weight of 2 100 g can be additionally mounted. The best results are generally achieved with

amplitudes from 1.0 to 1.5 mm.

Example 1:

By using the add-on mass, the maximum attainable amplitude amounts 3 mm. Without the add-

on mass, the maximum attainable amplitude would only be ~ 2.5 mm.

7.6 Time

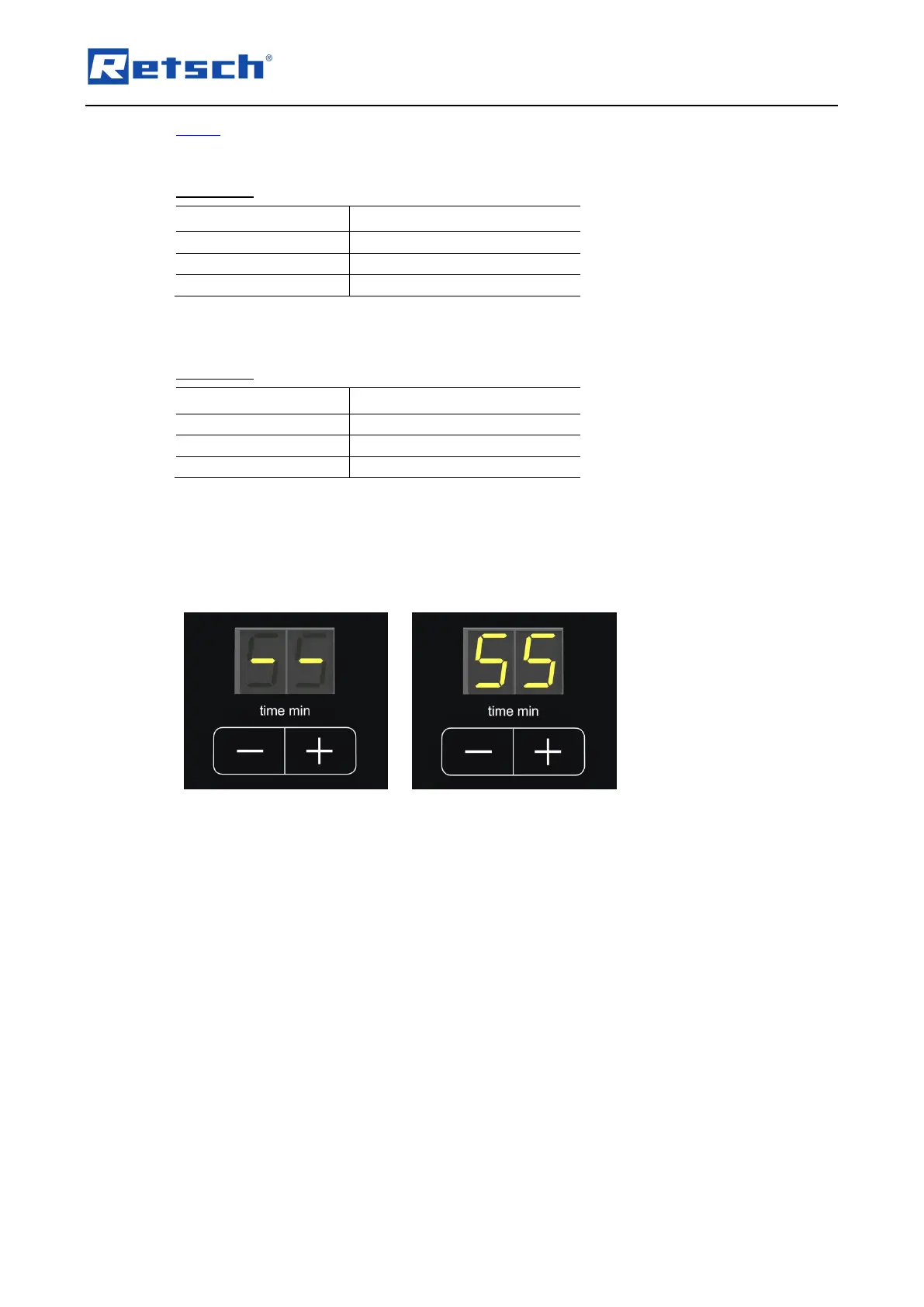

The AS 200 control can be operated either in continuous operation or for a certain time between

1 and 99 minutes. When the device is switched on, the last used setting is displayed.

Press the "+" or "-" button of the time display (H5) to set the desired process time.

Press and hold the "+" or "-" button to extend or reduce the process time in steps of ten

minutes, respectively.

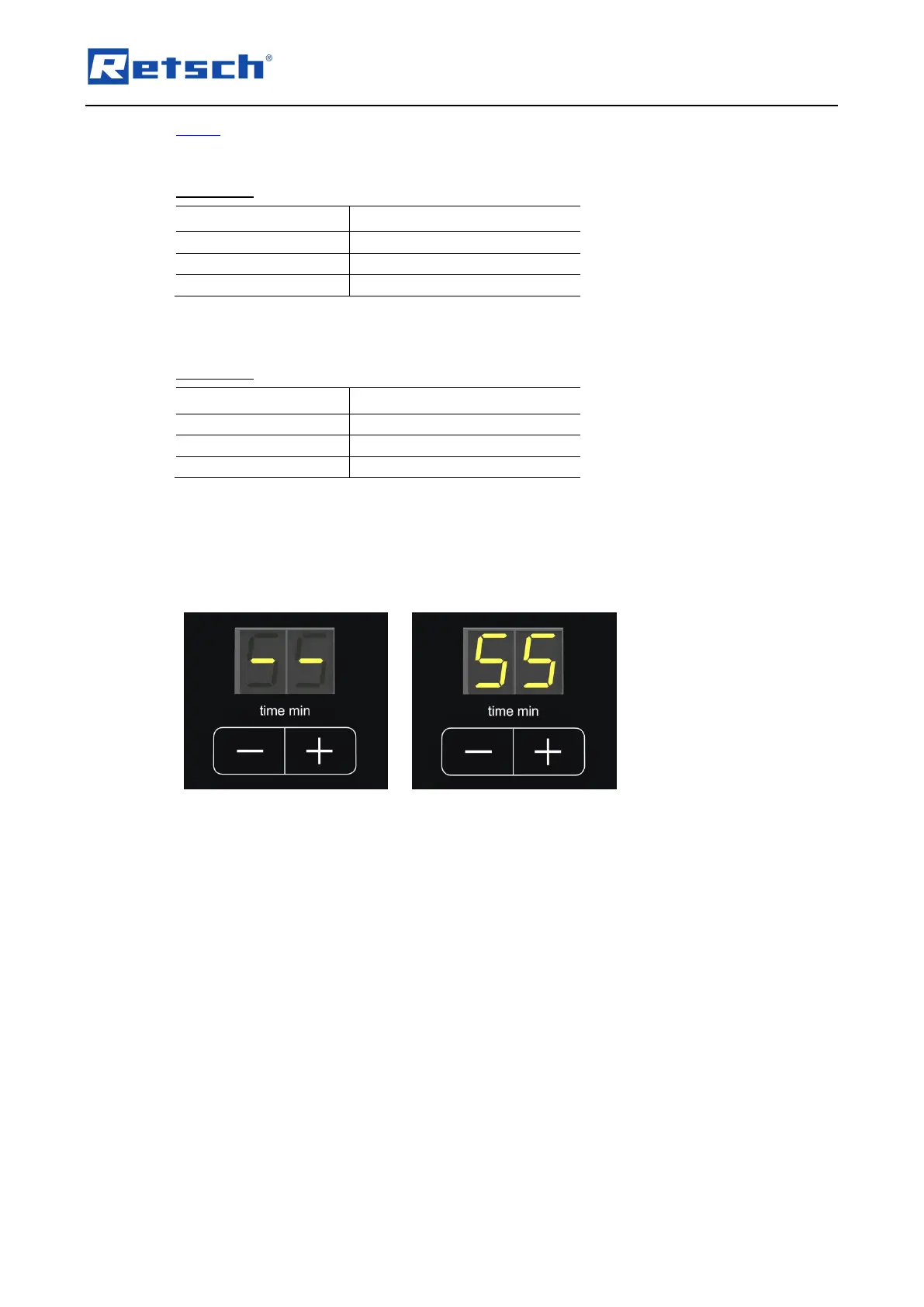

To change to the continuous operation, fall below the duration of 1 min by pressing the "-"

button, or exceed the duration of 99 min by pressing the "+" button. The time display (H5)

now indicates " ".

The process time can also be changed during operation by pressing the "+" or "-" button.

7.7 Optimisation of Time and Amplitude

The settings of the optimum sieving time and amplitude depend on the sample material. These

settings have a substantial influence on the measurement result. Generally, national and

international standards, internal regulations and standards provide detailed information on

product-specific sieve analyses and the associated sieving parameters. If such basic

Loading...

Loading...