M3

CONDENSING WATER BOILER

38

34-1115 12/15

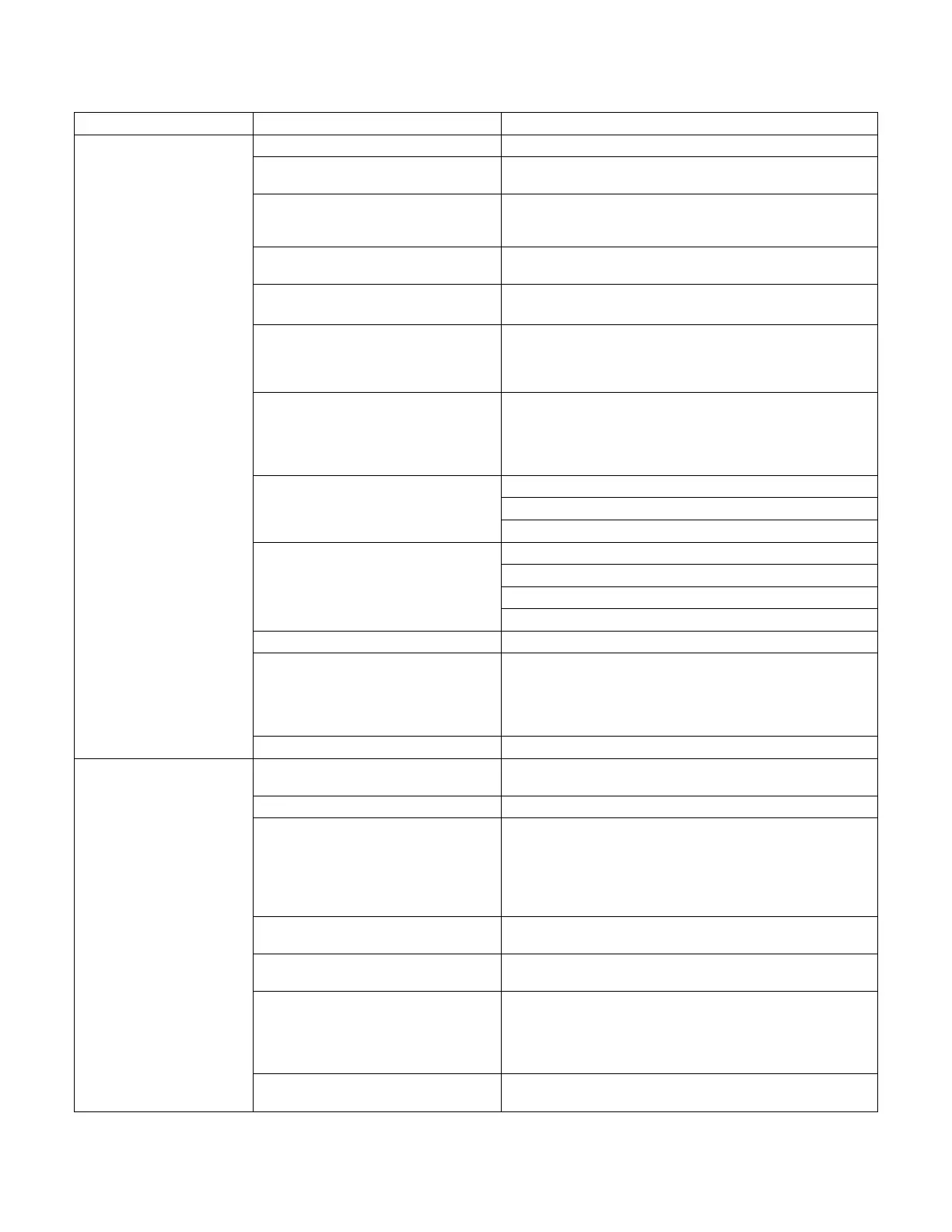

14 TROUBLESHOOTING GUIDE

Problem Probable Cause Corrective Action

Starting or Pre-purge

Failure

Power Supply Check fuse and/or circuit breaker.

On-Off Switch

Check if On-Off switch is illuminated when on. If not check

panel fuse or incoming power.

Temperature Control

TempTrac

Check that the operating temperature control is set higher

than the temperature of the boiler. See Table 10.8 for

indications of control or sensor faults.

Remote enable/disable open

See Table 10.8 for indication of condition. Enable boiler or

place jumper between terminals R1-R2.

Electronic Low Water Cut-off

(when installed)

Check internal ELWCO board for indication of failure. The

red LED indicates a safe condition. Manual reset is required.

Gas Pressure Switches

(when installed)

Gas pressure switches are attached to the gas train. Check

for a tripped condition indicated by the manual reset button

on the switch. Correct low gas pressure condition at the

supply.

High Temperature Limiting Device

One manual, one auto reset limit device, set at 210F and

200F respectively, located at the control well on the top head

of the tank. A high temperature condition may be caused by

a failure of the TempTrac, temperature sensors. The failure

can require manual reset depending which limit is tripped.

Combustion Air blower

Check if fan control relay is closed

Blower motor may have failed.

Fan VFD may be defective. Verify proper voltage.

Air-proving Switch

(if blower is functioning)

Check switch contacts are closed.

Check for 120V at the N.O. side of air switch

Check for 120V at the common side of air switch

Check if switch tubing is connected on both ends

Flame Safeguard Control Check for bad ground or bad control. Replace if necessary.

Remote Proving Interlock

When terminal C1 and C2 are used a proving circuit for

remote equipment, failure to close this circuit within the

allotted time for Call-for-Heat will prevent operation and

cause an alarm indication. Check for proper operation and

proving of remote equipment.

Loose Wire Connections Check connections to all components

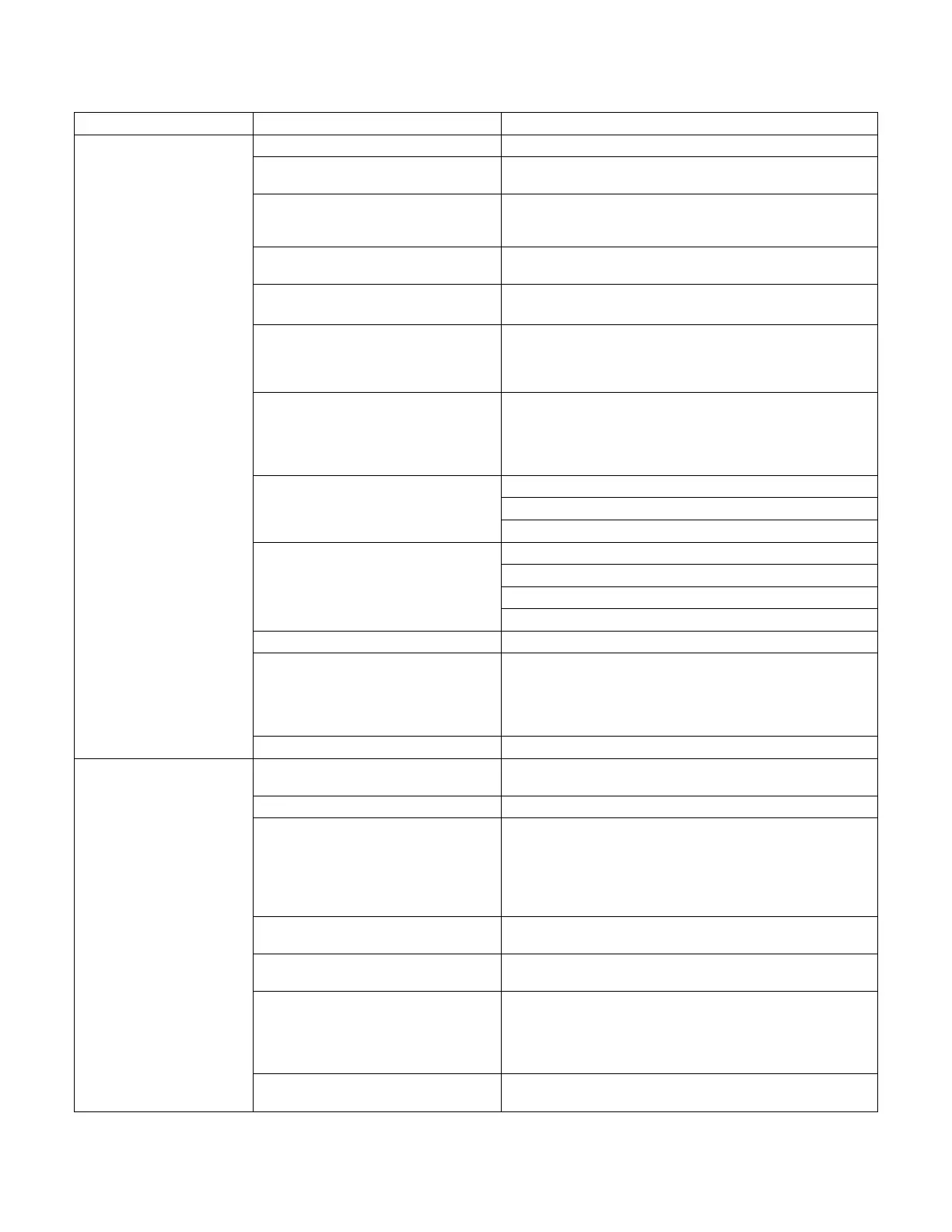

Flame Failure

Power Supply

120 VAC is required for operation. Low voltage can cause

failure. Voltage below 110 VAC must be investigated.

Flame Safeguard Control Check for bad ground or bad control. Replace if necessary.

Hot Surface Igniter

Check resistance at room temperature and then the

amperage draw during heat-up. Replace if the measured

amperage is not within 3.5 to 5.0 Amps or if measured

resistance is not within 40-100 ohms (at room temperature).

Also, check for overheating condition due to damaged

refractory around igniter.

Air-proving Switch

Check if switch is bouncing. Adjust or replace. Check VFD for

proper speed settings.

Gas Pressure

Check for proper inlet static and dynamic gas pressure, 3.5”

WC minimum.

Combustion

Inadequate flame signal may result from improper

combustion. Adjust to proper CO2 levels at low fire. Inability

to achieve proper CO2 throughout the modulation range may

be caused by a defective gas valve, a defective regulator or

blockage in the in the burner or combustion air supply.

Grounding

Check for proper ground from the flame control to the burner

housing.

Loading...

Loading...