M3

CONDENSING WATER BOILER

21

34-1115 12/15

8.2 Vent Installation – General

The M3 boiler can be vented either vertically, through a ceiling or roof, or horizontally through a wall. The M3 boiler is

a Category IV positive pressure gas appliance, so venting and can be routed to the outdoors in any direction from

the vent connection of the boiler, except down. Unless the list vent system manufacturer states otherwise, the vent

must be installed and supported at least every four feet to slope downward toward the boiler vent connection with at

least ¼ inch drop per linear foot of horizontal vent run, to allow proper drainage of accumulated condensation. All

penetrations through walls and roofs must be weather and gas tight, such that rain and products of combustion

cannot pass from outdoors back indoors.

WARNING: Do not connect this appliance to an existing or traditional gas vent or chimney, do not use a

barometric damper in the vent and do not combine the vent with any other appliance, except as provided in

the section titled “Combining Category IV Vents.” Such venting could result in failure of the venting system

and/or exposure to carbon monoxide which can result in property damage, personal injury or death.

8.2.1 Maximum Vent Length (Equivalent Length)

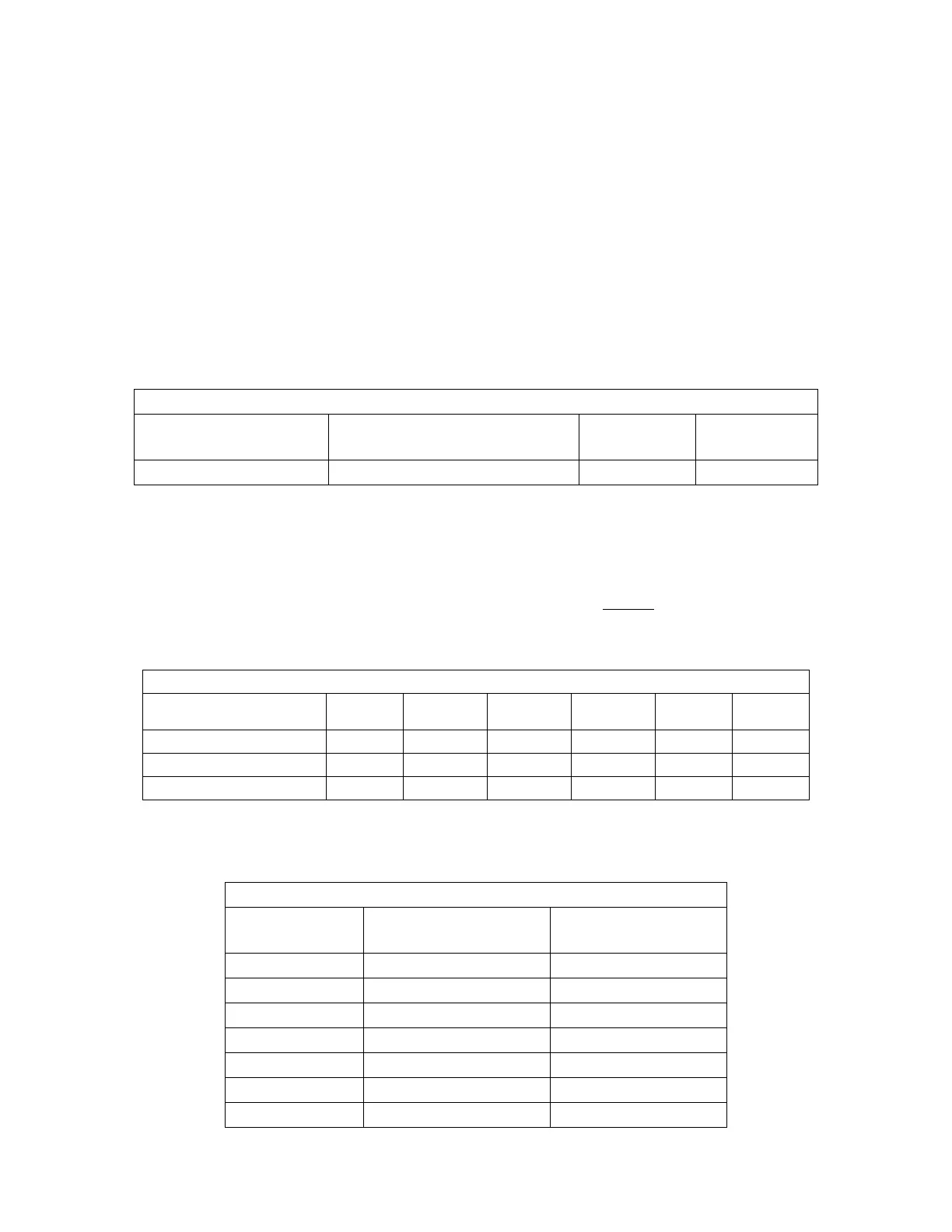

The maximum length of field supplied Category IV vent is shown in the chart below:

Maximum Vent Length in Equivalent Feet

Vent Size

4"

(Use only on Models 400, 500 )

6" Vent

(All Models)

8" Vent

(All Models)

Max Equivalent Length 100 eq. feet 150 eq. feet 200 eq. feet

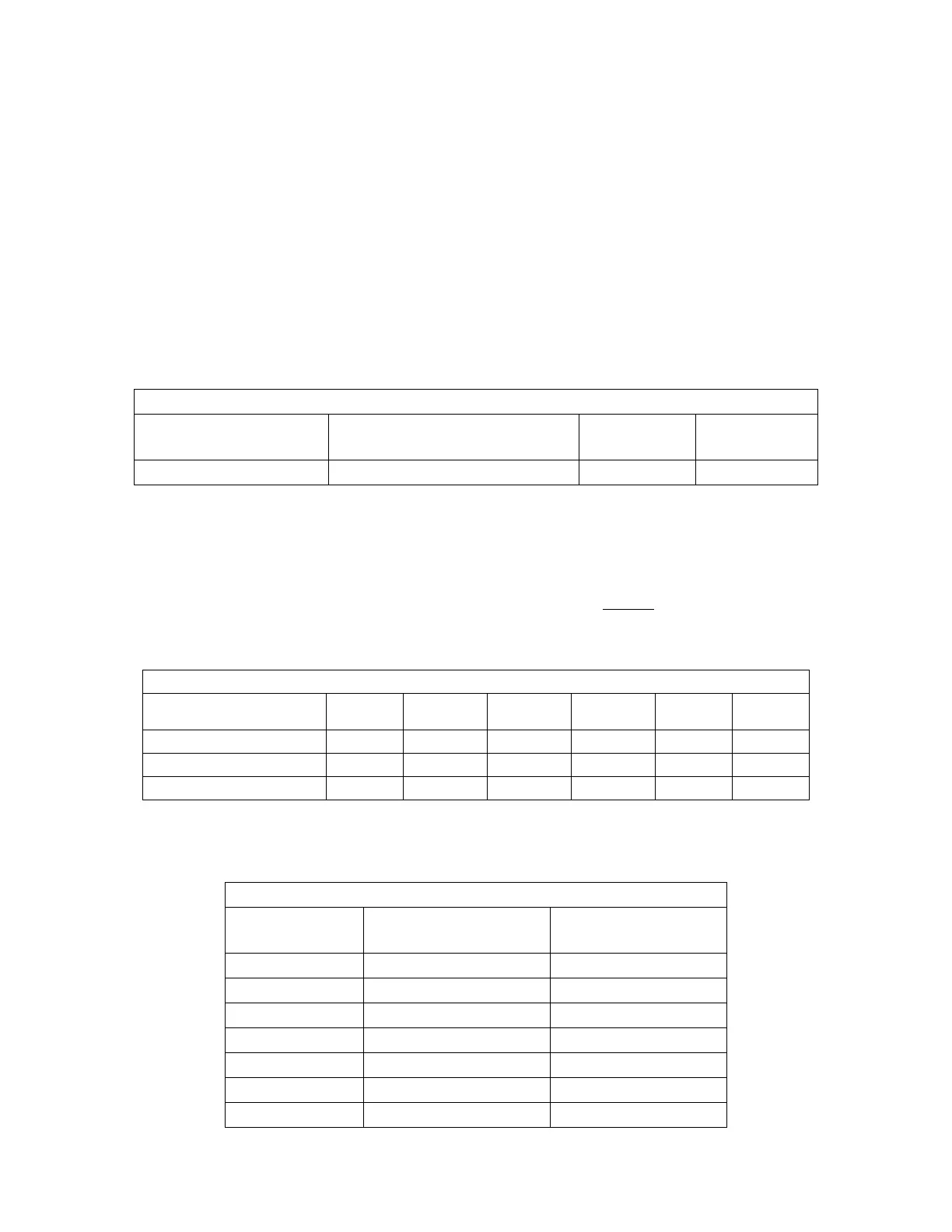

Vent pipe fittings reduce the maximum allowable vent length. For listed Polypropylene or Stainless Steel Category IV

venting systems use the vent manufacturer’s equivalent length deduction for all elbows, terminations, etc. For PVC

and CPVC vents, or if the information is not readily available from the vent manufacturer, use the Vent Pipe Fitting

Equivalent Length chart below to find the total equivalent length for all vent fittings in your combustion air system.

Then subtract this number of feet from the total equivalent length allowed in Maximum Vent Length in Equivalent

Feet chart above. The sum of this calculation is the maximum length of straight vent allowed. If a longer length is

required, repeat the calculation using a larger vent size. When using this chart, no additional deduction is required for

the addition of the vent system terminal.

Vent Pipe Fitting Equivalent Length

Vent Pipe:

PP *

4" Vent

Other **

4” Vent

PP *

6" Vent

Other **

6” Vent

PP *

8" Vent

Other **

8” Vent

90º Elbow 22 feet 22 feet 22 feet 16 feet 18 feet 11 feet

90º Long Radius Elbow 12 feet 12 feet 14 feet 10 feet 8 feet 6 feet

45º Elbow 12 feet 12 feet 14 feet 10 feet 8 feet 6 feet

* PP = polypropylene ** Other = PVC, CPVC or Stainless Steel

The following vent information is provided for use in design calculations, if needed.

Venting Specifications

Input MBtu/h

Combustion Air

Volume (cfm)

Max Vent

Press. ” W.C.

399 135 0.5

500 170 0.5

600 205 0.5

650 221 0.5

700 239 0.5

750 255 0.5

800 273 0.5

Loading...

Loading...