37

OPERATION

− Home button: move back to the R screen;

− Performance button: move to the Performance screen of

the cascade;

− Stats button: not active;

− Errors button: move to the Errors screen;

− Service button: move to Service screen;

− Settings button: move to Settings screen;

− Back button: move to the previous screen.

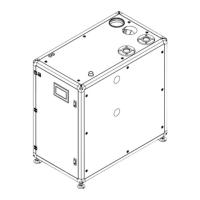

6.3.3 Boiler Screen

Through this screen, the following actions can be performed:

− Check the status of the modules (ON, OFF, in error);

− See the current supply temperature at the boiler header;

− Access the Module screen of the desired module, by

touching it on the screen;

Use the side buttons to perform the actions listed below:

− Home button: move back to the R screen;

− Performance button: move to the Performance screen of

the boiler;

− Stats button: not active;

− Errors button: move to the Errors screen;

− Service button: move to Service screen;

− LWCO TEST button: carry out the Low Water Cut Off

functionality test;

− Back button: move to the previous screen.

Fig. 61

Boiler Screen

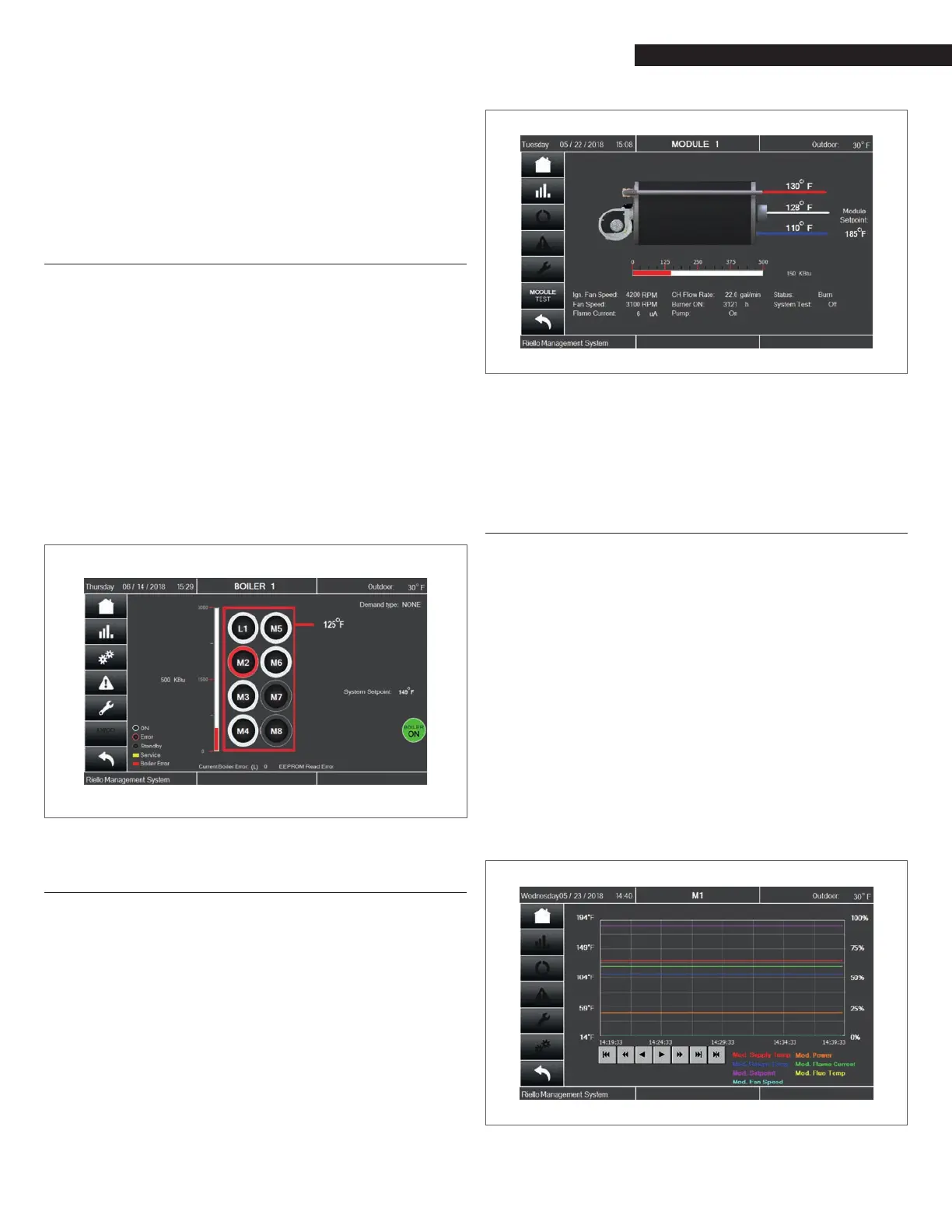

6.3.4 Module Screen

Through this screen, the following actions can be performed:

− See the current value of many parameters: water supply

& return temperature, ue temperature, water owrate,

fan speed, ame rod ionization current, burner and pump

status, any error status or service required;

Use the side buttons to perform the actions listed below:

− Home button: move back to the R screen;

− Performance button: move to the Performance screen of

the module;

− Stats button: not active;

− Errors button: move to the Errors screen;

− Service button: move to Service screen;

− MODULE TEST button: move to the Module test screen;

− Reset button: clear any Locking error relevant to the

module;

− Back button: move to the previous screen.

Fig. 62

Module Screen

9

IMPORTANT: When resetting a Locking error of the Managing

module, the whole boiler will be switched OFF and then

restarted.

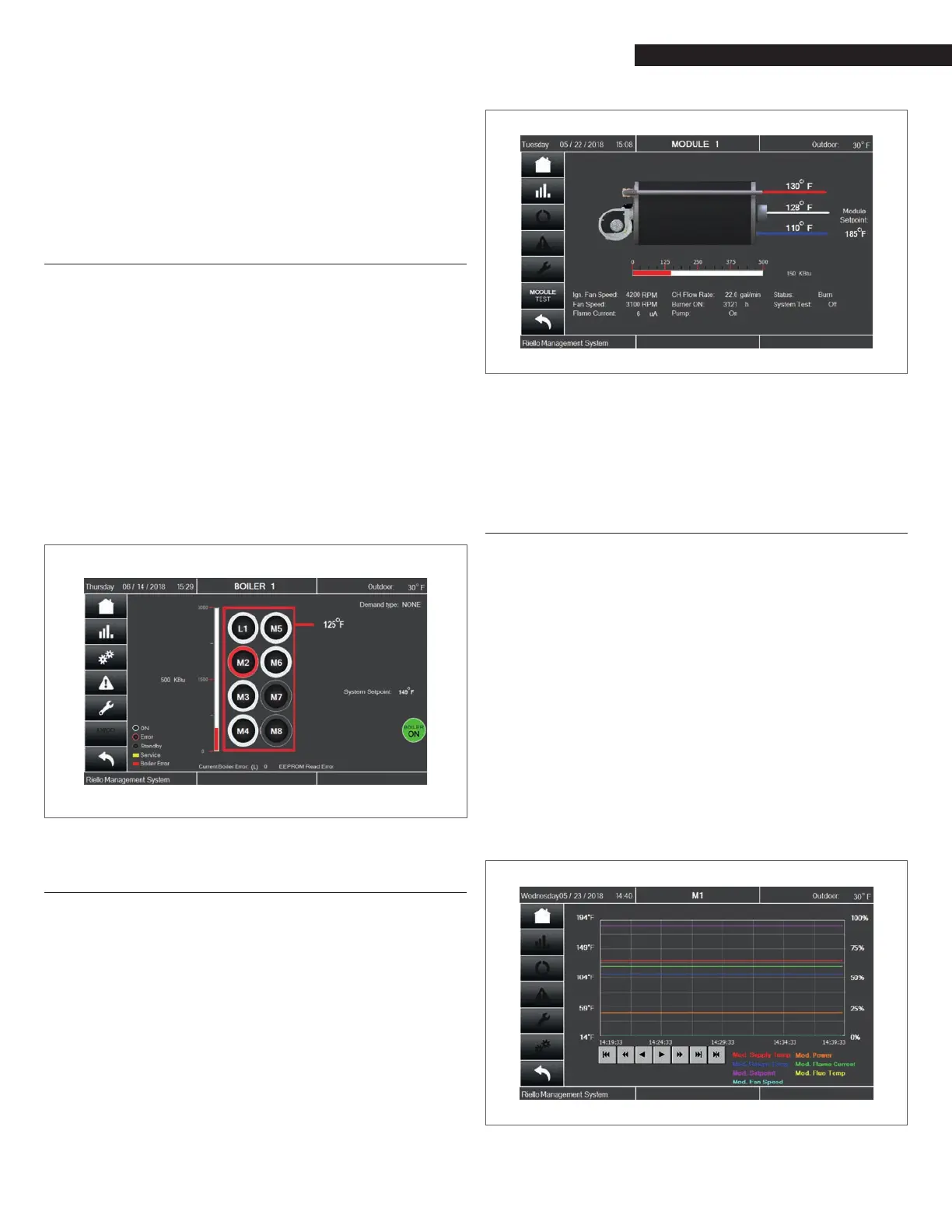

6.3.5 Performance Screen

The Control system is able to show the last 10 minutes “real time”

performance of the plant. In addition, history performance of the

system is available, starting from 60 days prior the current time.

The screen shows different information according to the context.

The Cascade Performance screen includes the trend of:

− Current power input;

− Targeted temperature setpoint;

− Current supply temperature.

The Boiler Performance screen includes the trend of:

− Current power input;

− Targeted temperature setpoint;

− Current supply temperature.

The Module Performance screen includes the trend of:

− Current power input;

− Targeted temperature setpoint;

− Current supply temperature.

Fig. 63

Performance Screen

Loading...

Loading...