ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

13

3 Technical Data and Structure

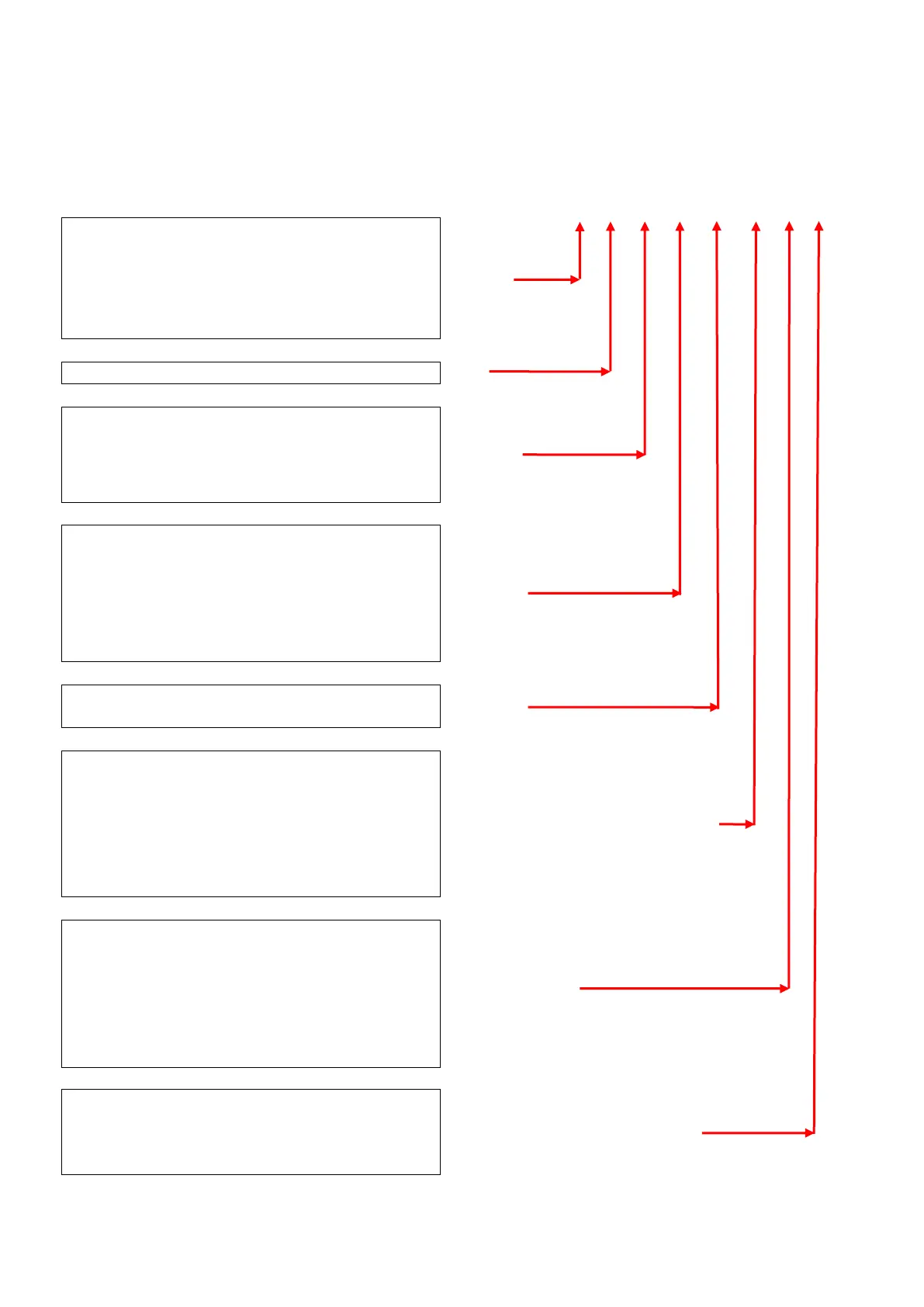

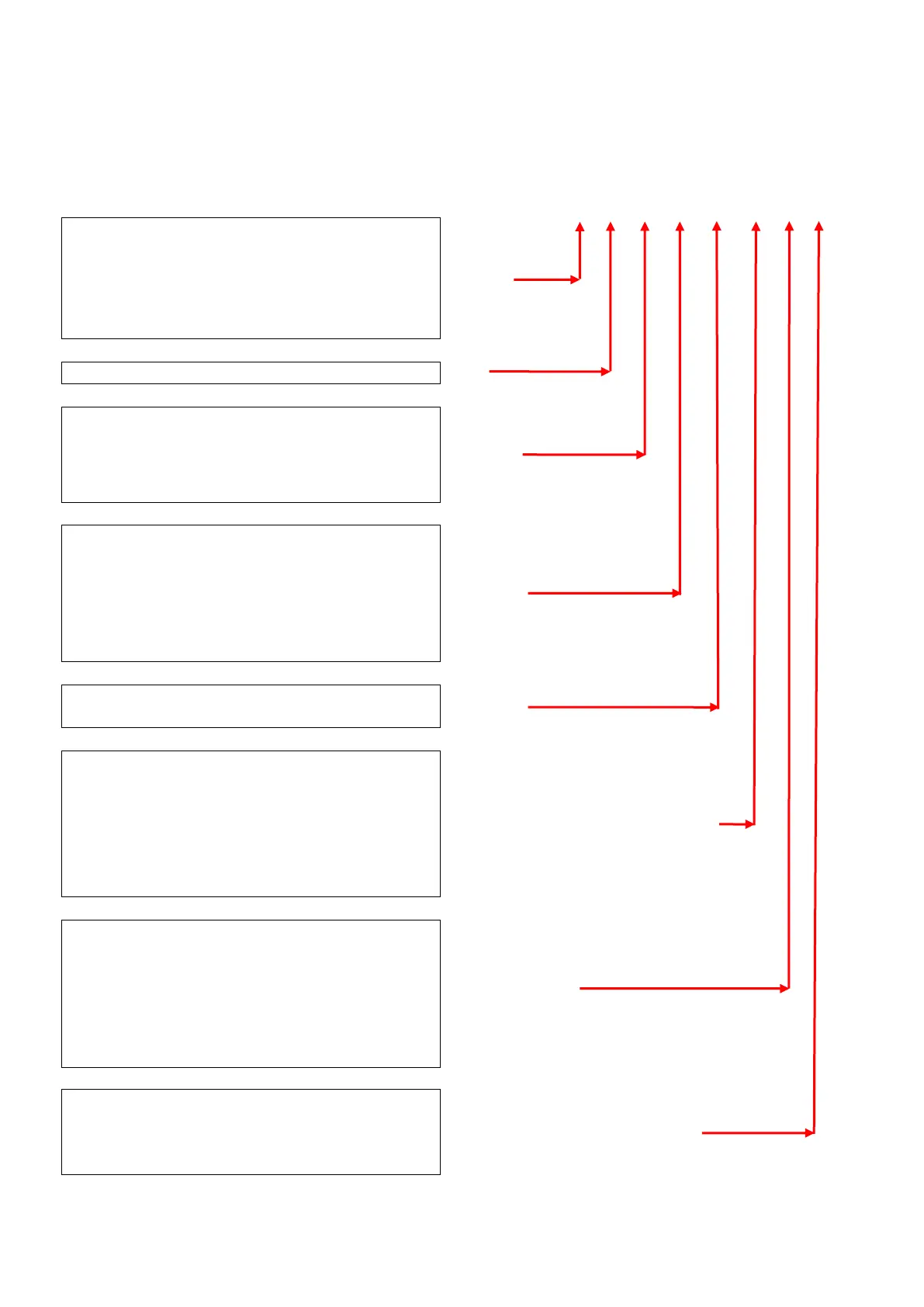

3.1 Conveyor / station designation key

Conveyor / station designation key

FGG = Conveyors for gravimetric dosing unit

(without floor flap)

FG3- = Conveyor installed from ∅315 to ∅200

FG 2K = 2-component conveyor/station

2 = 200 (∅ conveyed goods container 200 mm)

0 = Conveyor with blower, central filter installed

2 = Conveyor station with filter cartridge cleaning with

circulating air with microcontroller control system for

separate fan station

1 = Cloth filter without cleaning

4 = Cloth filter with cleaning (compressed air)

5 = Filter element 0.2 m

2

with cleaning (circulating or

compressed air)

6 = Filter element 1.5 m

2

with cleaning (circulating or

compressed air)

0 = For separately installed blower station

1 = Installed blower (50/60 Hz) 0.8 kW

Material conveyed goods container

0 = Without controls / connection box / terminal box

1 = Microcontroller control system

A = Murr plug connection- (custom)

B = M12-Y plug connection- (custom)

Plug connection system - design

C = Phönix plug connection

HG2 = Hot granulate max. 150° C

(Normal temperature max. 80°C)

Loading...

Loading...