7

Rosco Maximizer 3B Asphalt Distributor 7-9

Maintenance

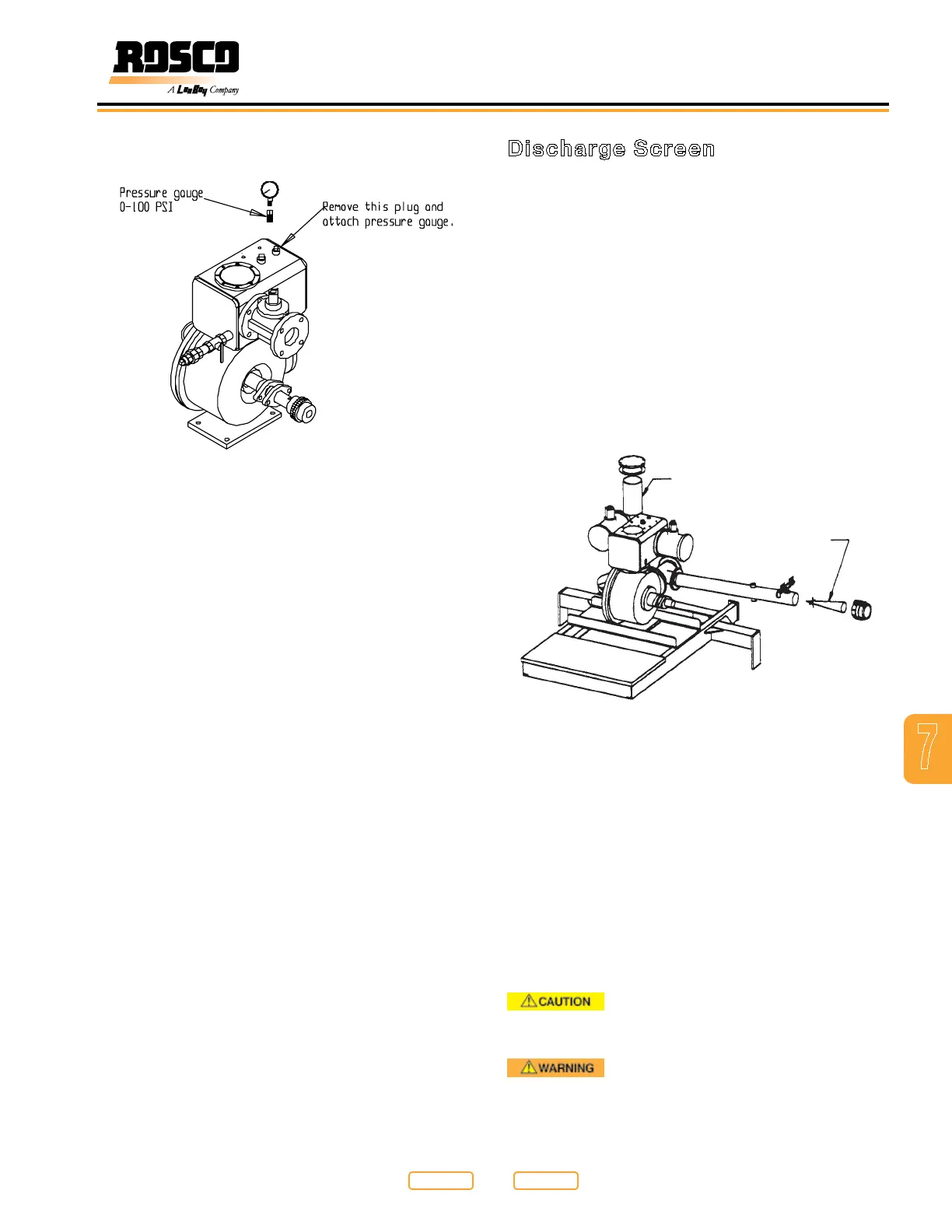

Discharge Screen

The discharge screen (Figure 7-5) prevents large

contaminants from reaching the nozzles. It is located

on the outlet side of the pump manifold weldment box.

Clean the screen monthly during the working season.

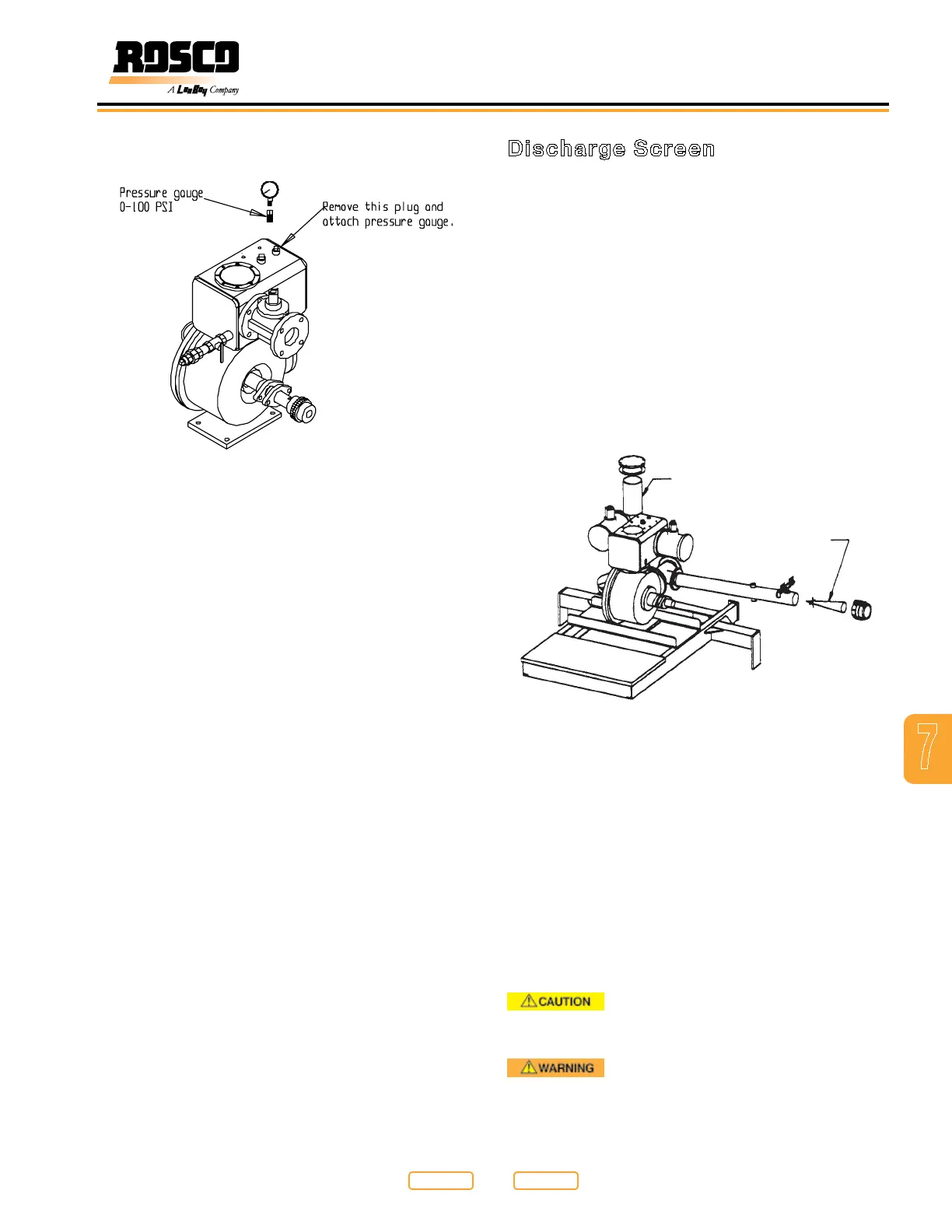

To clean the screen, follow this procedure:

1. Stop the engine, place all controls in neutral, set the

park brake and remove ignition key.

2. Be sure the tank is empty and the circuit is washed

out.

3. Allow machine to cool to the touch.

4. Remove bolts holding access cover to pump

weldment. Remove the access cover from the

pump weldment box.

LOAD SCREEN

DISCHARGE SCREEN

Discharge Screen & Load Screen

Figure 7-5

5. Remove any trash or debris that has become

caught in the screen.

6. If the screen is damaged in any way, replace it using

genuine Rosco parts.

7. Use a screwdriver or putty knife to remove the old

gasket on the cover and housing.

8. Use Rosco high temperature gasket sealant (part

#33384) under this cover to prevent leakage.

9. Install the cover and tighten the mounting bolts to

their specied torque (28 Ft/Lbs).

Always wear protective clothing,

gloves and a face shield. Contact with hot asphalt

can cause severe burns.

DO NOT SMOKE around the machine.

Fuel, asphalt material and the fumes from either

can explode when exposed to ame or heat from

smoking or other sources.

8. Remove the valve cap that covers the adjusting

screw.

Test gauge placement

Pressure Gauge

Figure 7-4

9. Slowly turn the adjusting screw in to increase the

relief pressure and turn it out to decrease pressure.

The screw height should extend 9/16 inch (14 mm)

out of the bonnet casting for the needed pressure.

10. If proper pressure cannot be achieved, valve may

need to be cleaned or replaced.

11. To clean the relief valve, disconnect the dump line

from the asphalt pump housing. Remove the relief

valve from the asphalt pump housing.

12. Use cleaning solvent or release agent to thoroughly

clean the valve. Dispose of cleaning material

according to local, state and federal regulations.

13. Be sure nothing is stuck under the poppet. Check

that the spring moves the poppet easily and seats it

rmly in the base.

14. If any components are damaged or broken, replace

the valve.

15. Set the adjusting screw to extend 9/16 inch out of

the bonnet casting.

16. Attach to the pump housing and connect the dump

line using new gaskets.

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...