8

REMKO GPS series

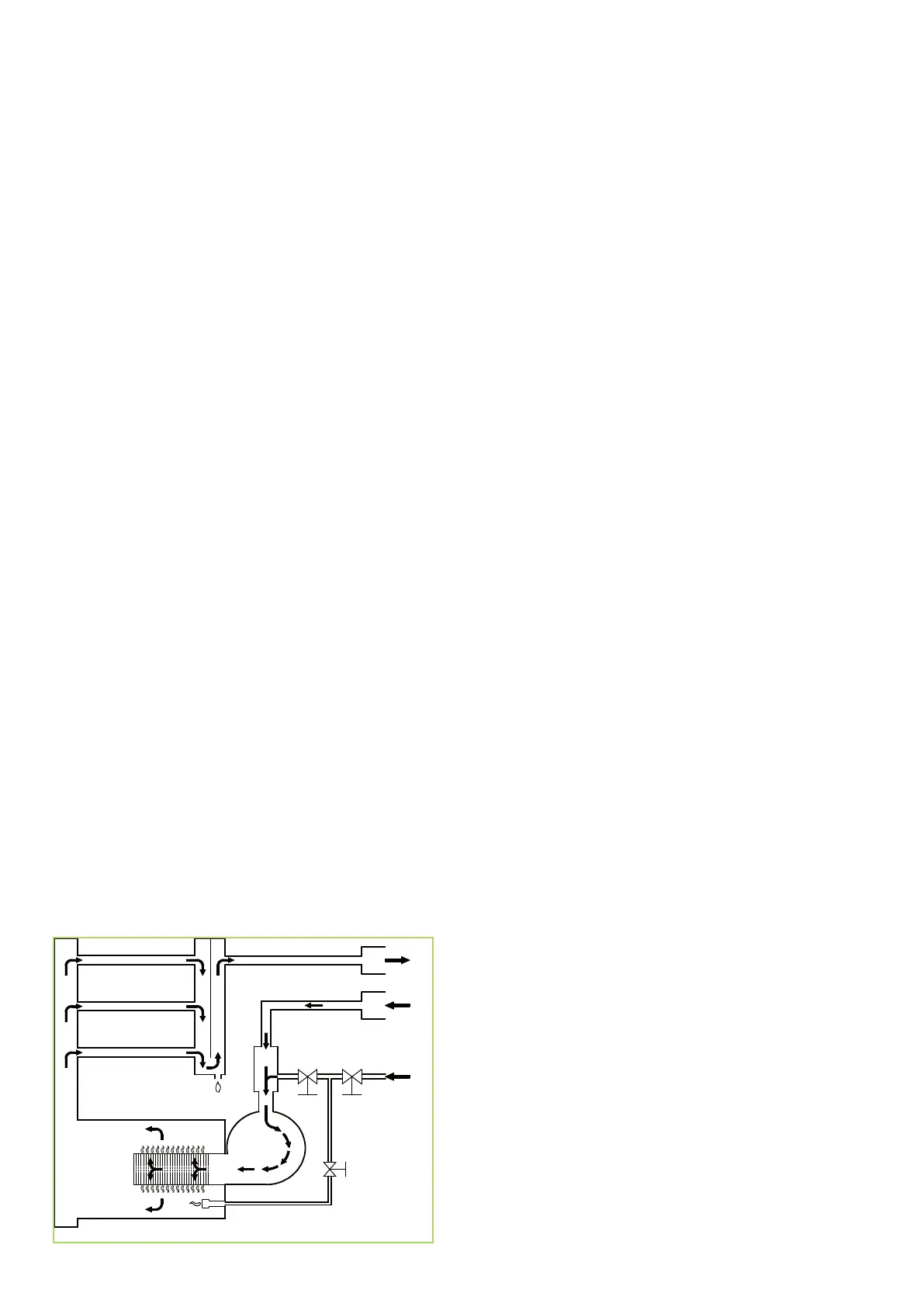

Cycle of operation

The units from the GPS range are fully-automatic hot

air heaters, which are equipped with an electronic

device with self-testing. This guarantees a high degree

of reliability and safety.

Burner operation

The burner is ignited when the following

preconditions are fulfilled:

■

The unit is supplied with power and is not in a fault

shut-down state (lock-out)

■

The gas supply valve is open

■

The toggle switch on the control panel is switched

to the “I=Winter” position

■

The thermostat contact is closed

■

The contact between terminal 34 and 35

on the GPS board is closed

Under these conditions, the burner fan starts

immediately. After the pre-flushing process is

complete, the flame is ignited with an ignition

output that is 30 % of the maximum output. After

subsequently waiting for the stabilisation phase to

pass, the burner runs up to maximum output.

If the flame cannot be ignited then 4 further

ignition attempts take place. With the fifth ignition

attempt, the GPS board triggers a fault shut-down.

If the burner ignites, the cooling fan starts up after

30 seconds and conveys the warm air into the room.

In order to switch the hot air heater off, the switch

on the control panel must be set to the “0” position.

It is prohibited to switch off the unit by disconnecting

the power supply. This process must be used

exclusively in emergencies. With an instructed switch-

off of the hot air heater, the burner fan continues

to operate for a further 90 seconds, in order to flush

the burner chamber of flue gases. The cooling fan

runs on for 120 seconds after the switch-off, to

ensure that the heat exchanger “cool down” takes

place. If the cool down process is not completed then

this reduces the service life of the heat exchanger and

therefore also invalidates the guarantee. Furthermore,

the safety thermostat may also be triggered and

necessitate a manual reset.

If, during the cool down phase, a new heating request

is issued then the unit waits until the cooling fan has

switched off, performs a reset and then starts a new

heating cycle.

Efficiency

The advantages of the units lie in the 2-stage mode

of operation, meaning the heat output created and

thus the gas flow (consumption of fuel) are changed

corresponding to the heating stage.

With a reduced heat requirement of the room,

the fan-assisted heater consumes less fuel, whereby

its efficiency is increased by up to 94%.

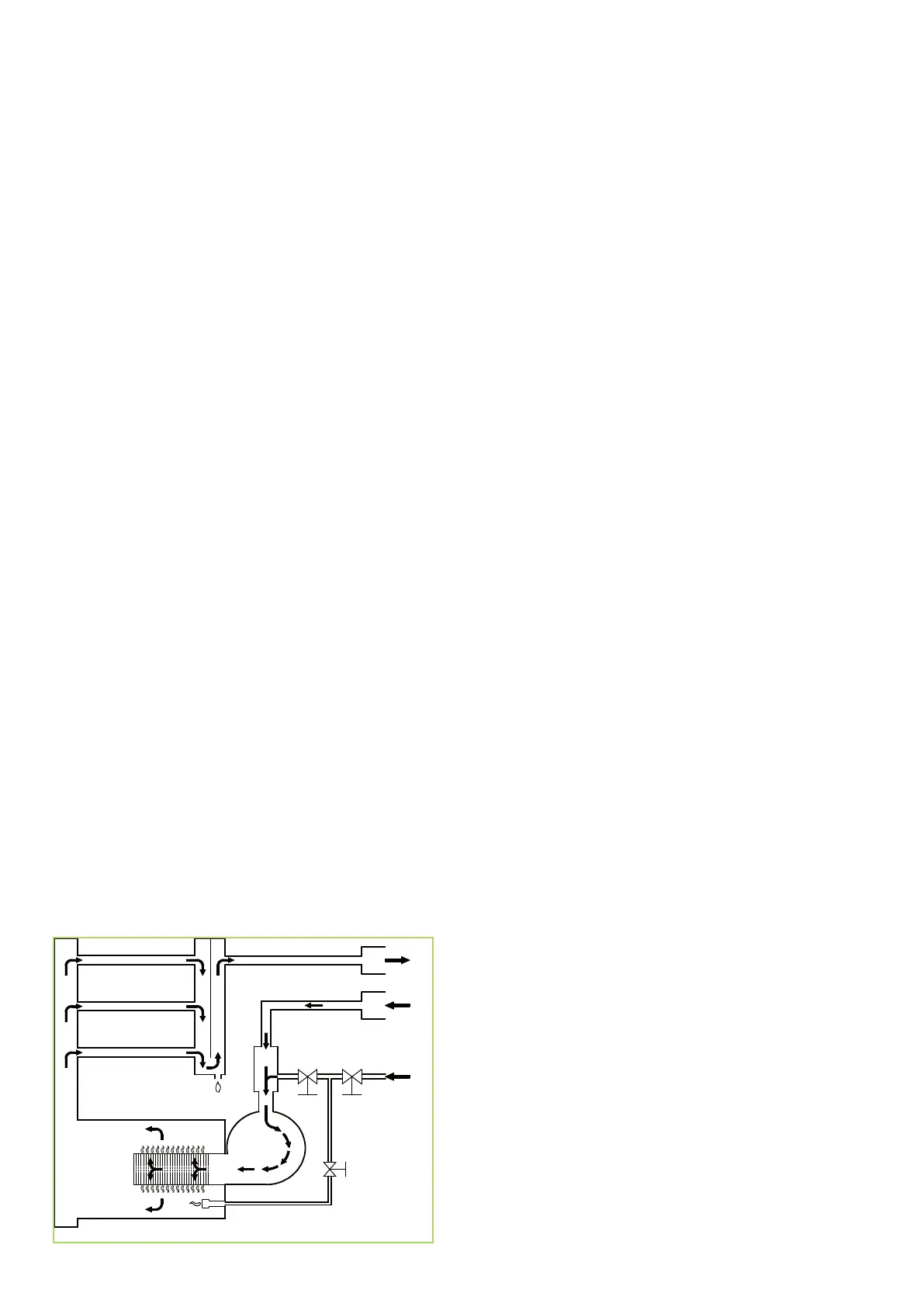

Intrinsic safety:

The increase in efficiency with minimum output is

achieved through the use of a modern air/gas mixture

technology and the simultaneous flow rate regulation

of combustion air and gas.

This technology increases the safety of the unit,

because the gas valve feeds the fuel depending on

the amount of air in accordance with its factory

settings.

Unlike atmospheric burners, the CO

2

content

remains the same through the entire operating range

and allows an increase in efficiency with reduction

of the heat output.

With no combustion air, the valve does not release

gas.

With reduction of the combustion air, the gas valve

automatically reduces the amount of gas and keeps

the combustion parameters at an optimal level.

Luft

Abgase

Gas

EV1EV2

EVP

HW080909

Flue gases

Air

Gas

Loading...

Loading...