33

20140894

Start-up, calibration and operation of the burner

7.4 Combustion characteristics

The burner delivery in the 2nd stage must not exceed the rated

delivery for the boiler, and should be adjusted in relation to the

user's effective heating requirements and selected within the

MAX firing rates (See page 10). A lower setting of the boiler pro-

vides for a lower flue gas fume temperature, thus increasing com-

bustion efficiency and saving fuel.

The burner's delivery in the 1st stage is usually 50% of the de-

livery in the 2nd stage and must be contained in the MIN. values

range listed above the firing rates on page 10. The burner's 1st

stage delivery can even be lower than 50% of the 2nd stage de-

livery whenever it does not cause the formation of too much con-

densate in the stack. It may also be higher than 50% when

required by the reasons listed on page 17 in the "Choice of noz-

zles for 1st and 2nd stage" paragraph.

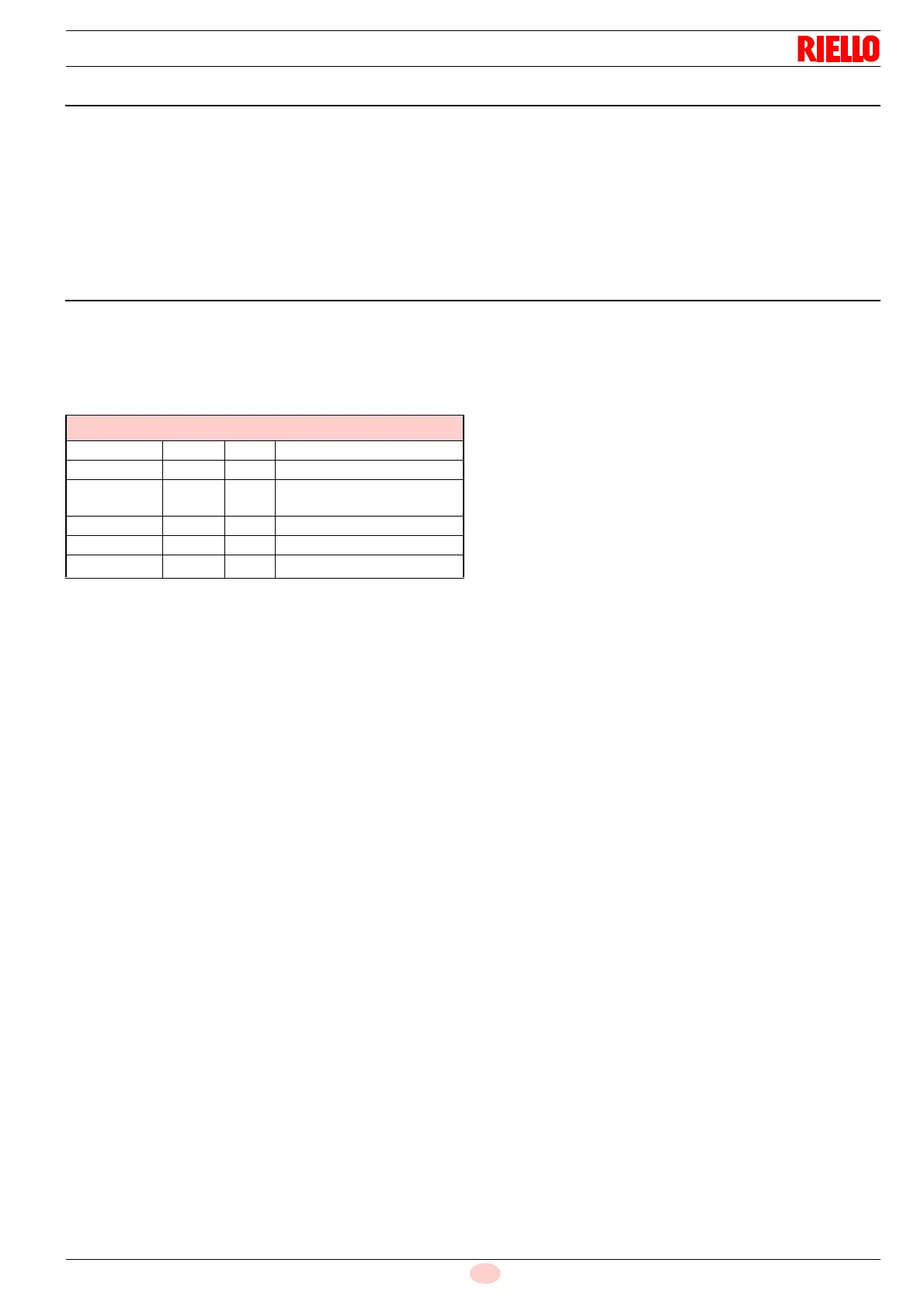

7.5 Emissions into the atmosphere

Test boilers UNI-DIN (Fig. 6 on page 12): emissions of Bacha-

rach-CO

2

-CO-CxHy-NOx obtained in laboratory tests with our

burners proved to be lower than the limits defined by EC Norms

EN 267 under the operating conditions established by these

standards, see (Tab. M).

Tab. M

Commercial boilers: emissions of Bacharach-CO

2

-CO-CxHy-

NOx must not exceed the limits imposed by locally-applicable

regulations for burner installations. In particular, the CO

2

level

should not be higher than 13.5% in order to prevent variations in

the draught and air temperature or dirty burner conditions from

causing polluting combustion.

An insufficient CO

2

level must also be avoided, since, in addition

to raising costs and falling short of the established range, this can

also be the cause for the generation of a dangerous quantity of

uncombusted hydrocarbons in the flue gas (yellow Bacharach)

and the detachment of the flame upon ignition.

The combustion values measured may be considered reliable

only if there are no entries of air between the burner and the stack

flue gas sampling point. Check for penetration of outside air by

placing a column of smoke near the suspected leak in the seal: if

the smoke column is drawn towards the seal there must be an en-

try of air.

EN 267 (5-91)

Stage 1° 2°

Bacharach n° < 2 < 1

CO

2

% > 11.3 > 12.3÷12.7 (15÷100 kg/h)

> 12.7 (> 100 kg/h)

CO ppm < 100 < 100

CxHy ppm < 10 < 10

NOx (3% O

2

)

mg/Nm

3

< 150 < 150

N.B. Excess air % = CO

2

max : CO

2

measured

CO

2

max = 15,2%

Example CO

2

measured = 13,5%

Excess air = 15,2 : 13,5 = 1,13 = 13%

Loading...

Loading...