First start-up

Installation, use and maintenance manual – Next-R

45

5

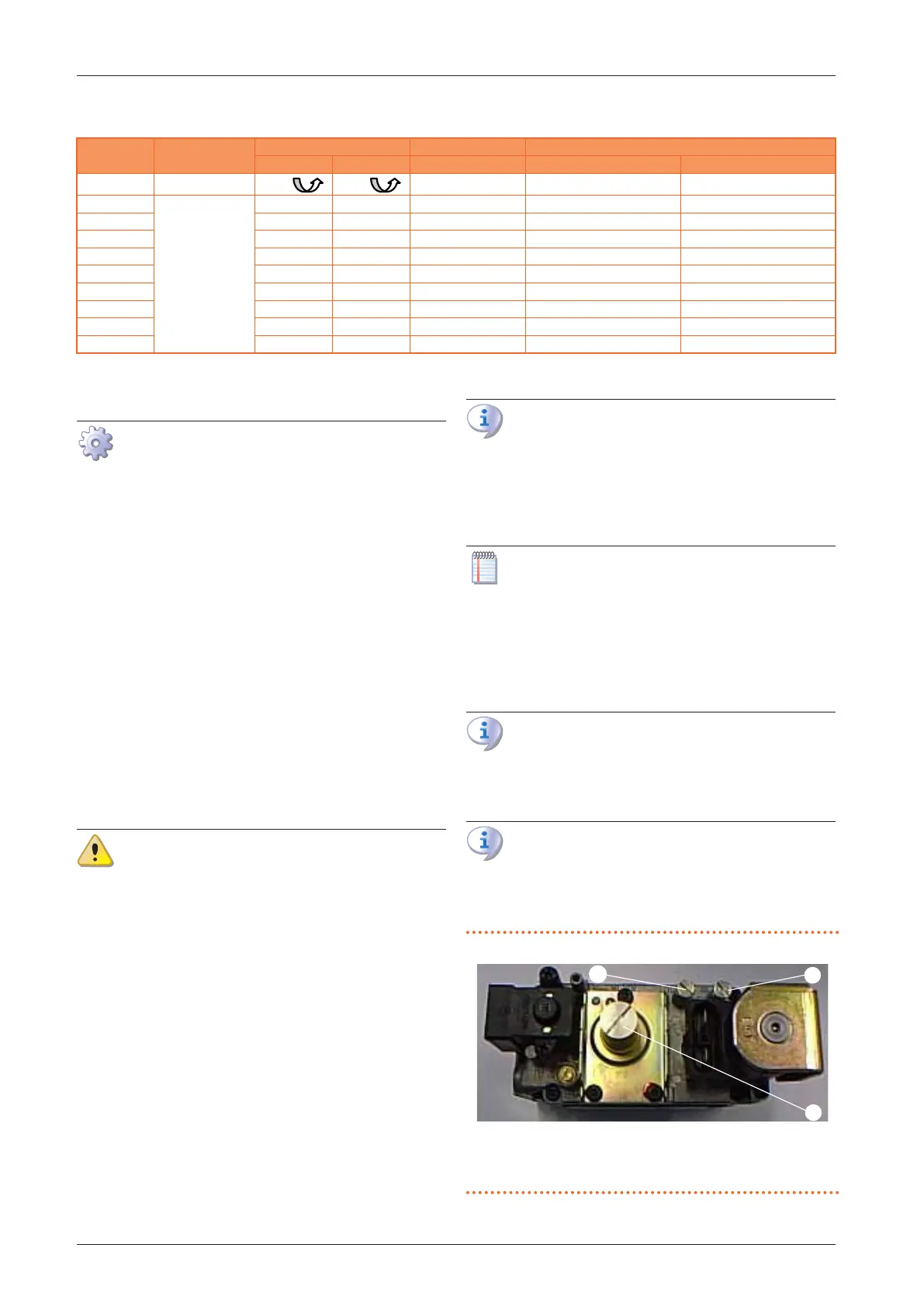

Table5.5 R50 gas valve setting table

Gas

Gas network

pressure

Screw pre-adjustment Oset pressure CO

2

percentage in fumes

Throttle Oset nominal Minimal heat input Nominal heat input

Type mbar

turns turns

Pa % %

G20

See Table

3.1

p.29

-14 -3 ¾ -10 8,6 9,2

G25 full open -3 ¾ -10 8,5 9,0

G25.1 -16 ¾ -3 ¾ -10 10,0 10,5

G25.3 full open -3 ¾ -10 8,6 9,2

G27 -16 -3 ¾ -10 8,6 9,0

G2.350 full open -3 ¾ -10 8,6 9,1

G30 -4 ½ -3 ¾ -10 9,9 10,5

G31 full open -3 ¾ -10 9,5 10,0

LPG -14 ¼ -3 ¾ -10 9,7 10,3

A tolerance of ±0,3% is applied to all values of CO

2

percentage in fumes.

5.2.2 R60/R80

Figure 5.2

p.45

1. If the appliance is running, switch it o with the appli-

cable control system.

2. Connect a pressure gauge to oset pressure tting (A),

after having rst removed or loosed the sealing screw.

3. Open contact 27 (L-C terminals), or act on the power

level control device to force gas unit heater operation

at minimum power.

4. Switch on the gas unit heater using the provided con-

trol device.

5. After about 2 minutes, the combustion control at min-

imum power can be carried out.

6. Turn the oset adjustment screw until the nominal

oset pressure value shown in the following Tables is

obtained, with a tolerance of ±1 Pa.

7. Ensure the CO

2

value is between values indicated in

column "Minimal heat input" of the following Tables,

depending on the model and the gas type used.

Otherwise set CO

2

percentage reading by acting on

the oset adjustment screw.

Check the burner, which must not have reddened

areas.

8. Disconnect the pressure gauge and tighten the seal-

ing screw of the pressure intake (A).

9. Close contact 27 (L-C terminals), or act on the power

level control device to force gas unit heater operation

at maximum power.

10. After about 2 minutes, the combustion control at max-

imum power can be carried out.

11. Ensure the CO

2

value is between values indicated in

column "Nominal heat input" of the following Tables,

depending on the model and the gas type used.

If the check is successful:

12. Set contact 27 (L-C terminals) back in its original posi-

tion or stop manual forcing of the power level.

If the check is not successful:

13. Repeat steps 3 to 7 (excluding step 6) to reactivate the

minimum power operation; check again and, if neces-

sary, correct the CO

2

value in such conditions by actu-

ating the oset adjustment screw.

14. Repeat step 12 to complete the procedure.

Check that the static and dynamic supply gas

pressure values, with the gas unit heater running

at maximum power, correspond to what is shown

in Table 3.1

p. 29

(with low supply gas pressure

values the CO

2

value will also be at minimum

values).

If the control systems are designed so that the

gas unit heater activation request depends on the

room temperature, the gas unit heater may not

start because the room temperature is already at

requested setpoint. In this case, set the forcing for

manual activation on the control system, or close

contact Z9 (Z91-Z92 terminals) manually.

Remember to set contact 27 (L-C terminals) back

in its original position or stop manual forcing of

the power level after the conclusion of checking

operations.

If it has been set, remember to disable the

forcing for manual activation on the control

system, or manual close of contact Z9 (Z91-Z92

terminals).

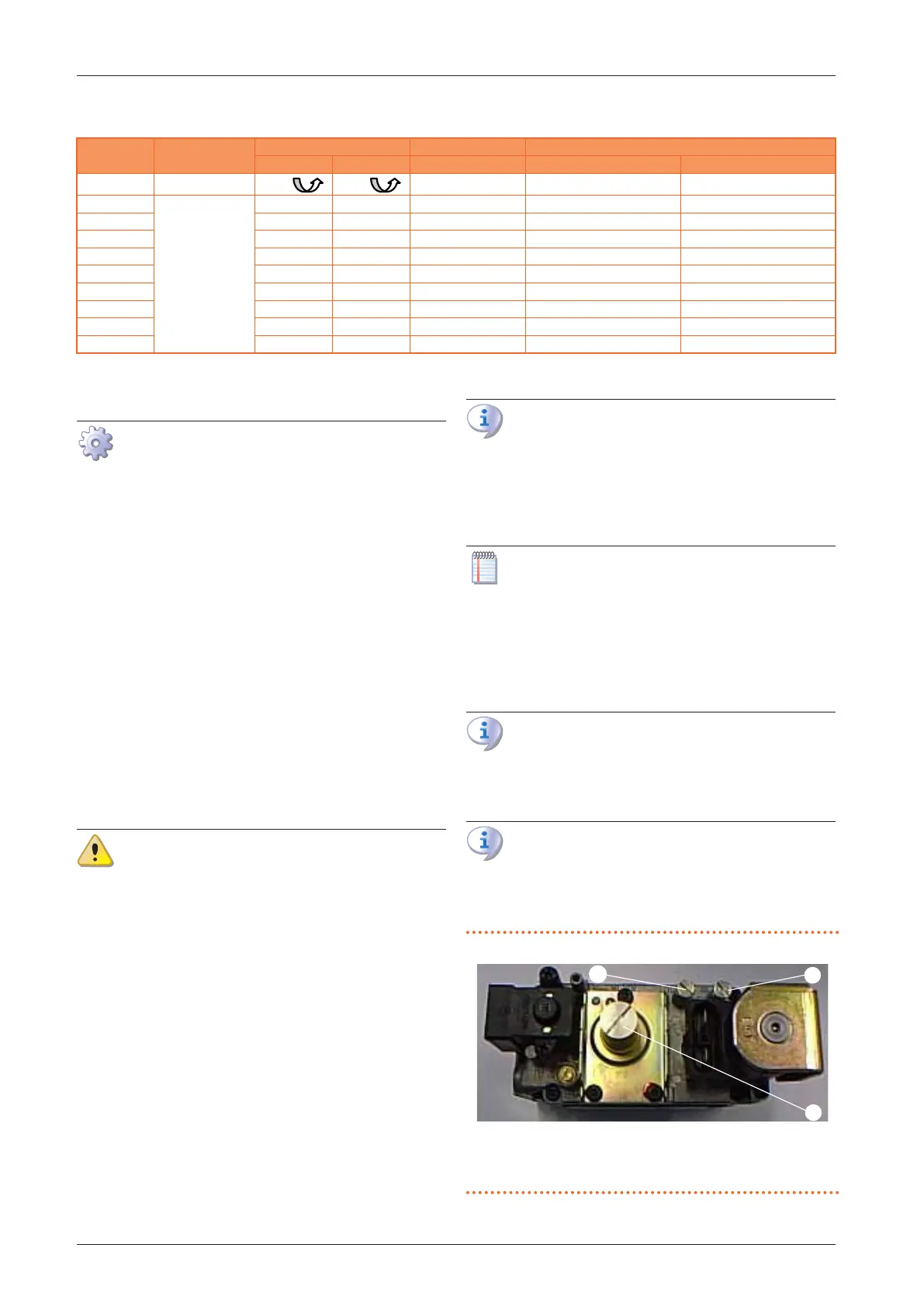

Figure5.2 Gas valve

A Oset pressure intake

B Gas mains pressure intake

C Oset adjustment screw

C

B

Loading...

Loading...