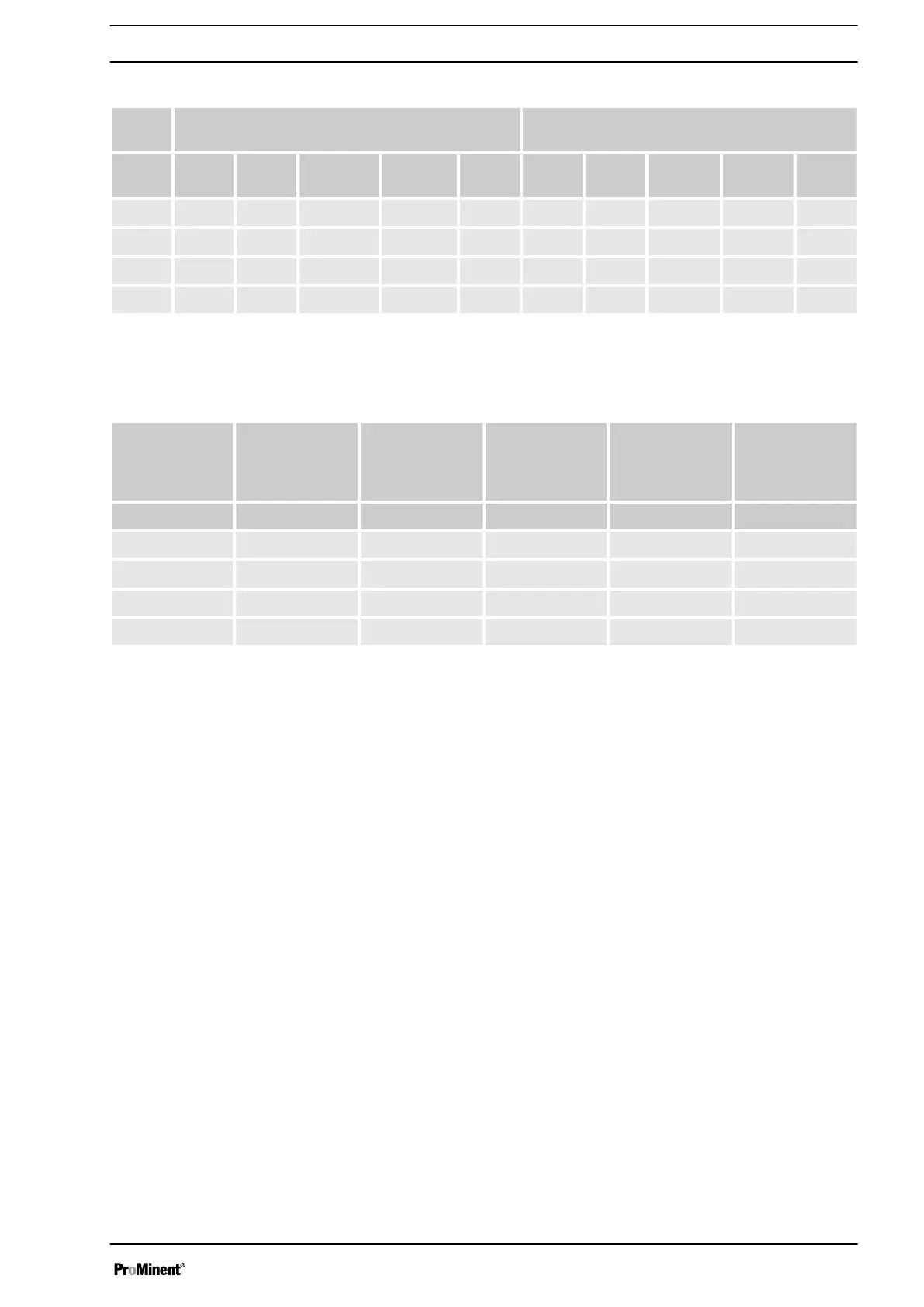

Tab. 9: Metering pumps with self-bleeding dosing head ***

Pump

type

Maximum pump capacity at maximum back

pressure

Maximum pump capacity rate at medium back

pressure

EXBb bar l/h psi gph Ml /

stroke

bar l/h psi gph Ml /

stroke

1601 16 0.66 232 0.174 0.09 - - - - -

1201 12 1.0 274 0.265 0.14 - - - - -

0803 8 2.4 116 0.634 0.33 - - - - -

1002 10 1.8 145 0.476 0.25 - - - - -

*** The given performance data represents guaranteed minimum

values, calculated using water at room temperature

1 gal= 3.78 l

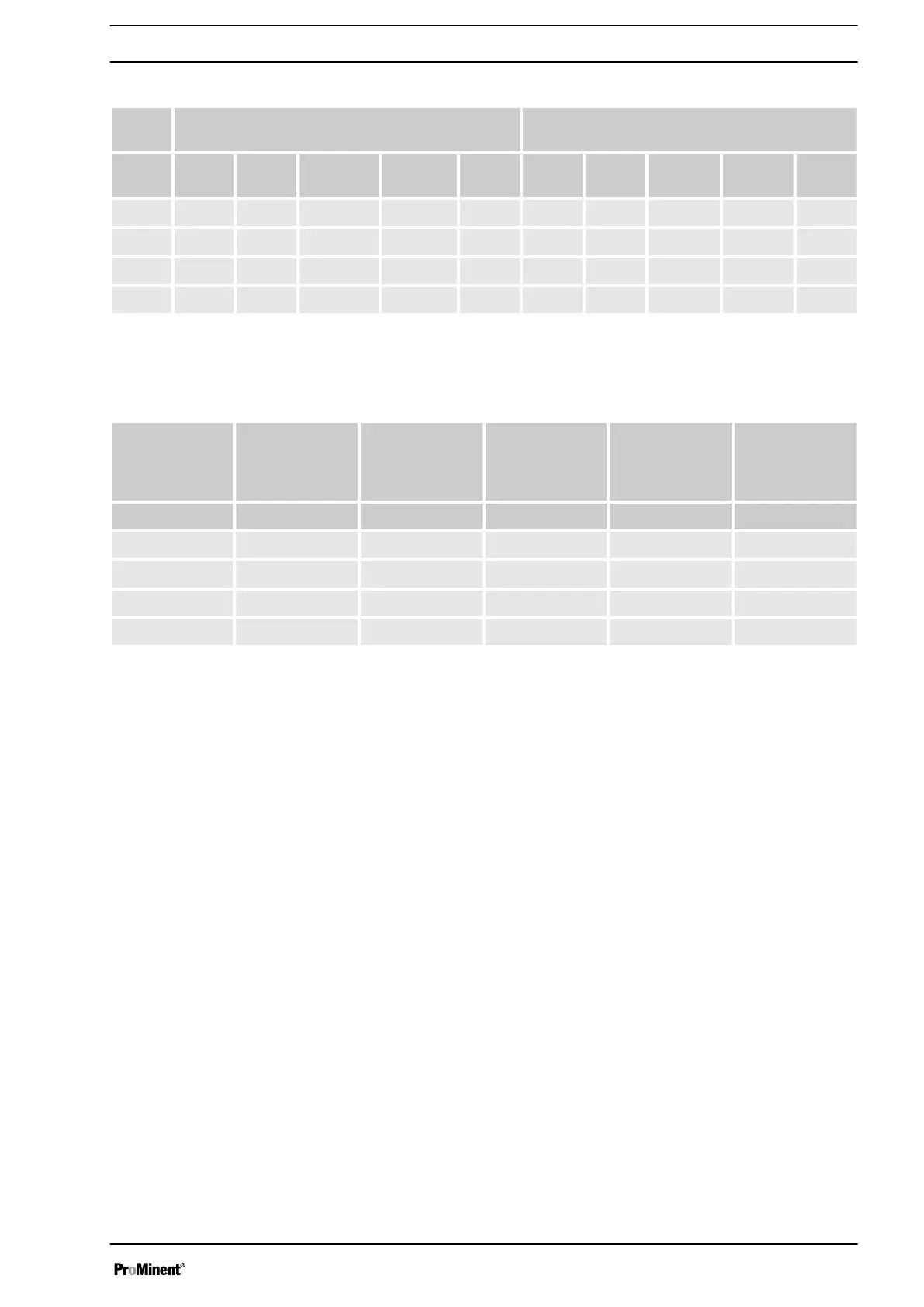

Pump type Stroke rate Connector size

outside dimen‐

sion x inside

diameter

Suction lift* Priming lift** Permissible pri‐

ming pressure,

suction side

EXBb Strokes/min mm m water column m water column bar

1601 120 6x4 - 1.8 0.2

1201 120 6x4 - 2.0 0.2

0803 120 6x4 - 2.8 0.2

1002 120 6x4 - 2.0 0.2

* Suction lift: with filled suction line

** Priming lift: with an empty suction line

14.2 Precision

min.: -5 %, max.: not specified

with max. stroke length and max. back pressure for all material ver‐

sions.

better than ± 2 %

under constant conditions and at least 30% stroke length;

Note the following information:

n All figures refer to dosing measurements with water at 20 °C.

n Constant back pressure, if possible above 1 bar.

n If metering at atmospheric pressure, a back pressure valve

must be used to create a back pressure of at least 1.5 bar

(note the installation examples).

n Wherever possible, lay suction and metering lines on a contin‐

uously rising gradient.

n If the liquid level of the storage tank lies above the pump when

in operating mode, the priming pressure lies against the suc‐

tion side; in this case, the back pressure should be high

enough to ensure a minimum pressure difference of 1.5 bar;

alternatively, use a back pressure valve or a spring-loaded

injection valve with corresponding priming pressure.

Technical data

49

Loading...

Loading...