23

INSTALLATION

− Switch the main power supply to ON

− Use the PB inner display to enter the appliance conguration

menu and change the parameter #98 from ‘’17’’ to ‘’18’’. Follow

this path: menu-> setting ->

appliance

-> conguration ->

password -> boiler -> managing -> 98

appliance

setting

(from ‘’17’’ to ‘’18’’) -> conguration conrmed (‘’yes’’).

Repeat the same sequence for each dependent module.

− Adjust the O2 parameter as explained in next chapter

− Afx the gas type label from the gas conversion kit to the

appliance.

− Repeat above process for all heat exchangers.

Additional parts (such as a high voltage ignition transformer) may

be required for reliable ignition of the propane. Please consult the

Riello factory prior to all conversions from natural gas to propane

4.12.5 Adjusting and Setting O2 Limits

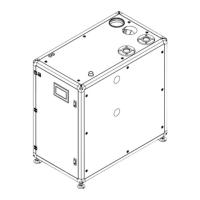

− Insert a combustion analyzer probe into the test port

shown in Fig. 17

− Go to the Touchscreen and access the Module screen (as

described on “6.3.4 Module Screen” page 37) relevant to the

module under analysis;

− Press “MODULE TEST” button;

− Press “HIGH POWER” button.

Wait 2 or 3 minutes to reach steady state conditions and record

the O

2 value.

Test port of

the module

Fig. 17

Test Port for Combustion Analysis (available on each

individual heat exchanger)

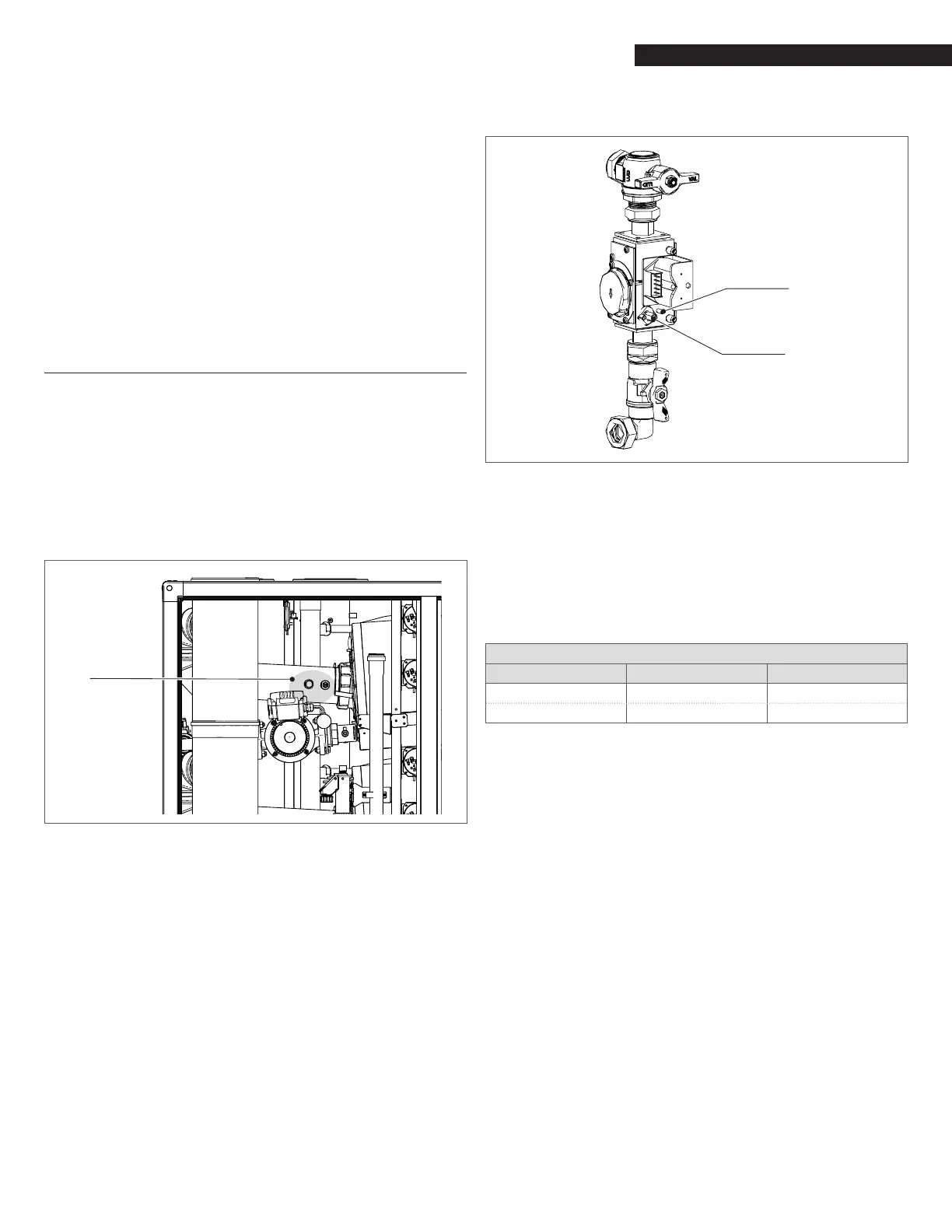

To adjust the O2 value at high-re turn the screw “A” (rotate

counter-clockwise to decrease O

2) shown in Fig. 18. An allen type

wrench is necessary for this adjustment.

Verify that the value of O

2 is stable and within the rangeindicated in

the following table (be careful to make small changes and conrm

that the value is stable before making additional adjustment).

Press “LOW POWER”: the fan will run at the minimum speed.

Fig. 18

O

2

Adjustment

To adjust the O2 value at the minimum input, turn the screw “B”

(rotate clockwise to decrease O

2) shown in Fig. 18.

Verify that the value of O

2 is stable and within the range indicated in

the following table (be careful to make small changes and conrm

that the value is stable before making additional adjustment).

Press “Reset” and the boiler return to the “stand by” mode.

Press “Reset” to return the boiler to standby mode.

Repeat above process for all heat exchangers.

Array Combustion Values

Gas Type Max. Fire O

2% Min. Fire O2%

Natural Gas 4.2 – 5.8 4.2 – 5.8

LP Gas 5.0 – 5.6 5.0 – 5.6

Loading...

Loading...