3 - Logging Options

3.3 Dynamic Data Logging

When spraying conventionally (i.e. not VRT mode), you have an option to generate a

full spray application record, logging rate and other parameters (e.g. "tags") in real

time, attributing this data to a specific location. The associated "Dynamic Logging" file

is saved onto the Data Card Module and can subsequently be viewed in PLOT/PLAN.

An RDS Data Card Module and a GPS receiver must be connected.

3.3.1 Start recording a Dynamic Job

1 Press the LOG key.

The screen will display the current logging status, the number of jobs (job

summaries) stored in memory, and the status of the PCMCIA card if found (fig. 17). If

the module is not detected the message "NO MODULE FOUND" is displayed. When

successfully connected, the icon appears at the top of the screen.

2 Press the START key. The JOB STARTUPpage is displayed (fig.17)

3 Select the logging option "LOG TREATMENT".

4 When prompted, enter the FARM NUMBER and FIELD NUMBER reference. The

"EXTENDED DATA FUNCTIONS" page is then displayed. If you don't wish to

programme any extended functions. then press . .

5 If you want to programme extended functions, refer to section 3.2.5.

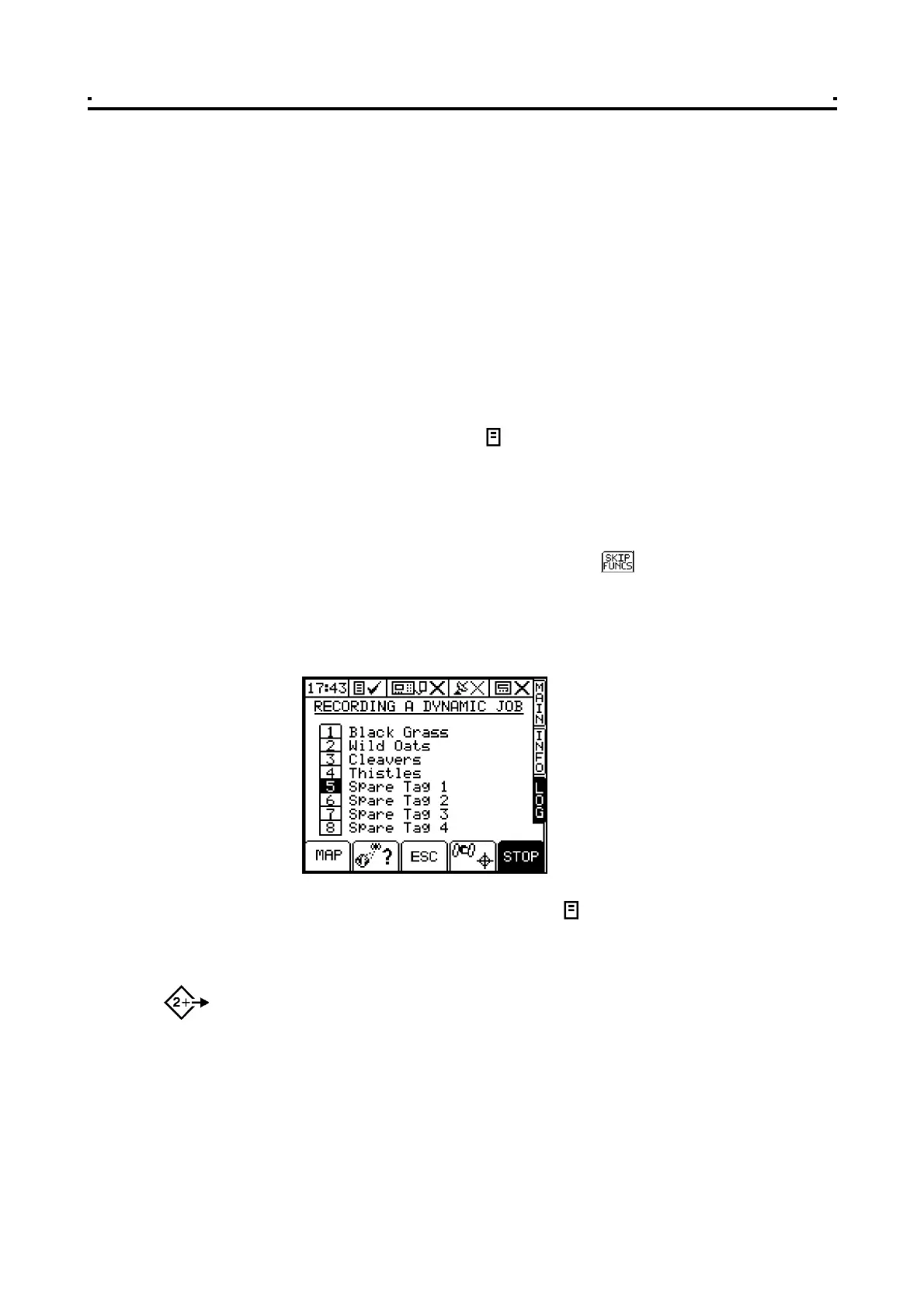

The screen will display "NEGOTIATING FILE STORAGE - JOB NUMBER #" as it

creates the dynamic log file on the data module. Once the plan is loaded, the

"RECORDING A DYNAMIC JOB" page appears, and displays the tag list (fig. 24).

While dynamic logging is in progress, the icon appears animated at the top of the

screen.

6 You can at any time apply the Tag functions to log features in the field. Please refer

to section 3.2.4 overleaf.

NOTE: If more than one machine is enabled, the summary job record will include data for

each machine.

3.3.2 Stop recording a Dynamic Job

To stop running a job, simply press the "STOP" key on the LOG screen. The job

summary is appended to the dynamic log file on the data module, and saved to the

internal memory.

Figure 24

Dynamic Logging

Loading...

Loading...