60

SHUTDOWN

60

APPENDIX

APPENDIX

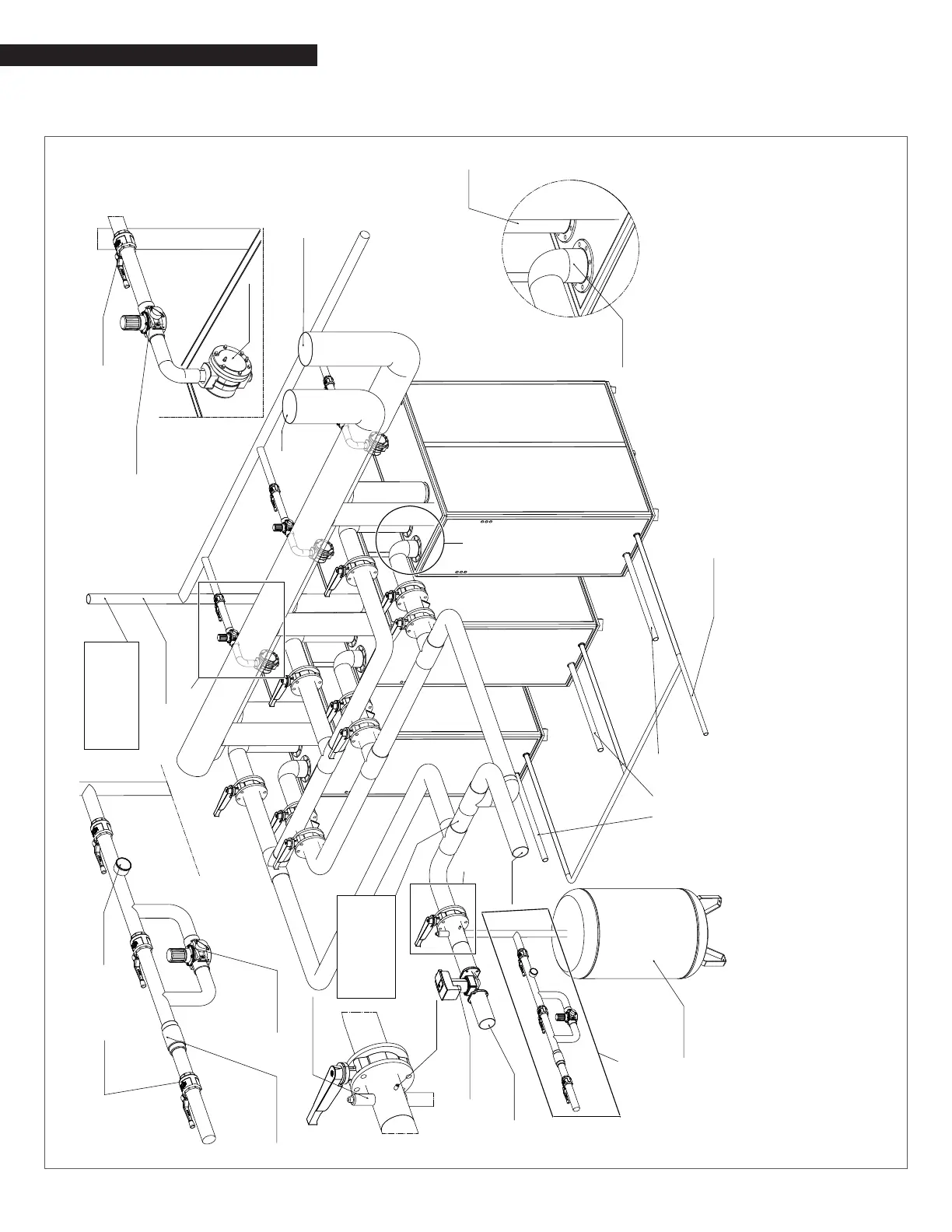

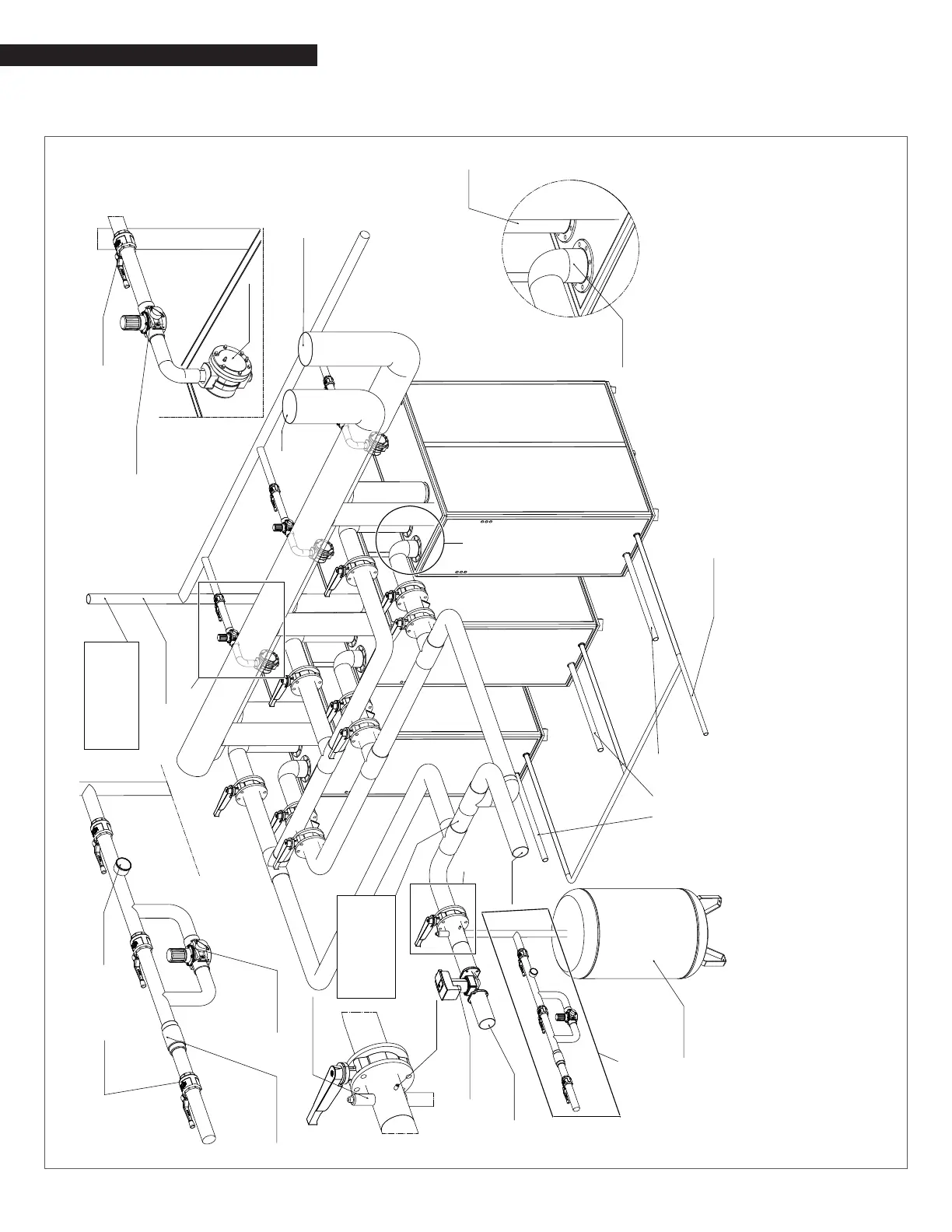

ARRAY AR 1000 / AR 1500 / AR 2000 Multiple Boiler Installation

Detail D

PRESSURE

REGULATOR

MANUAL

SHUTOFF

VALVE

GAS FILTER

(MANDATORY)

Detail A

Detail B

Detail C

EXPANSION

B

TANK

NOTES:

7.MANDATORY: BOILER STRAINER (20 MESH OR FINER).

8. THE CONDENSATE DRAIN TUBE MUST PITCH AWAY FROM THE BOILER (1/4" SLOPE PER FOOT) AND MUST NEVER REDUCE ITS DIAMETER DOWNSTREAM

9. IN CASE OF COMMON VENT PIPE, AN ADDITIONAL SEPARATE CONDENSATE DISCHARGE LINE MUST BE ADDED AT THE FOOT OF THE VERTICAL COMMON STACK.

THIS LINE MUST BE SYPHONED ADEQUATELY, ACCORDING TO THE CALCULATED MAXIMUM FLUE PRESSURE IN THE COMMON VENT PIPE

10. IF THE RETURN PIPING METHOD IS DIFFERENT FROM THE ONE SHOWN, THERE MAY BE SOME MINOR FLOW IMBALANCES.

6. RECOMMENDED: GAS REGULATOR (AND IS REQUIRED WHEN SUPPLY PRESSURE IS GREATER THAN 13.5" WC).

5. PIPING SHOWN IS PRIMARY/SECONDARY.

4. INSTALL A MINIMUM OF 6 DIAMETERS OF OF STRAIGHT PIPE UP AND DOWNSTREAM OF ALL CLOSELY SPACED TEES.

3. INSTALL A MINIMUM OF 12 DIAMETERS OF STRAIGHT PIPE UPSTREAM OF ALL CIRCULATORS.

2. INSTALLATIONS MUST COMPLY WITH ALL LOCAL CODES.

1. THIS DRAWING IS MEANT TO DEMONSTRATE SYSTEM PIPING CONCEPT ONLY.

GAS SUPPLY

COMMON PIPE DIAMETER

MUST BE SIZED FOR LESS

THAN 4.0 ft/sec COMMON

PIPE LENGHT BETWEEN THE

CLOSE TEES MUST BE 3 TO

5 TIMES ITS DIAMETER

C

MAINTAIN A

RECOMMENDED 8"

PRESSURE (MINIMUM

4") AT MAXIMUM

BTU/HR INPUT

AIR ELIMINATOR

SUPPLY

SENSOR

(MANDATORY)

SYSTEM

CIRCULATOR

SECONDARY

SYSTEM

SUPPLY

SECONDARY

SYSTEM

RETURN

MAKE-UP

WATER

BACKFLOW

PREVENTER

PRESSURE

REDUCING

VALVE

PRESSURE

GAUGE

RELIEF VALVES

DRAIN PIPE

CONDENSATE

DRAIN PIPE

SUPPLY

RETURN

FLUE

COMBUSTION AIR

A

D

Loading...

Loading...