Normal operation

46

6

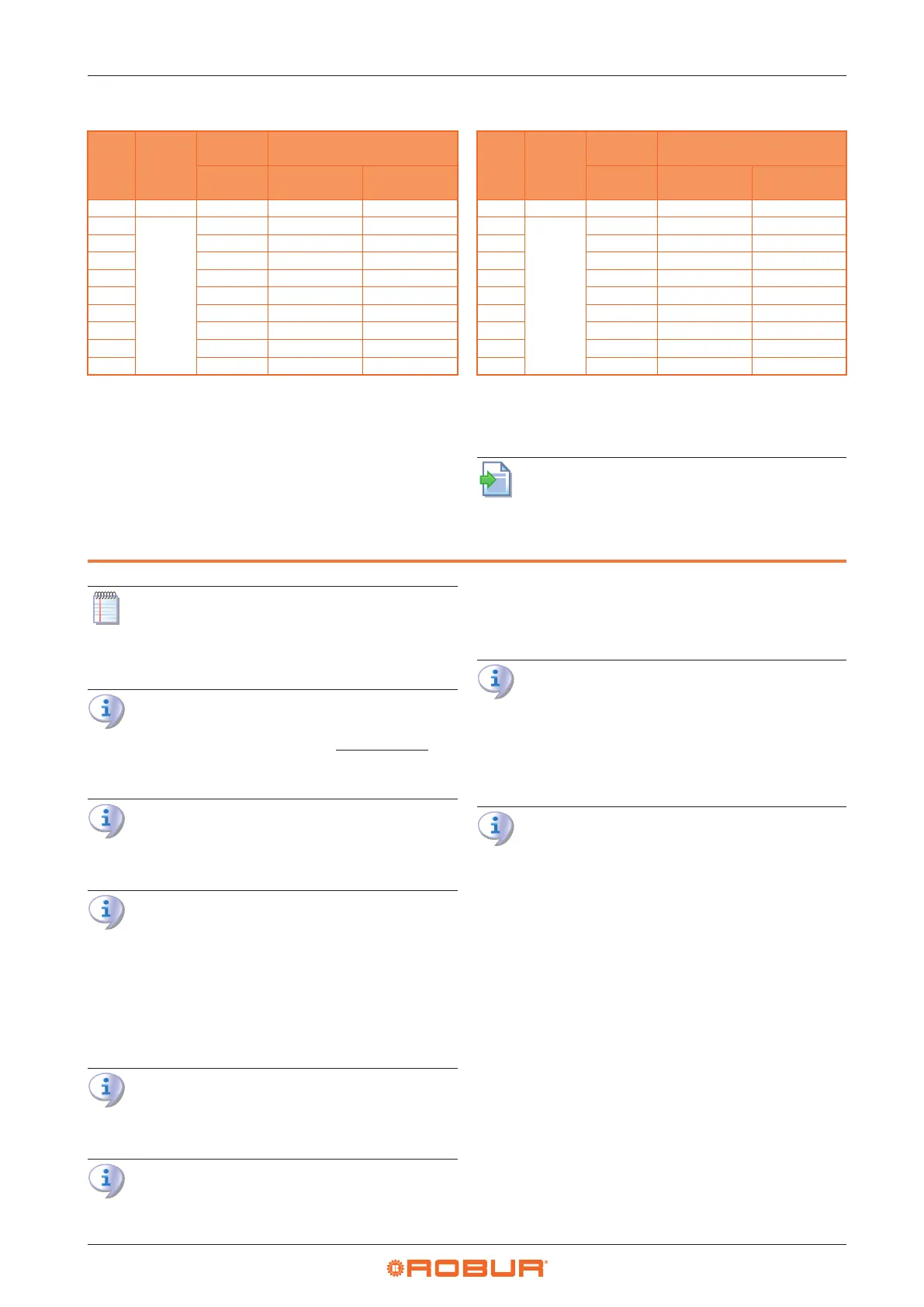

Table5.6 R60 gas valve setting table

Gas

Gas

network

pressure

Oset

pressure

CO

2

percentage in fumes

nominal

Minimal heat

input

Nominal heat

input

Type mbar Pa % %

G20

See Table

3.1

p.29

-10 8,9 9,4

G25 -10 8,7 9,0

G25.1 -10 10,5 10,9

G25.3 -10 8,8 9,2

G27 -10 9,2 9,4

G2.350 -10 9,1 9,4

G30 -10 10,4 10,6

G31 -10 10,1 10,4

LPG -10 9,8 10,2

A tolerance of ±0,3% is applied to all values of CO

2

percentage in fumes.

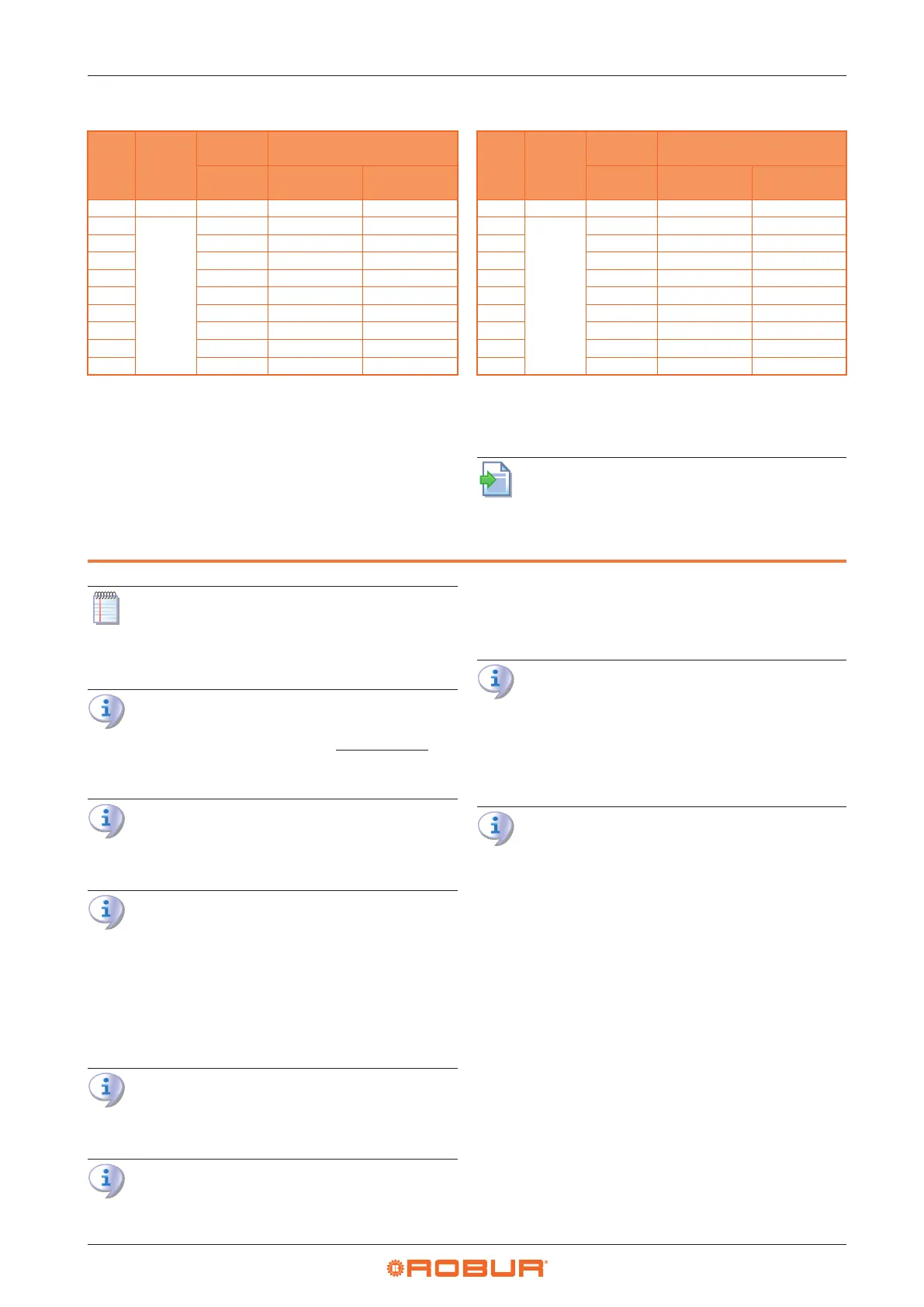

Table5.7 R80 gas valve setting table

Gas

Gas

network

pressure

Oset

pressure

CO

2

percentage in fumes

nominal

Minimal heat

input

Nominal heat

input

Type mbar Pa % %

G20

See Table

3.1

p.29

-10 9,1 9,3

G25 -10 8,7 9,2

G25.1 -10 10,5 10,9

G25.3 -10 8,9 9,3

G27 -10 8,8 9,2

G2.350 - - -

G30 -10 10,2 10,5

G31 -10 9,9 10,2

LPG -10 9,7 10,1

A tolerance of ±0,3% is applied to all values of CO

2

percentage in fumes.

5.3 GAS CHANGEOVER

For gas change instructions, refer to the rele-

vant documentation.

6 NORMAL OPERATION

This section is for the end user.

6.1 WARNINGS

General warnings

Prior to using the appliance carefully read the

warnings in Chapter III.1

p. 4

, providing impor-

tant information on regulations and on safety.

First startup by TAC

First start-up may exclusively be carried out by a

Robur TAC (Chapter 5

p.42

).

Never power the appliance o while it is run-

ning

NEVER power the appliance o while it is running

(except in the event of danger, Chapter III.1

p. 4

),

since the appliance or system might be damaged.

6.2 SWITCH ON AND OFF

Routine switching on/o

The appliance may exclusively be switched on/o

by means of the suitably provided control device.

Do not switch on/o with the power supply

switch

Do not switch the appliance on/o with the power

supply switch. This may be harmful and dangerous

for the appliance and for the system.

Checks before switching on

Before switching on the appliance, ensue that:

gas valve open

appliance electrical power supply (main switch ON)

connection and any necessary power supply of the

control device

After a long period of unit inactivity or at the rst

start-up, it may be necessary to repeat the ignition

operation due to the presence of air in the gas

piping.

6.2.1 OCDS012 1-key basic control

Space heating activation

1. Ensure that contact 1-3 is closed by the factory in-

stalled temporary jumper. If a summer/winter selector

switch (Paragraph 4.4.6.2

p. 39

) has been installed,

ensure that the selector switch is in the "winter" posi-

tion (contact 1-3 closed).

2. Switch on Z9 contact using the provided control de-

vice (thermostat, chronothermostat or voltage-free

contact).

3. After the purge time (around 40 seconds), the gas so-

lenoid valve opens and the burner ignites.

4. When the ame is detected, the control box keeps the

gas valve open.

5. Otherwise, the control unit will try the ignition again

3 times, after the appropriate purge time. If the ame

Loading...

Loading...