39

Alignment tolerances

The tolerances to which a tool can be set are

dependent on the parallelism of the laser beam

to the machine axes.

Tool setting applications

Over a span of 100 mm (3.94 in), the following

alignment accuracies are easily achievable:

Spindle axis (P2 – P1) = ≤10 µm (0.39 µin)

Radial axis (P2 – P1) = ≤1 mm (0.39 in).

These values are sufficient for the majority of

tool setting applications.

Tool breakage detection applications

Over a span of 100 mm (3.94 in), the following

alignment accuracies are easily achievable:

Spindle axis (P2 – P1) = ≤0.2 mm (0.0079 in)

Radial axis (P2 – P1) = ≤1 mm (0.39 in).

These values are sufficient for the majority of

tool breakage applications.

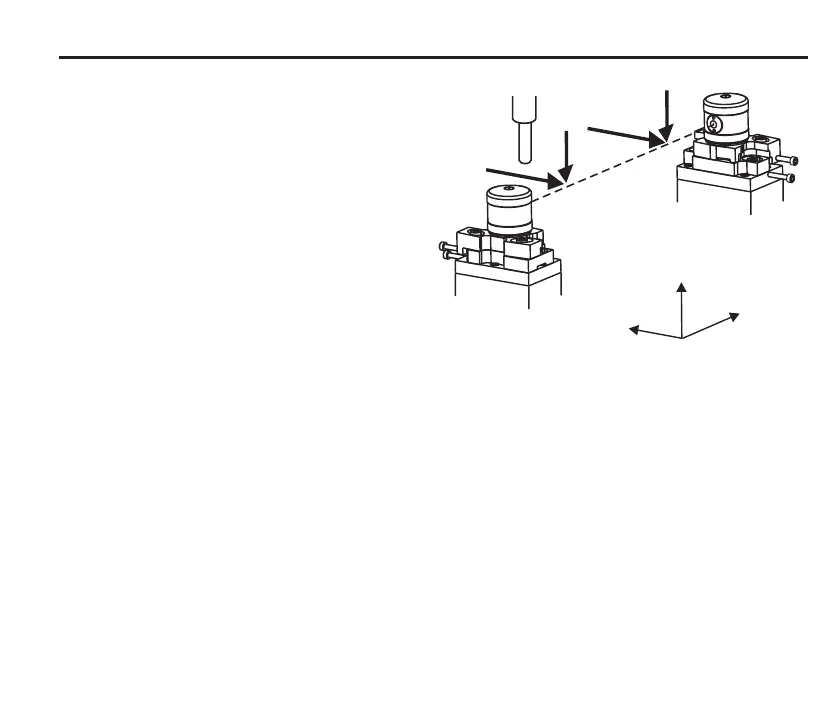

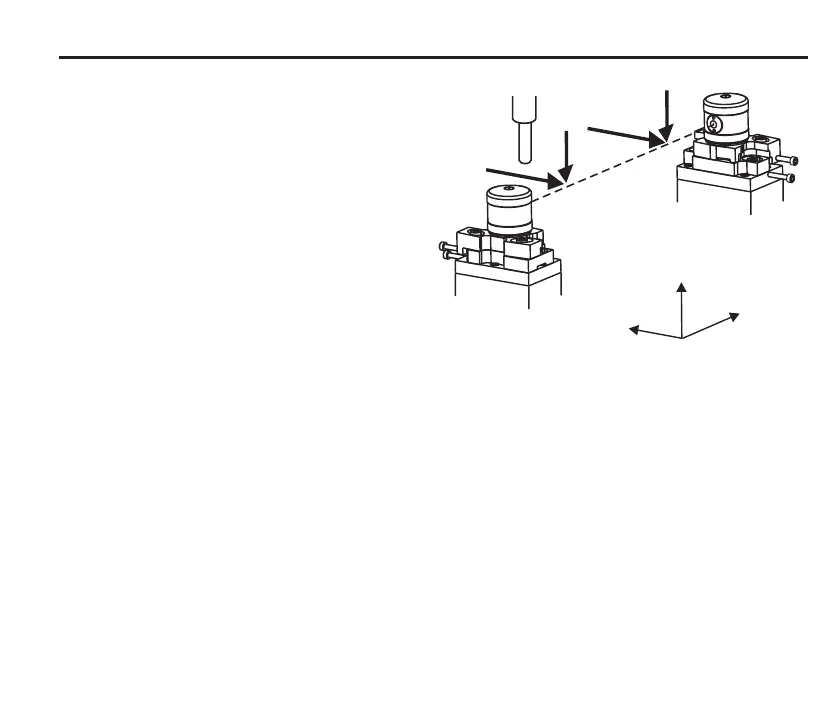

System alignment tolerances

P1

P2

Spindle axis

Beam

axis

Radial

axis

Loading...

Loading...