97

Alarm codes

EN

6.1 ALARM MENU

The

Pro-Dialog+

panel features many troubleshooting

functions. In case of error, an alarm will be triggered and

its identicationcodewill beloggedintothealarm menu,

CUR_ALRMandALARMRSTsub-menus.

ThecontrolpanelLEDswillsignalthealarms.Itisreminded

that:

• ashing LED indicates that at least one circuit of the

machine

isinoperationbutthereisawarningsituation.

• steadyLEDindicatesthatatleastonecircuitofthemachi-

ne

hasstoppedduetoanerror.

ALARMRST sub-menu shows up to ve alarm codes active

withintheunit.

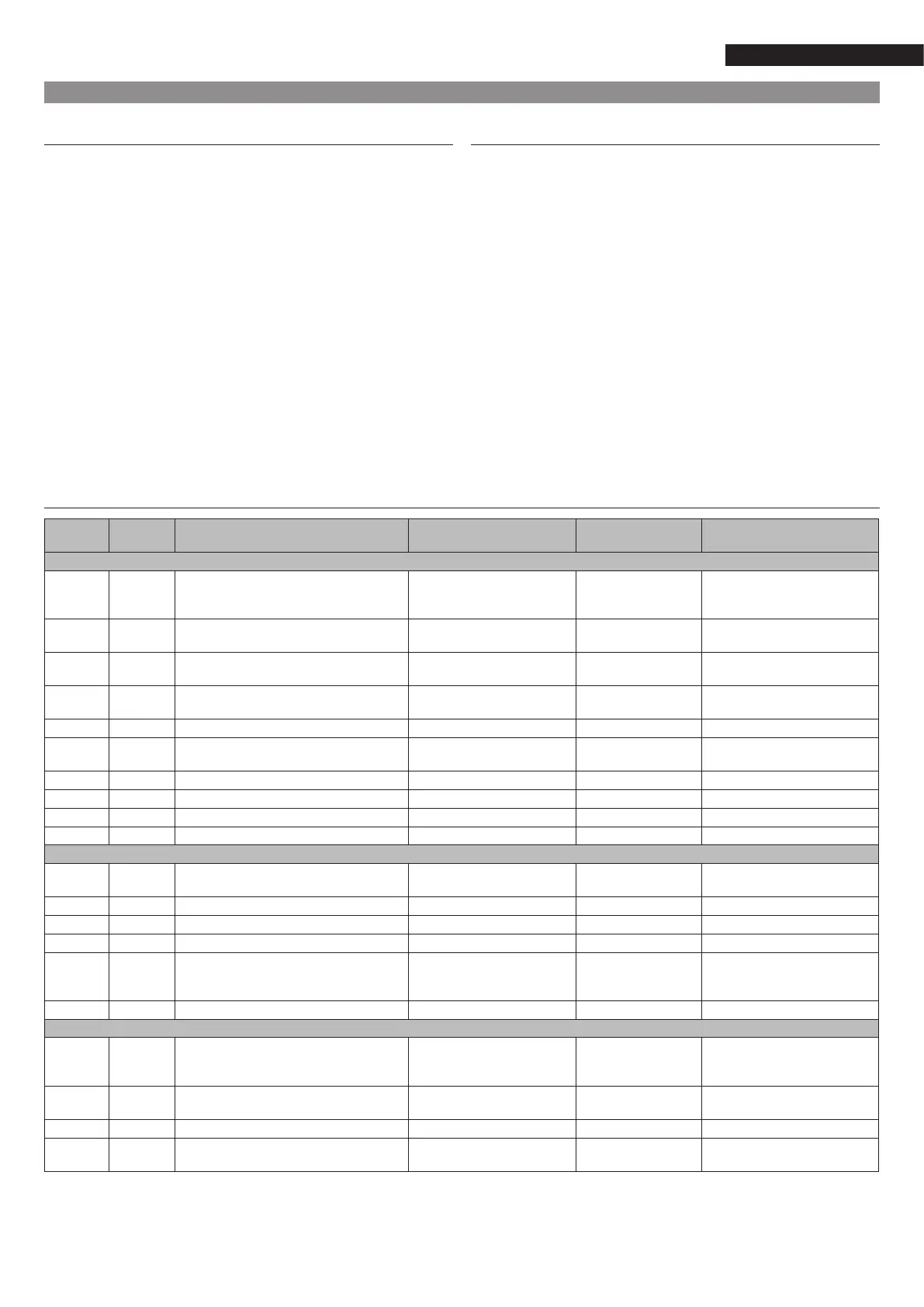

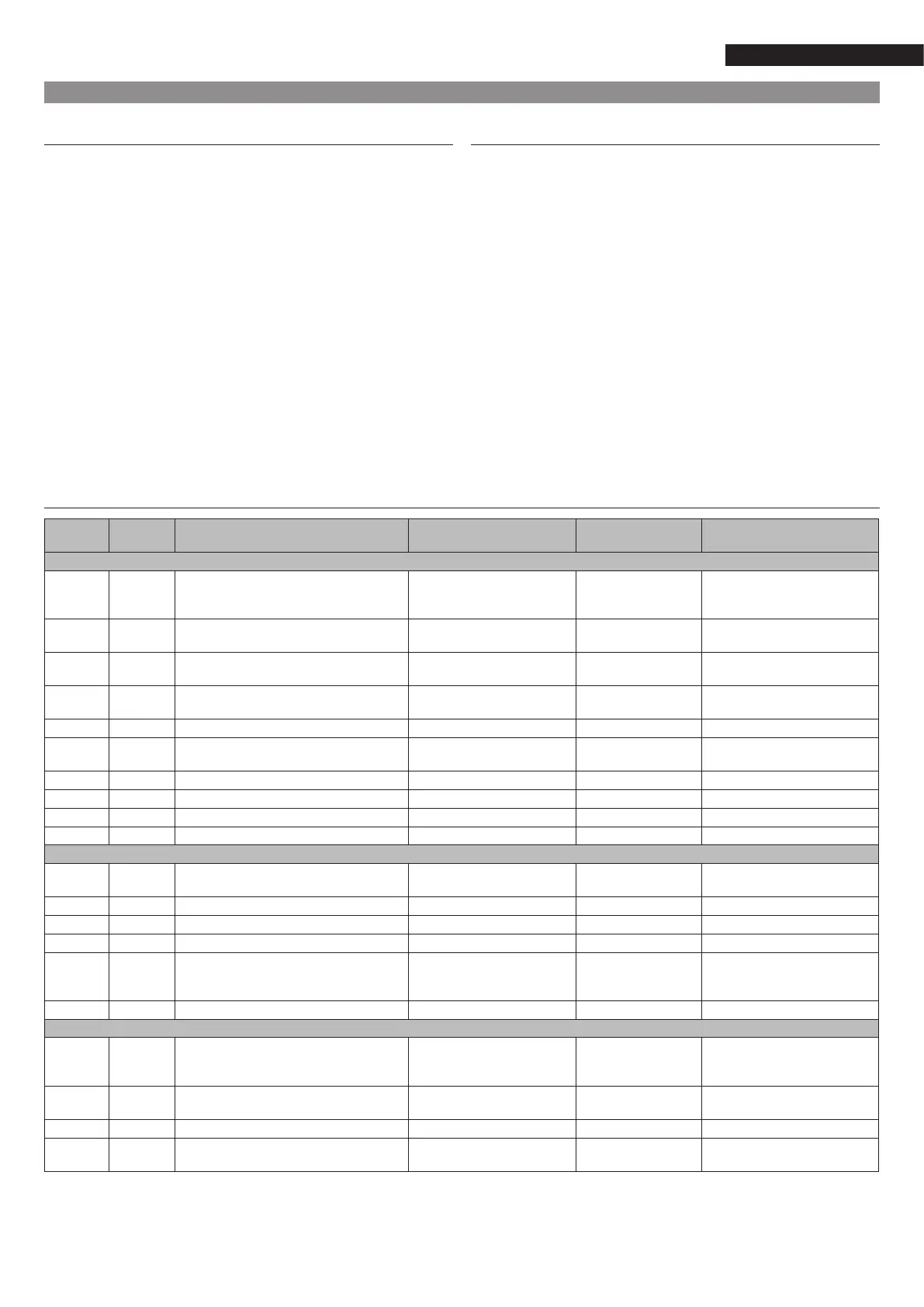

6.3 ALARM CODES

Alarm

number

Alarm code Alarm description Reset mode Probable cause Control system reaction

Thermistor faults

1 th-01 Heatexchangerenteringwatertemperature

sensor fault

Automatic,whenthe

temperaturedetectedisback

to normal again

Thermistor fault Unit stop

2 th-02 Heatexchangerleavingwatertemperature

sensor fault

As above As above As above

3 th-03 Defrost fault of cooling circuit A As above As above Stopofthecircuitifthedeviceis

inheatingmode

4 th-04 DefrostfaultofcircuitBorsecondfaultof

circuit B sensor

As above As above As above

5 th-10 Outdoortemperaturesensorfault As above As above Unit stop

6 th-11 CHWS sensor fault

(Master/Slave)

As above As above Stop of the Master/Slave operation

mode

7 th-12 Circuit A suction sensor fault As above As above Stop of the circuit

8 th-13 Circuit B suction sensor fault As above As above As above

9 th-44 Faultofsuctionsensor,heatexchanger1 As above As above As above

10 th-45 Faultofsuctionsensor,heatexchanger2 As above As above As above

Pressure transducer faults

11 Pr-01 DeliverypressuretransducerAfault Automatic,whenvoltageis

backtonormal

Transducerfaultor

installation error

Stop of the circuit

12 Pr-02 DeliverypressuretransducerBfault As above As above As above

13 Pr-04 CircuitAsuctionpressuretransducerfault As above As above As above

14 Pr-05 CircuitBsuctionpressuretransducerfault As above As above As above

51 Pr-24 Pressuresensorfaultatwaterinlet Automatic,whenthevalueof

thevoltagetransmittedbythe

sensorisbacktonormal

Sensor fault or

installation error

Stop of the circuit

52 Pr-25 Pressuresensorfaultatwateroutlet As above As above As above

Communication with slave boards

15 CO-BB CommunicationlosswithNRCP2board Automatic,when

communications have been

restored

Communication bus

installation error or

slaveboardfault

Compressor A3 or circuit B stop,

accordingtoconguration

16 Co-ht Communicationlosswiththeboardfor

additionalheatingsteps

As above As above Stopofadditionalheatingsteps

17 Co-e1 CommunicationlosswithEXVvalveboard As above As above Unit stop

18 Co-o1 CommunicationlosswithPD-AUX1board As above As above Device stop if equipped with

optionalwaterpressuresensor

6.2 ALARM RESET

Once the error is solved, the alarm code

must be reset. Reset procedure can

bemanualorautomatic,dependingonthetypeofcodeof

alarm. Alarm reset can be carried out al-

so

with machine running. In case of power blackout

the

unitwillautomaticallyrestartwithouttheenablingre-

questfromthecontrolpanel.

Nevertheless,ifthemachine,duringthisinterruption,regi-

sters

somealarms,theycaninhibittheautomaticrestart.

The manual resetprocedure of the alarms must be carried

outfromtheALARMRSTmenu,RST_ALMparameter.However,

accesstothisparametercanbeprotectedbyapassword(that

canbeconguredfromtheGENCONFmenu).

Loading...

Loading...