4

Rosco Maximizer 3B Asphalt Distributor 4-15

Specications

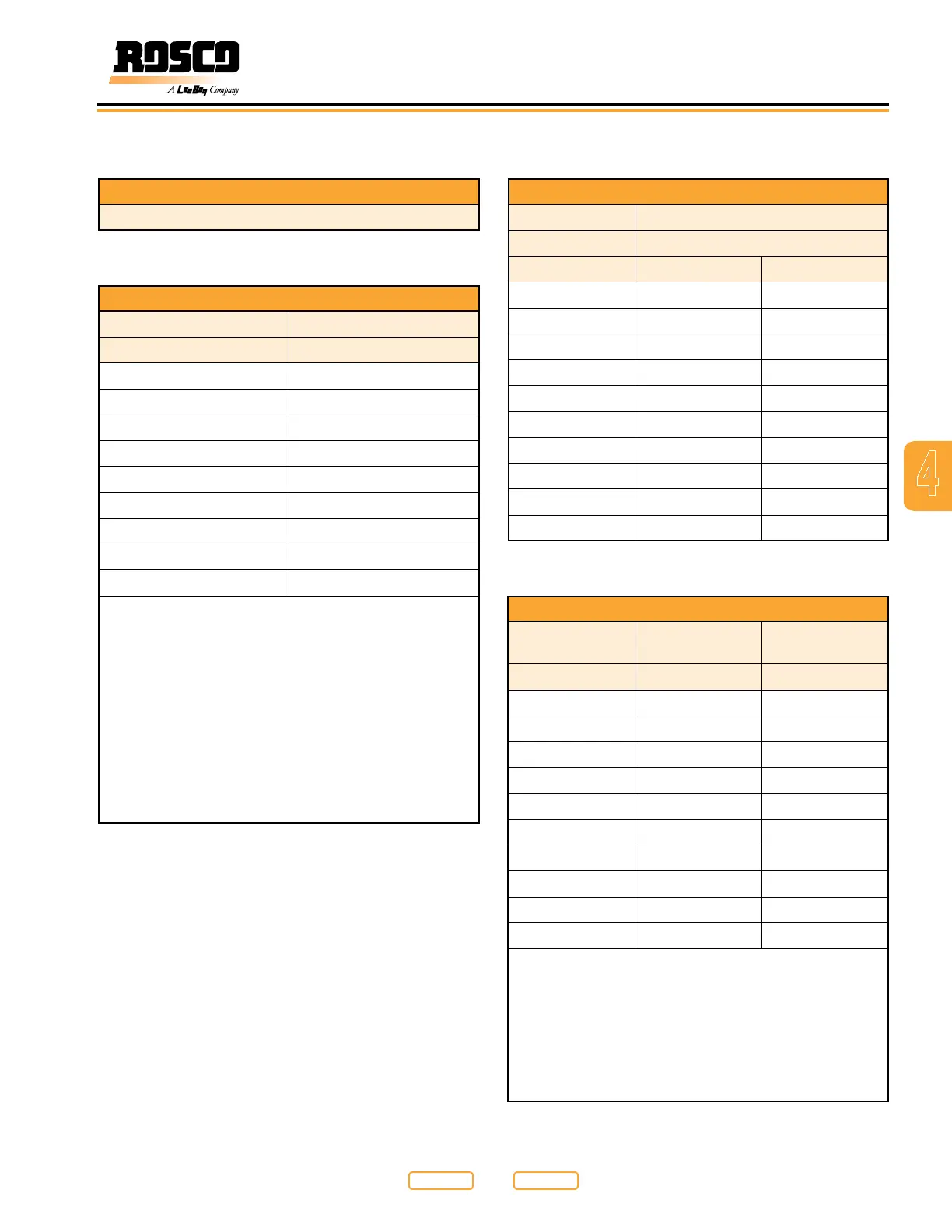

Table 4-14. Torque Specications For BSP 30°

Inverted Cone and JIS Coupling Terminations

BSP 30° Inverted Cone and JIS

Dash Size Torque

mm ft-Lb

1/16 Inch Min Max

-2 7 9

-4 11 18

-6 19 28

-8 30 36

-10 37 44

-12 50 60

-16 79 95

-20 127 152

-24 167 190

-32 262 314

Table 4-15. Flats Method Values For Selected

Terminations

Flats Method Values

Termination

Type

Dash Size Flats

1/16 Inch

JIC 4 1.5 - 1.75

JIC 6 1.0 - 1.5

JIC 8 1.5 - 1.75

JIC 10 1.0 - 1.5

JIC 12 1.0 - 1.5

JIC 16 .75 - 1.0

JIC 20 .75 - 1.0

JIC 24 .75 - 1.0

JIC 32 .75 - 1.0

JIS 4 .5 - 1.5

1. Seal faces must be in contact and the tting fully

hand tightened before marking ats.

2. Flats method is most accurate for the rst

assembly cycle, for multiple disassembly/

assembly cycles torque values are more reliable.

3. Tightening 2 ats or more is analogous to sever

over torque and may damage seal faces.

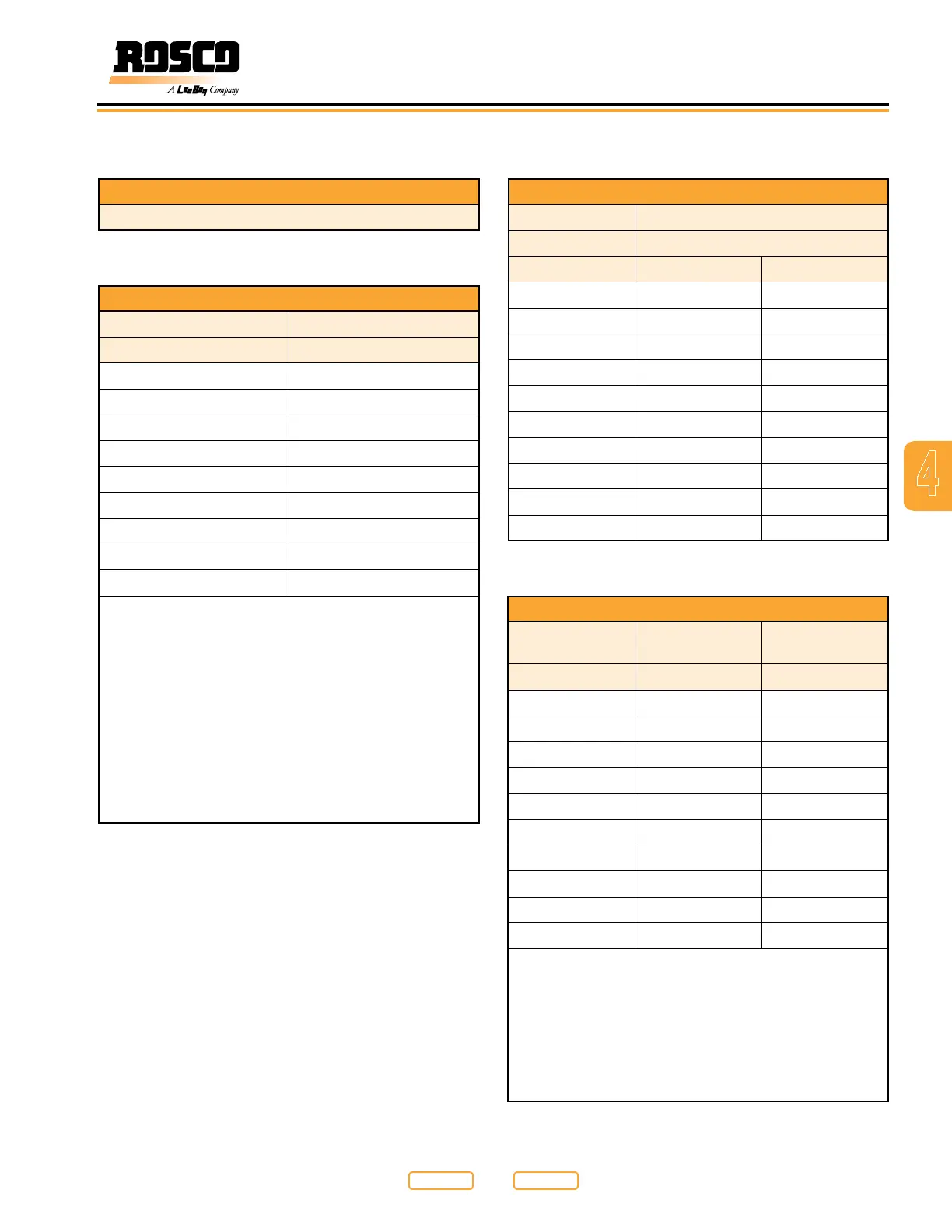

Table 4-12. Torque Specications For SAE Male

Flareless Assembly (MFA)

SAE Male Flareless Assembly (MFA)

After hand tight rotate nut one full turn (8 ats)

Table 4-13. Torque Specications For NPTF Dry Seal

Pipe Threads

NPTF

Dash Size Max Torque

1/16 Inch ft-Lb

-2 20

-4 25

-6 35

-8 45

-12 55

-16 65

-20 80

-24 95

-32 120

1. The torque values obtained from tightening pipe

threads can vary considerably depending on

thread condition. Adequate sealing can occur at

values much lower than the maximum values listed

above. Only enough torque to achieve adequate

sealing should be used.

2. When using a male tapered pipe thread with a

female straight or parallel pipe thread, maximum

values are 50% of those listed in the table.

3. If thread sealant is used, maximum values shown

should be decreased by 25%.

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...