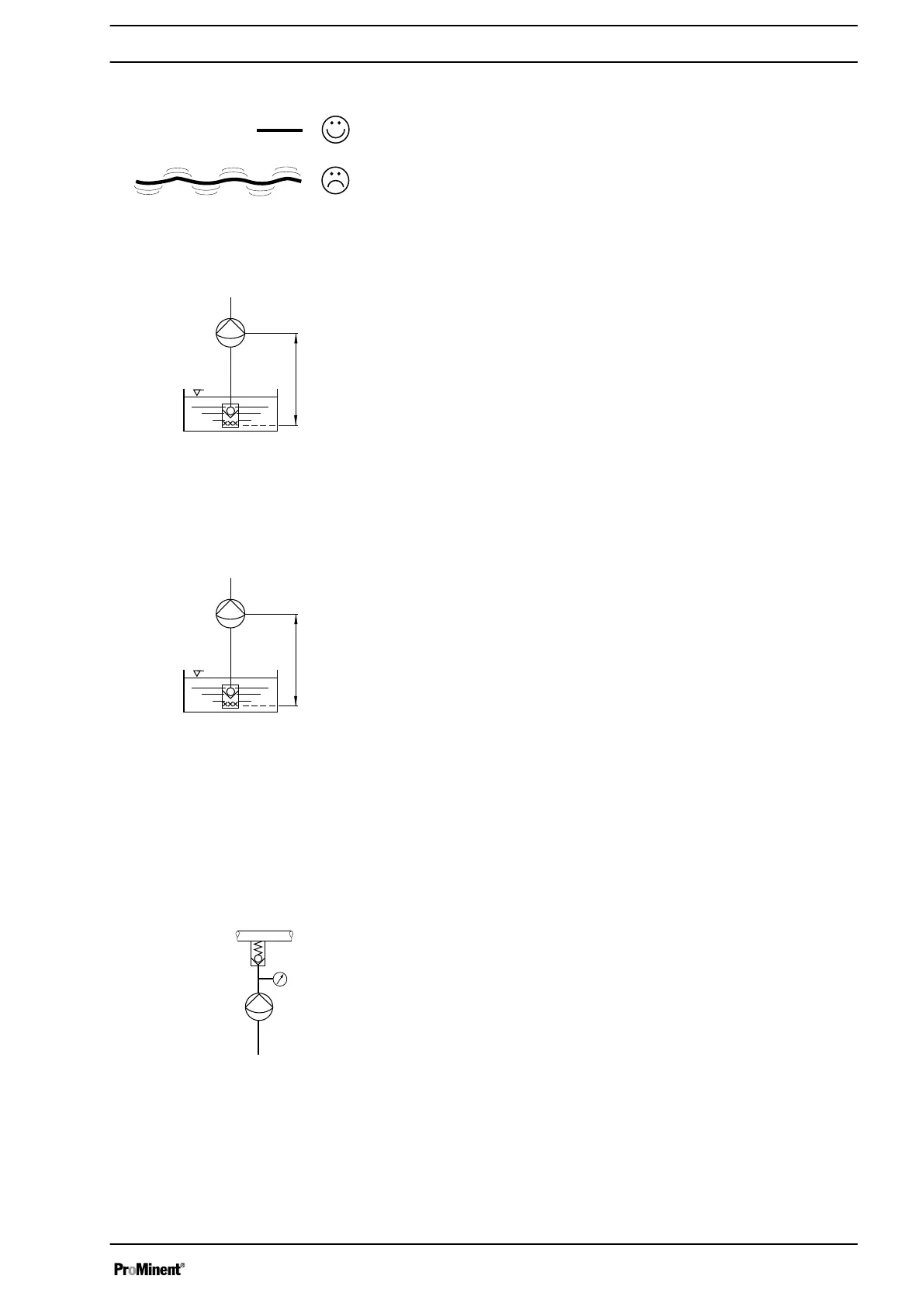

n Install a foot valve at the end of the suction line, in case the

pump is higher than the maximum fluid level in the storage

tank.

n Only shorten the free end of the suction line until the foot valve

is suspended just above the container base.

7.3 Information on the discharge-side installation

n Install a vacuum breaker if the feed chemical may not press

through the metering pump. Metering pumps are not absolutely

leak-tight shut-off units.

n Install the injection valve at the injection point to prevent

unwanted mixing of water and feed chemical in the discharge

line.

Length of suction line

Fig. 7

Height difference, suction side

Fig. 8

Avoid allowing the suction line to run

dry.

Fig. 9

With return from the main line

Fig. 10

Installation, hydraulic

23

Loading...

Loading...