Installation — Wiring | 27

CONNECTING MULTIPLE LOADS

CAUTION: Do not use the Battery Monitor outside the recommendations below. Exceeding the

recommendations could damage the Battery Monitor and/or other equipment installed in the system.

The installer is responsible for ensuring the correct bolt size and Ground cable size is used.

The Battery Monitor is capable of connecting multiple loads to the Ground (GND

) terminal. Depending on

your system setup, you may need to use the supplied Alternative Terminal Bolt (M10×20 mm). Refer to the

table below to determine if this bolt is required. The lugs belonging to circuits with the highest currents should

be closest to the Battery Monitor terminal.

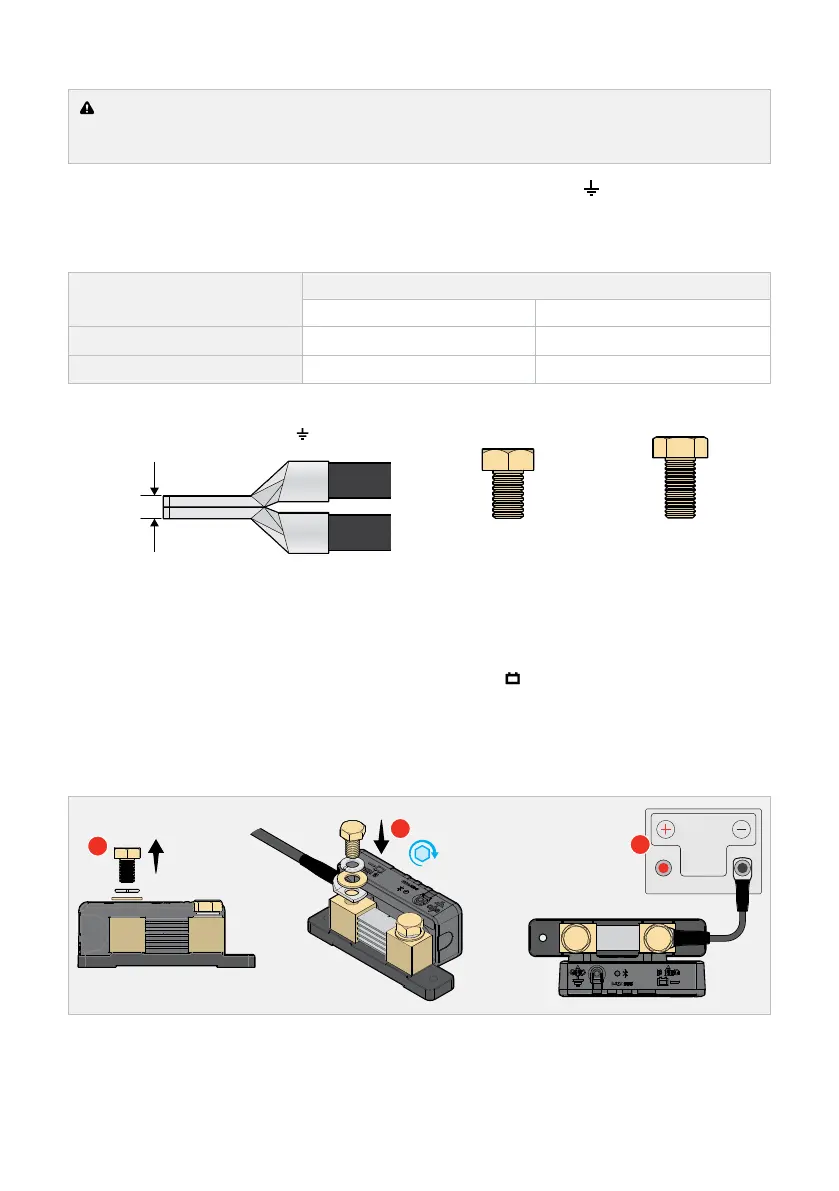

Bolt Size (supplied)

Combined Thickness of Lug Tongues

Minimum Maximum

Standard M10×16 mm – 4 mm (5/32")

Alternative M10×20 mm 4 mm (5/32") 8 mm (5/16")

Lug side view

Combined

tongue

thickness

4 mm (5/32")

use Standard Bolt

(M10×16 mm)

>

4 to 8 mm (5/32 to 5/16")

use Alternative Bolt

(M10×20 mm)

Lug thickness for Ground (GND ) Terminal

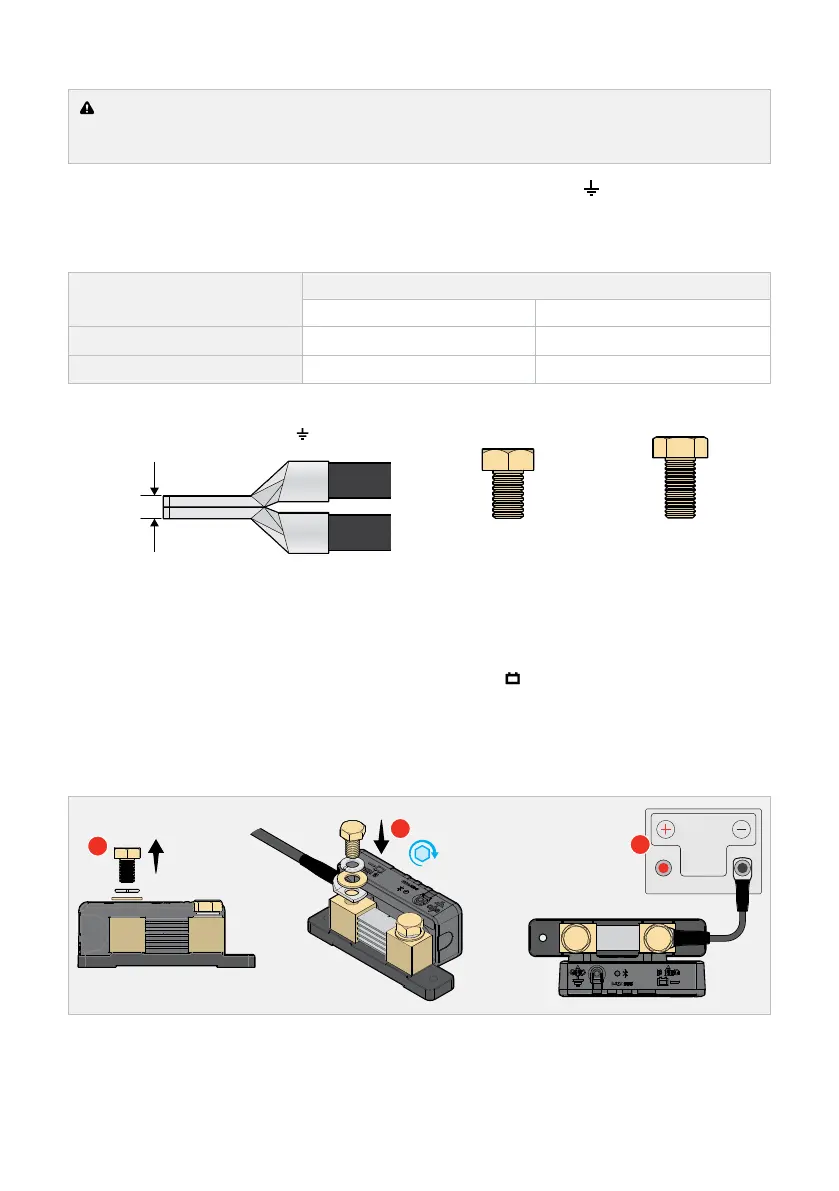

BATTERY NEGATIVE (B NEG) CABLE CONNECTION

Remove the M10 Bolt and washers from the Battery Negative (B NEG –) terminal (1). Then align the lug stud

hole with the terminal and fasten using the at washer, spring washer and bolt (2). Torque to 20 N·m (14.7 lbf·ft).

Connect the Battery Negative cable to the auxiliary battery negative (–) terminal using appropriate fasteners (3).

NOTE: The Battery Negative cable should not exceed 1 m (3'3") to minimise voltage drop between the

Battery Monitor and auxiliary battery.

Auxiliary

Battery

1

2

3

20N·m ±10%

14.7lbf·ft ±10%

Loading...

Loading...