The function block monitors

the speed of a device, generating the Zero to 1 (TRUE)

output when the speed is lower than a selected value. In

addition, it generates the Over = 0 (FALSE) output if the

measured speed exceeds a predetermined threshold.

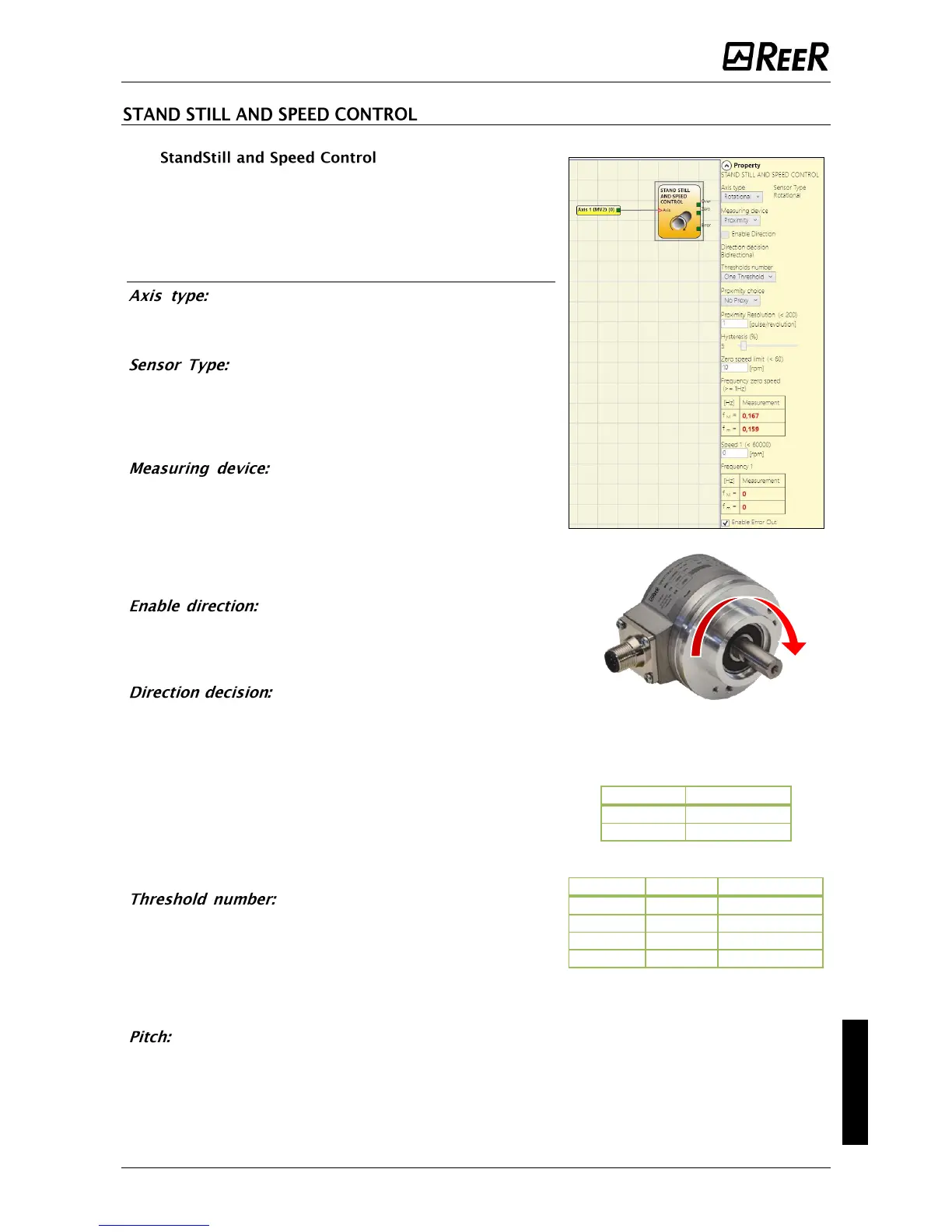

Parameters

It defines the type of axis controlled by the

device. It will be Linear in the case of a translation and will

be Rotary in the case of motion around an axis.

In the event that the previous parameter is

Linear, the Sensor Type defines the type of sensor

connected to the module inputs. It can be Rotary (e.g. shaft

encoder) or Linear (e.g. optical array). This choice allows to

define the following parameters.

It defines the type of sensor(s) used.

The possible choices are:

- Encoder

- Proximity

- Encoder+Proximity

- Proximity1+ Proximity2

- Encoder1+ Encoder2

Enabling this parameter, the DIR output

is enabled on the function block. This output will be 1

(TRUE) when the axis rotates Counterclockwise and will be

0 (FALSE) when the axis rotates Clockwise.

It defines the direction of rotation for

which the set thresholds are made active. The possible

choices are:

- Bidirectional

- Clockwise

- Counterclockwise

If Bidirectional is selected, the excess of the set threshold

is detected whether the axis rotates clockwise or

counterclockwise. Selecting Clockwise or

Counterclockwise, this is detected only when the axis

rotates in the selected direction.

It allows you to enter the number of

thresholds for the maximum value of speed. Changing this

value will increase/decrease the number of thresholds that

can be entered from a minimum of 1 to a maximum of 4.

In the case of thresholds greater than 1, the input pins for

the selection of the specific threshold will appear in the

lower part of the function block.

If the Axis Type chosen was linear, this field allows

you to enter the sensor pitch to obtain a conversion

between sensor revolutions and distance travelled.

Loading...

Loading...