20140894

38

Maintenance

Nozzles

Do not clean the nozzle opening; do not even open it. The nozzle

filter however may be cleaned or replaced as required. Replace

the nozzle every 2-3 years or whenever necessary. After chang-

ing the nozzle, the combustion must be checked.

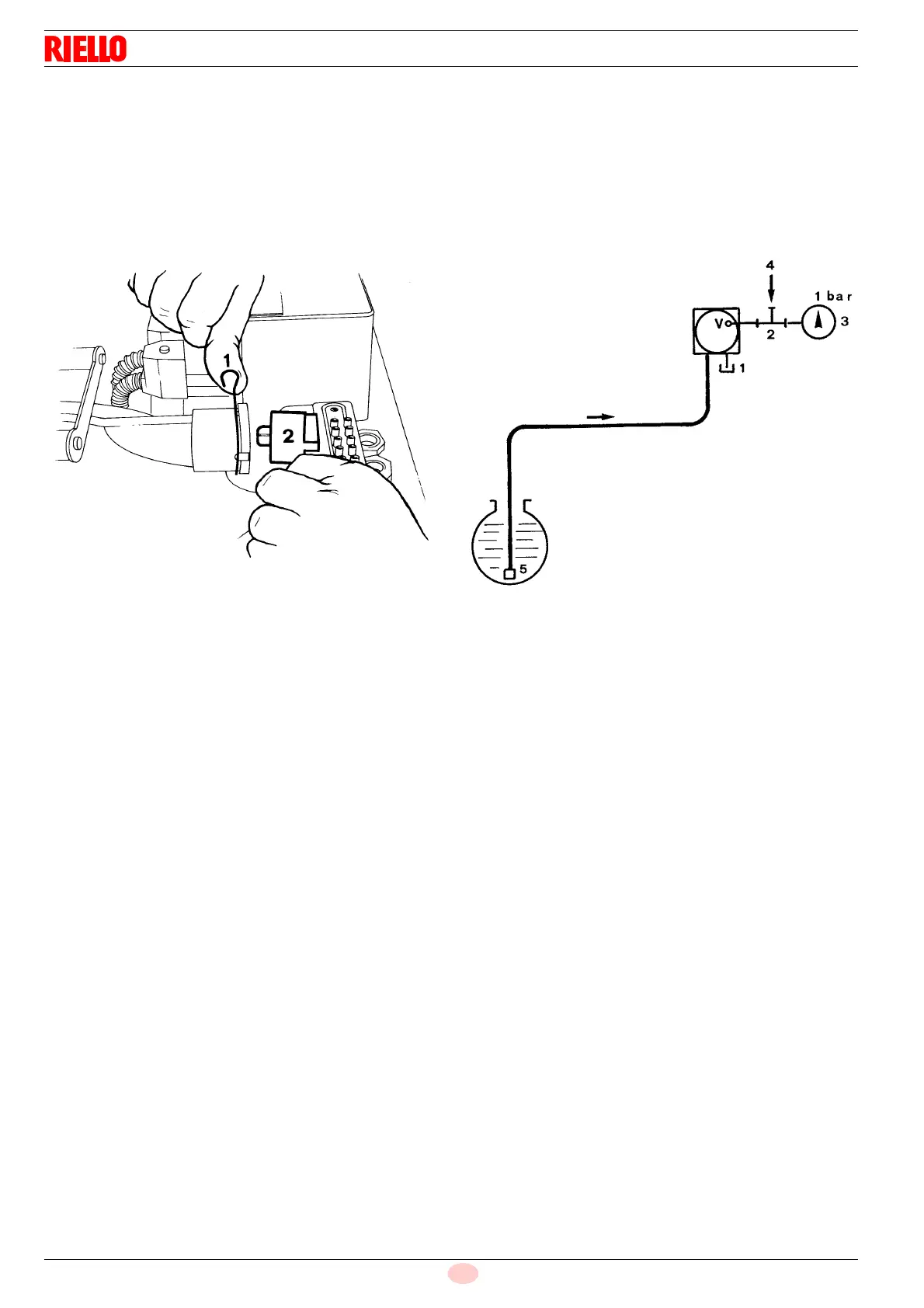

Sensor flame (Fig. 39)

Clean the glass cover from any dust that may have accumulated.

In order to extract the sensor 2) from its seat, raise the spring 1).

Hoses

Check to make sure that the flexible hoses are still in good con-

dition and that they are not crushed or otherwise deformed.

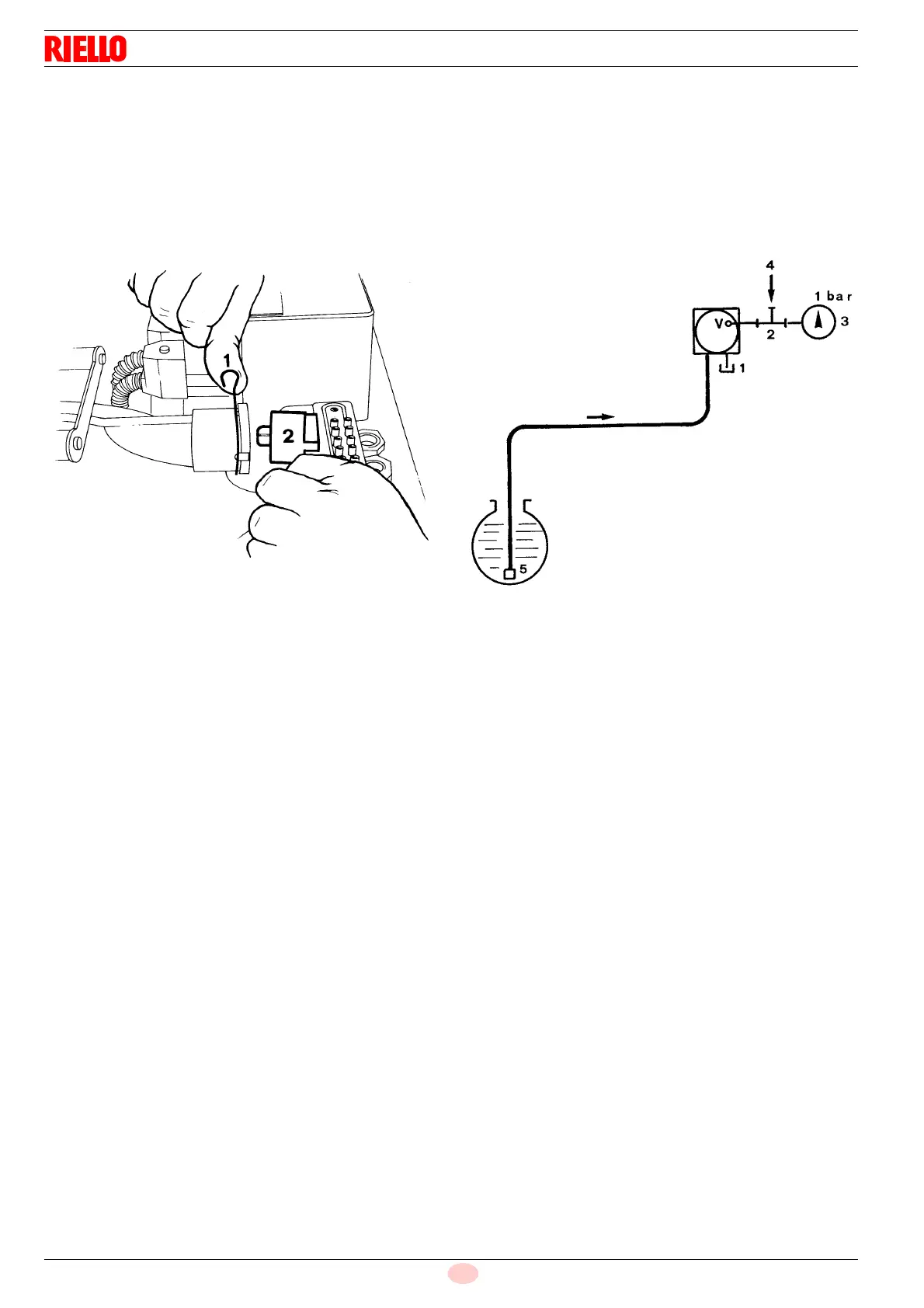

Gas oil fuel supply line (Fig. 40)

If the previous checks have suggested that air may be entering

the circuit somewhere, pressurize the circuit piping. Plug the

pump's return line connector 1) (Fig. 40) after removing the flexi-

ble hose. Install a union T 2) (Fig. 40) on the vacuum meter at-

tachment. On one branch of the T install the pressure gauge 3)

and on the other branch 4) inject air at a pressure of 1 bar. After

the injection of air has stopped, the gauge reading should remain

stable. The suction piping must be equipped with a foot valve 5).

Fuel tank

Approximately every 5 years, or whenever necessary, suck any

water or other impurities present on the bottom of the tank using

a separate pump.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially the flue gas temperature and combustion cham-

ber pressure. Lastly, check the condition of the flue gas stack.

Close the burner and apply power.

If the combustion characteristics measured at the beginning of

the control operation do not match the values listed in the previ-

ous inspection's technical report sheet or fail to provide satisfac-

tory combustion, the burner must be re-calibrated.Write the new

values down on the data sheet illustrated on page 41 or a similar

document. These values will be useful for comparison during fu-

ture checks. Lastly, check to make sure that the fan air gate valve

is in good condition and that the screws are tightly locked. The

tightness of the screws that fasten the cables to the burner termi-

nal block must also be checked. Clean the outside surfaces of the

burner and spray all parts that show signs of rusting with silicon

rust-preventer.

Loading...

Loading...