LIZARD

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

11

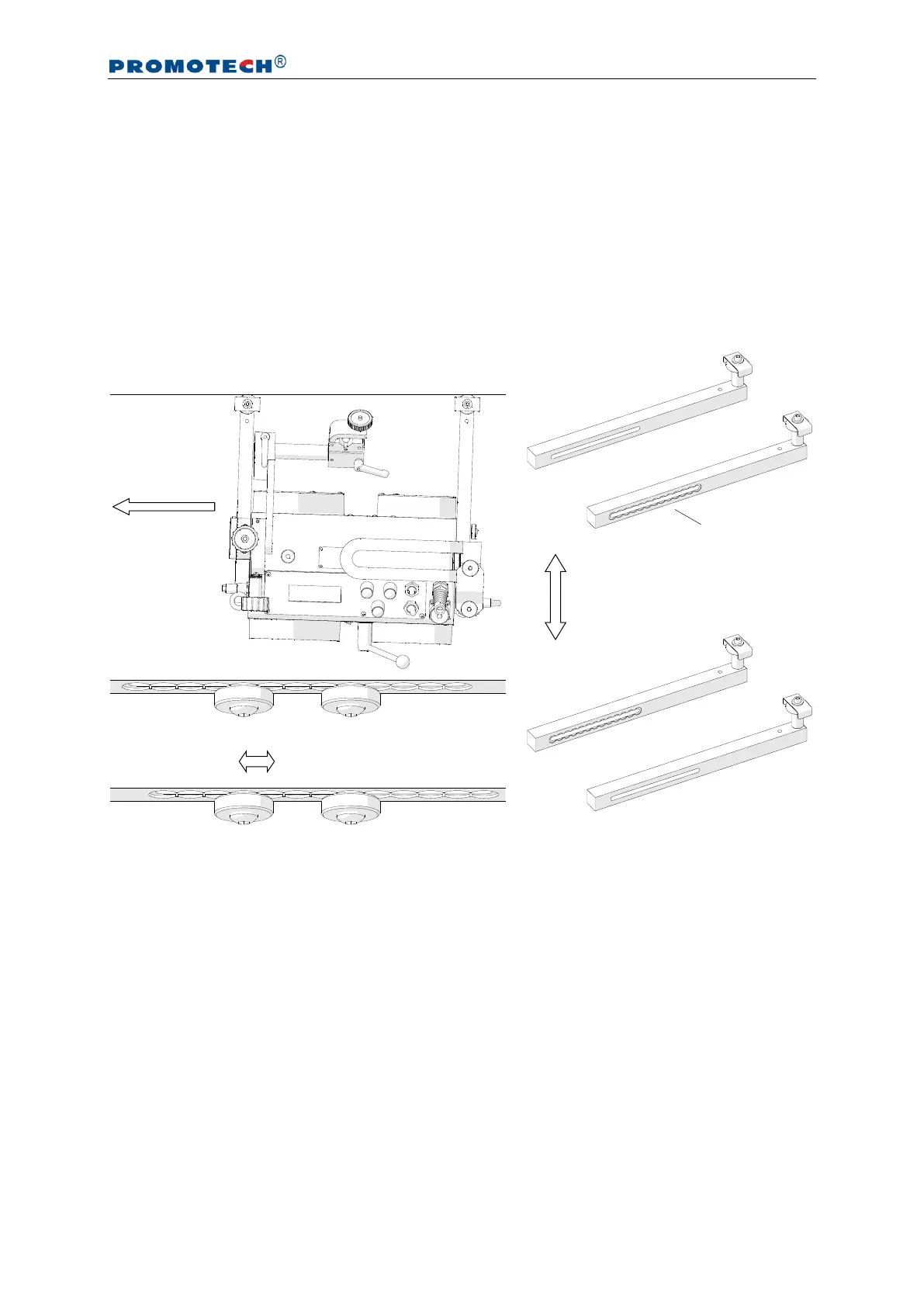

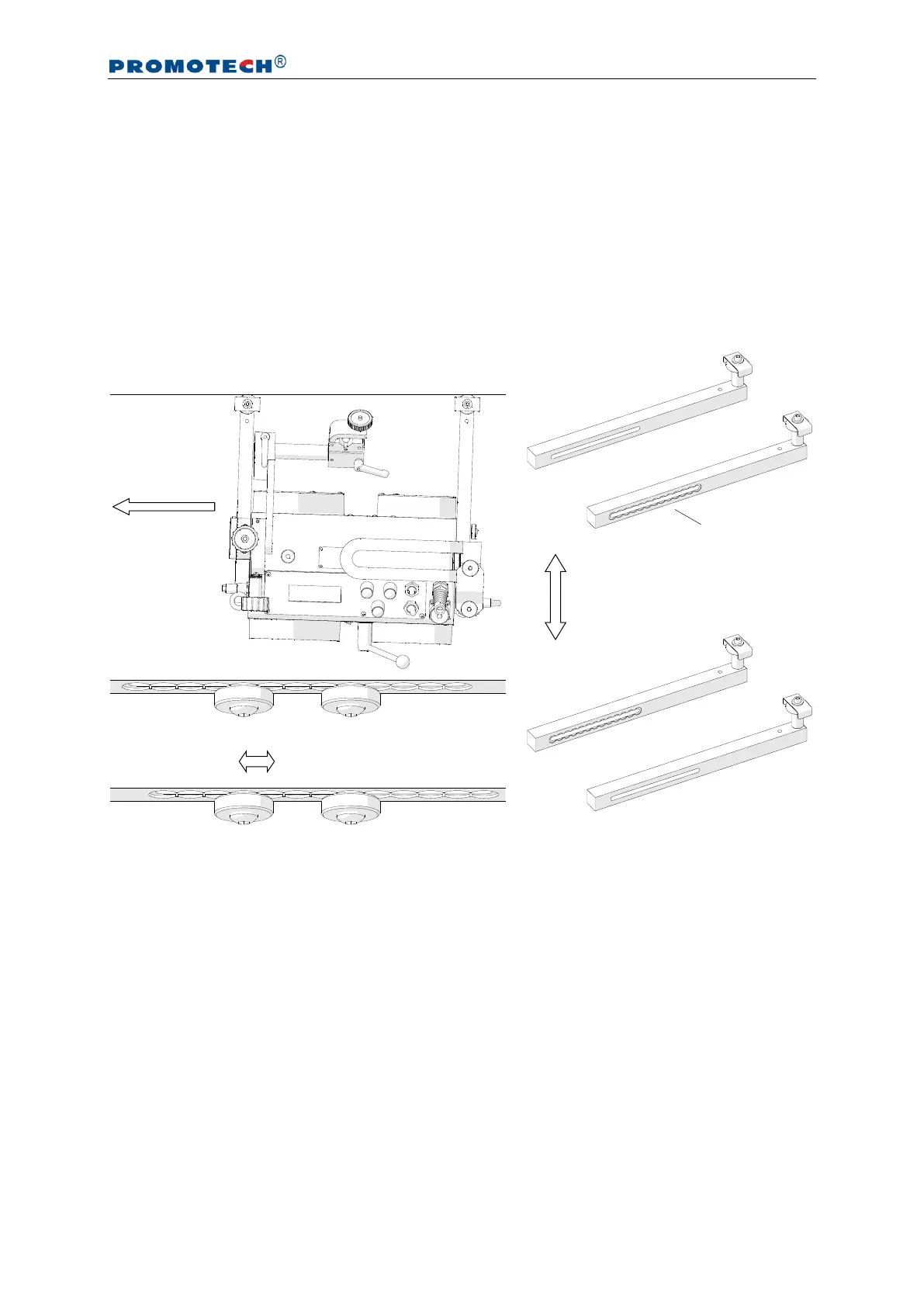

3.3. Positioning at the worksite

The guide arms must be positioned so that the carriage is in constant contact with the

workpiece. They can be set by a constant step (interval adjustment), or continuously

after they are swapped (continuous adjustment). To set them properly when the carriage

travels to the left, use the 4 mm hex wrench to loosen the screws securing the right

guide arm, move out the right arm about 10 mm (0.4’’) or one groove more than the left

arm (Fig. 5), and then retighten the screws.

Fig. 5. Proper positioning of the guide arms

Switch the magnet ON/OFF lever from left (‘O’) to right (‘I’), which will change the

clamping force from minimum to maximum. Loosen the levers to adjust the position

and angle of the torch, and set the torch position precisely using two knobs located at

the cross slide. When operating at heights, attach a safety line to the lug to prevent

possible injury if the carriage loses the clamping. The safety line is not included in

standard equipment.

Swap the guide arms

to change between

methods of adjustment

Moving out the right arm

by one groove

Loading...

Loading...